A workpiece processing device

A technology for processing equipment and workpieces, applied in the field of transportation, can solve the problems of complex processing procedures and inability to handle workpieces, and achieve the effects of simplified processing procedures, reasonable device structure design, and high overall structure integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

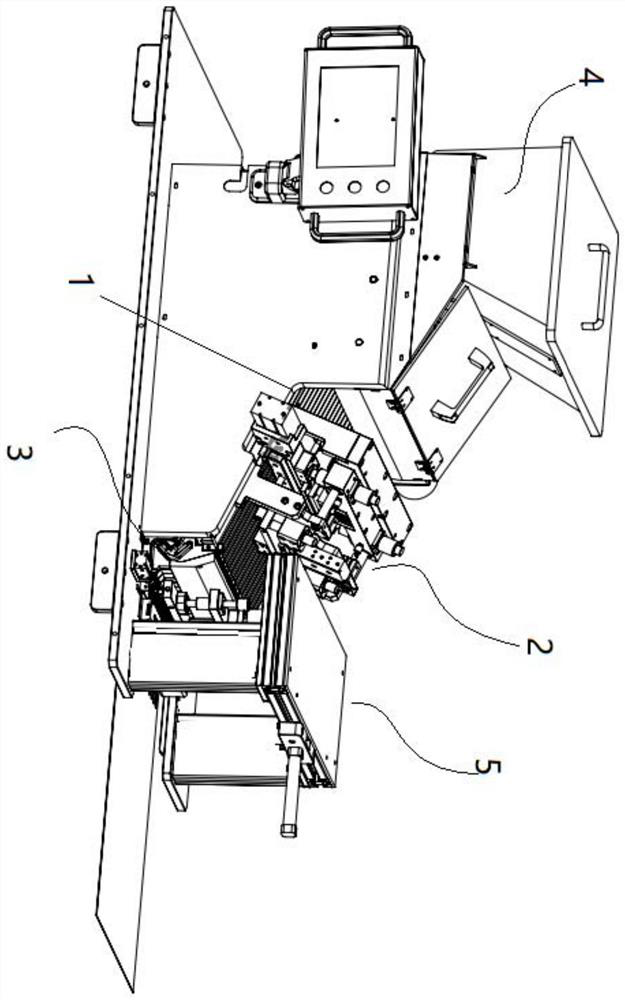

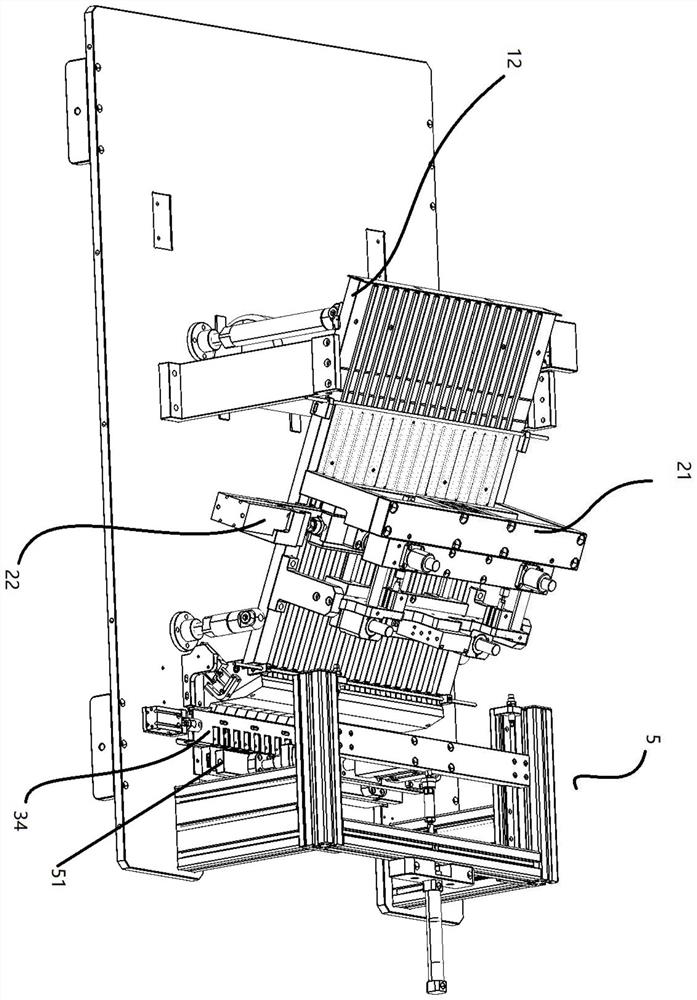

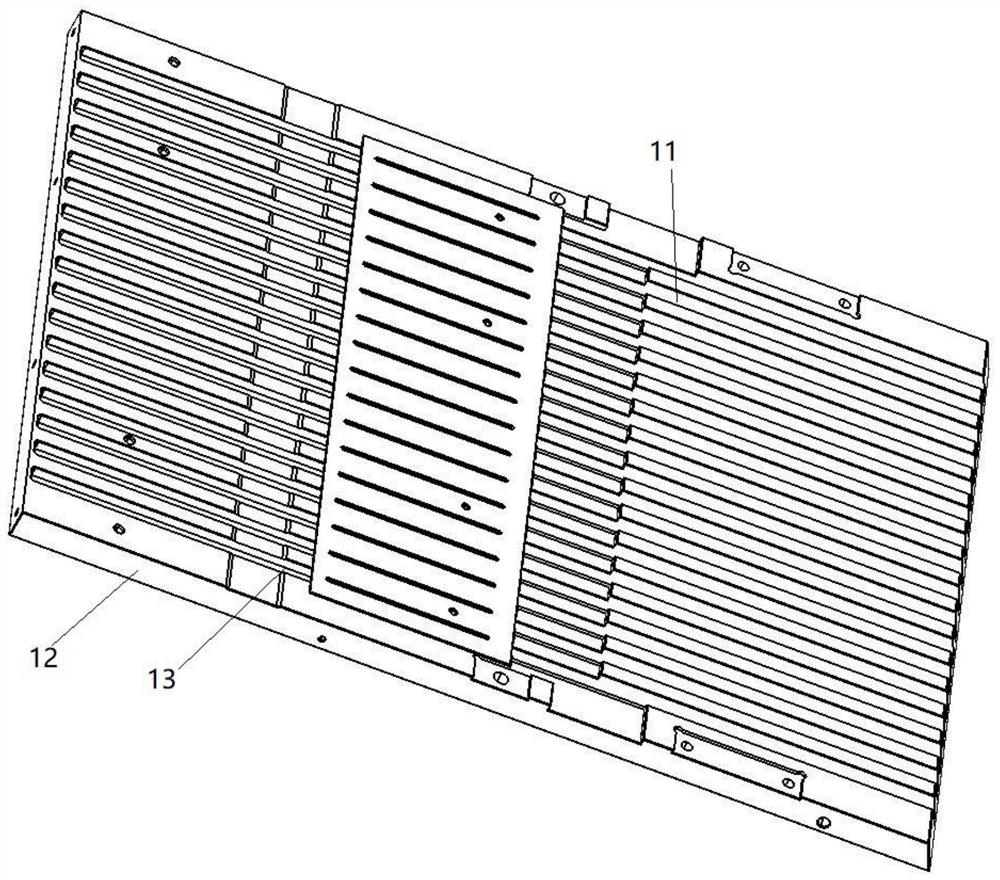

[0062] Embodiments of the present invention provide a workpiece processing device, such as Figure 1-Figure 3 As shown, the workpiece processing equipment includes a conveying device 1 and a feeding device 4, a separating device 2, a reversing device 3 and a discharging device 5 arranged sequentially along the conveying device 1, as figure 2 As shown, specifically, the transmission device 1 includes a transmission channel 11 and a transmission substrate 12 for transmitting workpieces, and a plurality of sliding material grooves 13 are arranged on the transmission substrate 12, and the sliding material grooves 13 form the above-mentioned transmission channel 11; The transmission substrate 12 is connected between the above-mentioned reversing device 3 and the above-mentioned feeding device 4, and its end close to the above-mentioned feeding device 4 is higher than the end close to the above-mentioned reversing device 3, so that the workpiece is transported along the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com