A kind of glass fiber production and processing technology

A glass fiber and processing technology, applied in the field of glass fiber production and processing technology, can solve the problems of poor glass fiber infiltration effect and insufficient infiltration of glass fiber, and achieve the effect of good infiltration effect and guaranteed infiltration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

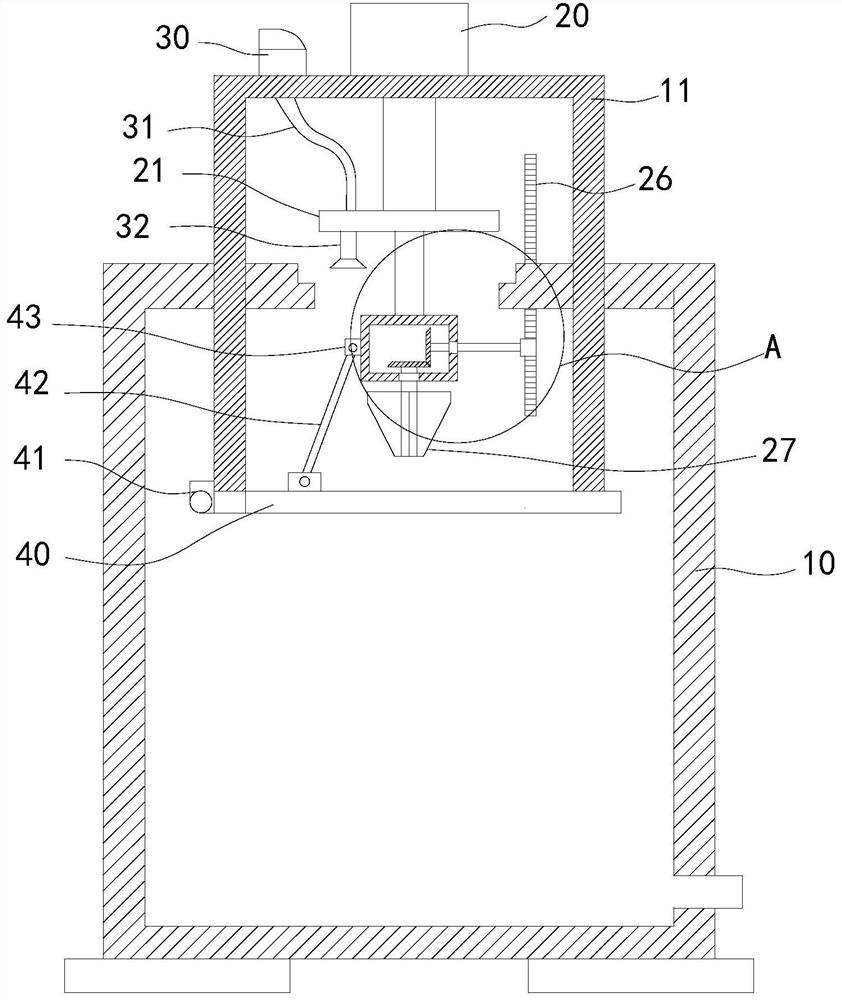

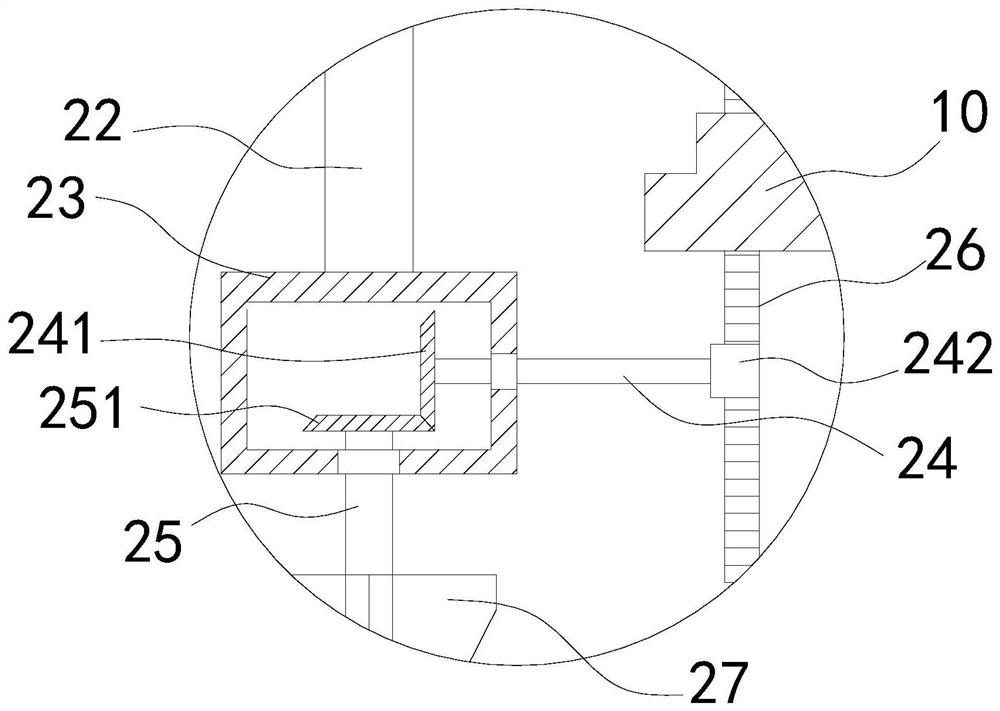

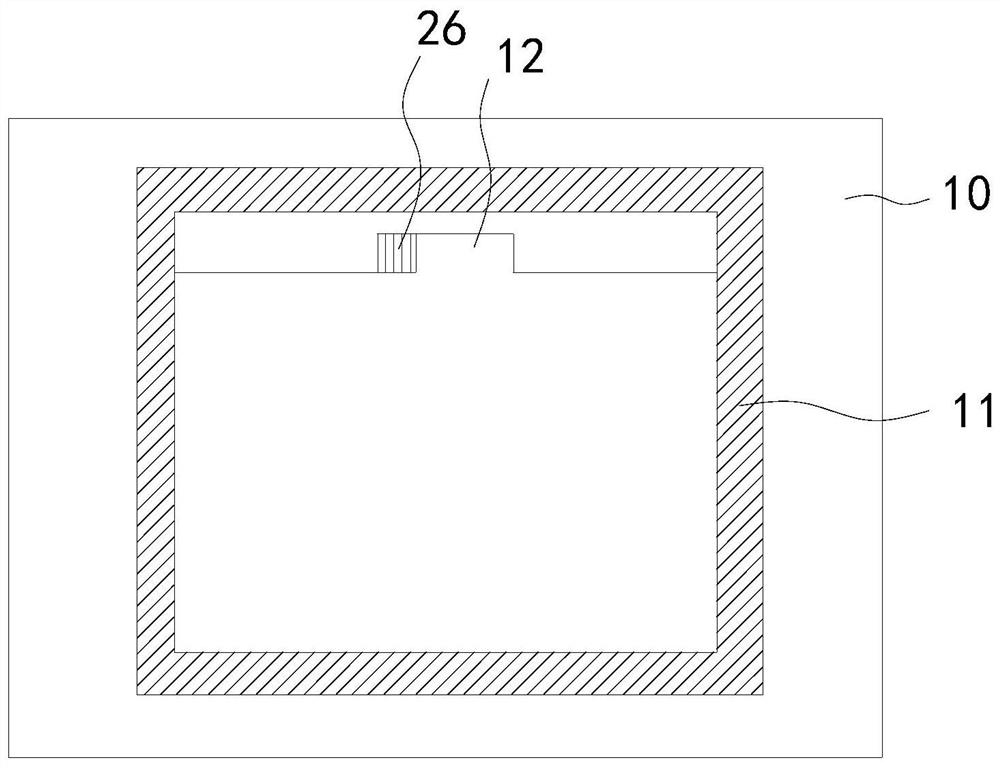

[0030] like figure 1 , figure 2 , image 3 As shown, the present invention provides a glass fiber production and processing technology, comprising the following steps:

[0031] (1), put the raw material into the crucible kiln and melt to form liquid glass;

[0032] (2), put the liquid glass melted in (1) into the fiber forming equipment to form filamentous glass fibers;

[0033] (3), using the fiber forming equipment in (2) to cool the filamentous glass fibers and wind them into bundles;

[0034] (4), place the glass fiber after winding in (3) on the soaking equipment for soaking treatment;

[0035] (5), put the glass fiber after soaking into the warehouse in (4);

[0036] The infiltration equipment used in this process includes:

[0037] The box body 10, an infiltration liquid is arranged in the box body 10, a casing 11 is embedded in the top of the box body 10, and a transparent window can be provided on the side wall of the casing 11 in order to facilitate dischargin...

Embodiment 2

[0045] like figure 1 , figure 2 , image 3 As shown, the present invention provides a glass fiber production and processing technology, comprising the following steps:

[0046] (1), put the raw material into the crucible kiln and melt to form liquid glass;

[0047] (2), put the liquid glass melted in (1) into the fiber forming equipment to form filamentous glass fibers;

[0048] (3), using the fiber forming equipment in (2) to cool the filamentous glass fibers and wind them into bundles;

[0049] (4), place the glass fiber after winding in (3) on the soaking equipment for soaking treatment;

[0050] (5), put the glass fiber after soaking in (4) into the warehouse;

[0051] The infiltration equipment used in this process includes:

[0052] The box body 10, an infiltration liquid is arranged in the box body 10, a casing 11 is embedded in the top of the box body 10, and a transparent window can be provided on the side wall of the casing 11 in order to facilitate dischargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com