Split type wheel hub motor with pneumatic tire and vacuum tire convenient to disassemble and assemble

A technology for in-wheel motors and tubeless tires, which is applied in power units, transportation and packaging, motion deposition, etc., can solve the problems of high replacement cost, troublesome replacement process, and deformation of wheel hubs, so as to reduce replacement costs, reduce maintenance troubles, and improve replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

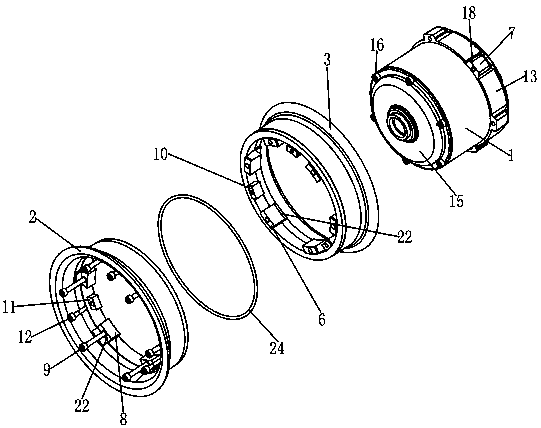

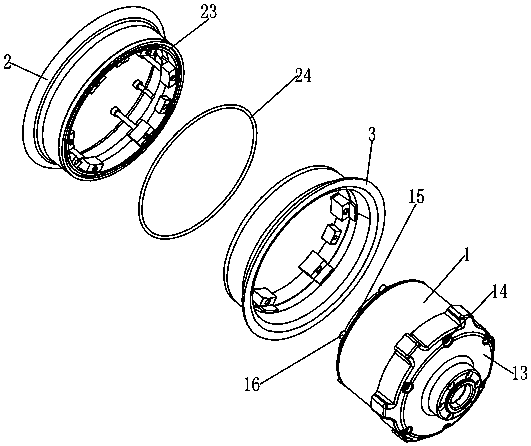

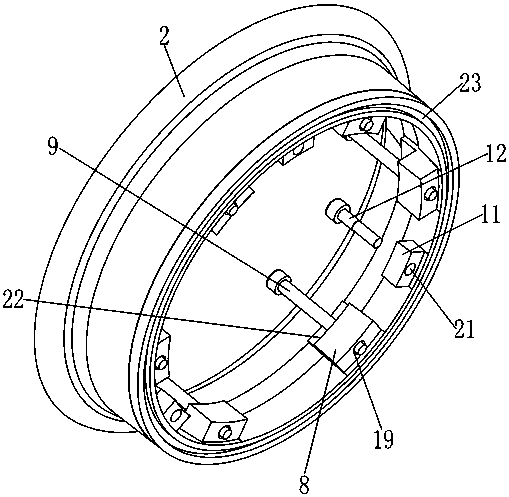

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0022] see Figure 1 to Figure 6 , the present invention provides a split hub motor for easy disassembly and assembly of pneumatic tires and tubeless tires. body 3; the right end surface of the left hub body 2 is fitted with the left end surface of the right hub body 3, and a sealing device is arranged between the right end surface of the left hub body 2 and the left end surface of the right hub body 3; the left hub body 2 and the right hub body The body 3 is combined to form a hub 4, and the hub 4 is provided with an annular tire mounting groove 5; the inner wall of the left side of the right hub body 3 is provided with a number of first fixed blocks 6 that are evenly distributed around the circumference; the motor body 1 right The outer wall of the part is provided with a number of second fixed blocks 7 corresponding to the positions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com