A ejection and demoulding mechanism applied to stamping dies

A technology of demolding mechanism and stamping die, applied in forming tools, manufacturing tools, push-out equipment, etc., can solve the problems of rapid adjustment of the ejection force, deformation of parts, poor practicability, etc. Sexual, structurally sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

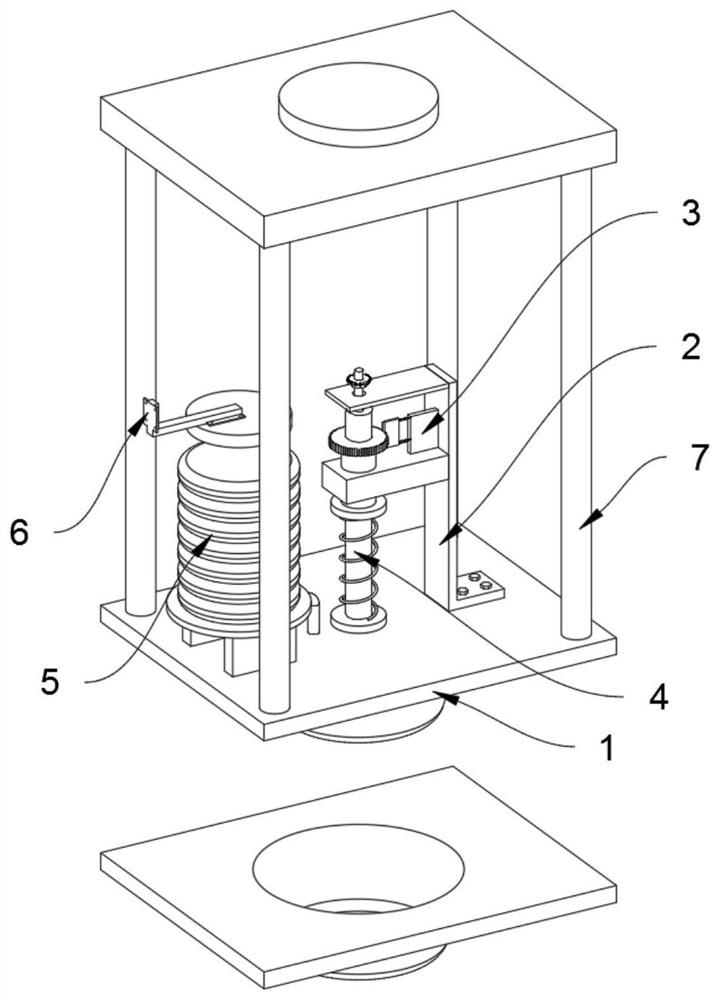

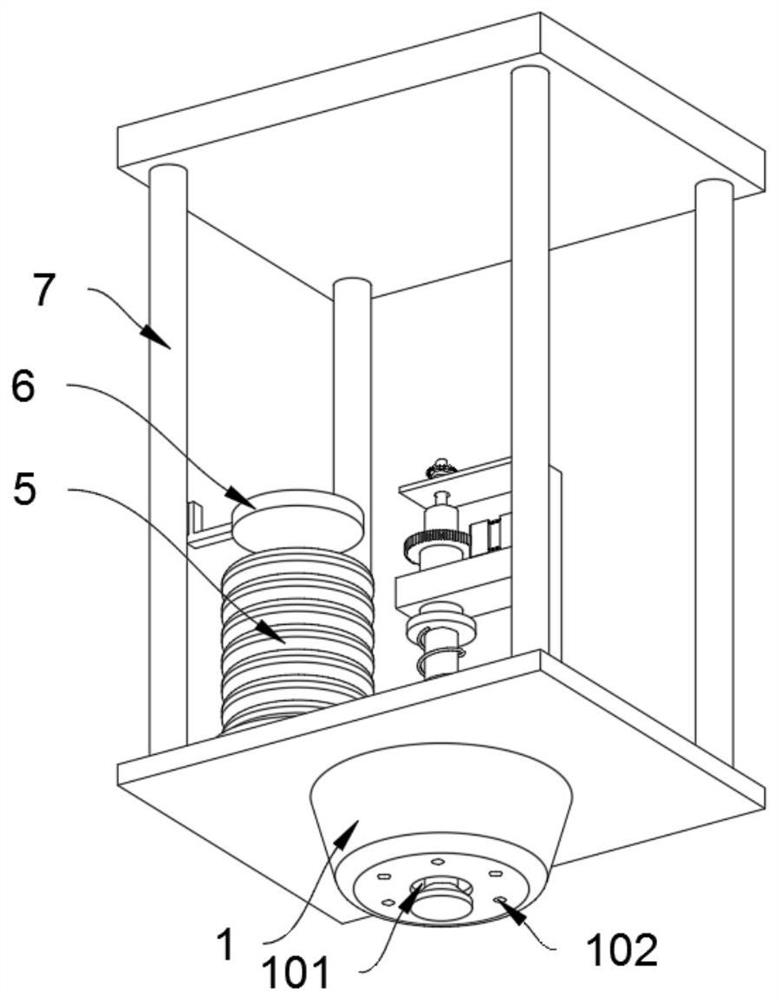

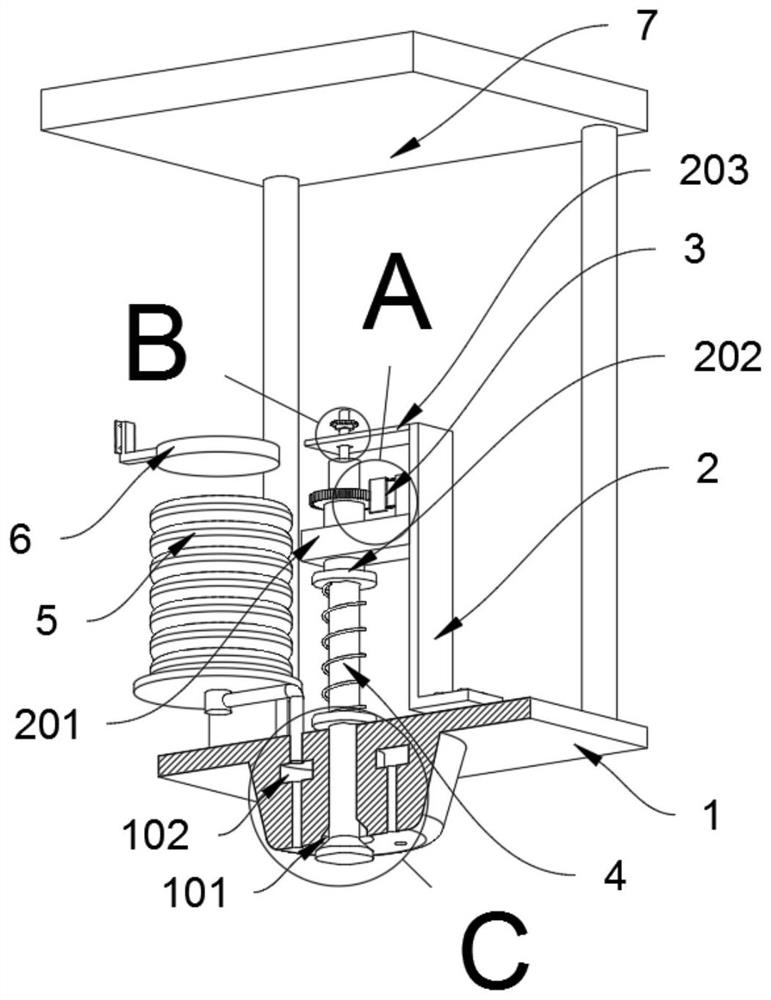

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The invention provides an ejection and demoulding mechanism applied to stamping dies, which includes a punch 1 and a pressure block 6; the top surface of the punch 1 is fixedly connected with a support frame 2 by bolts, and the top surface of the punch 1 is also fixed by bolts The connection has an elastic bayonet 3; refer to eg image 3 with Figure 5 , the support frame 2 includes an adjustment seat 201, an adjustment nut tube 202 and a support plate 203, a rectangular block-shaped adjustment seat 201 is welded on the left end of the support frame 2, and an adjustment nut tube 202 is threaded on the adjustment seat 201; the support frame 2 A support plate 203 is welded above the left end surface, and a circular hole is opened on the support plate 203; a push rod structure 4 is slidably connected to the inside of the punch 1, and a compressed gas cylinder 5 is installed on the top of the punch 1, And the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com