Low-smoke halogen-free flame-retardant sheath material having good cold resistance and used for cable and preparation method of sheath material

A flame retardant sheath, high-performance technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of cracking service life, embrittlement and decline of the outer sheath, and achieve good cold resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

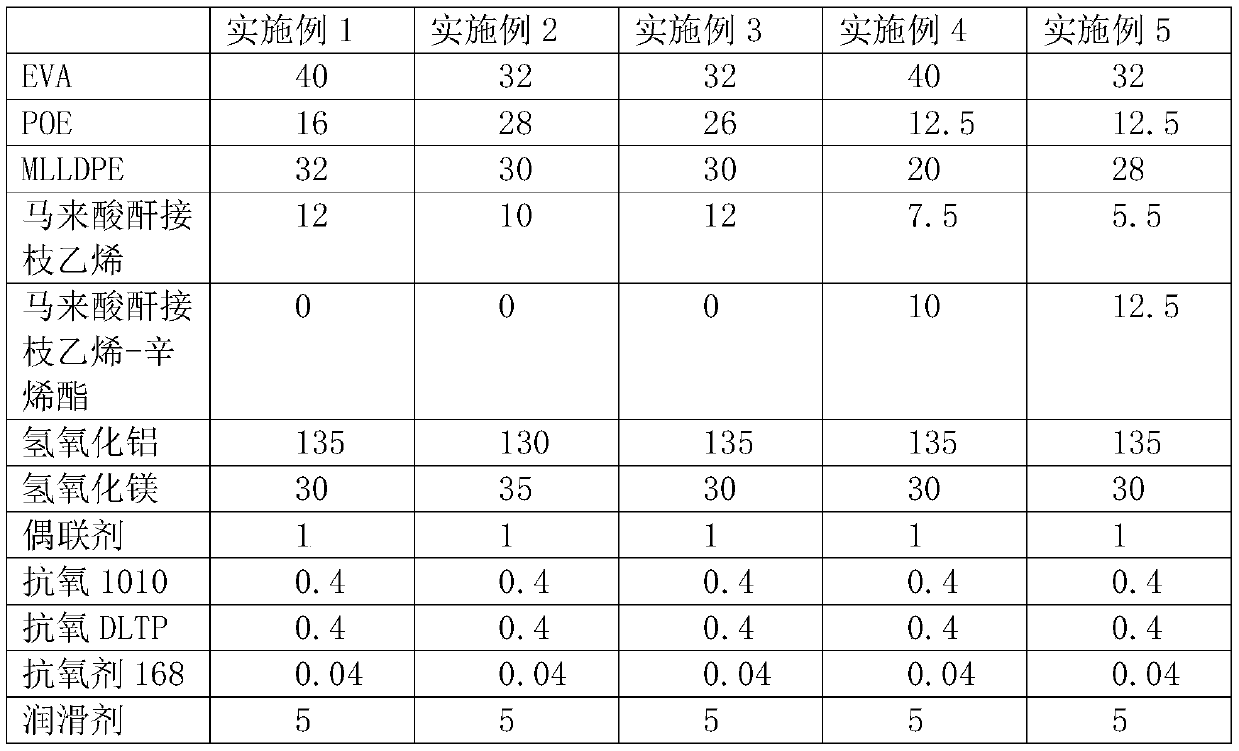

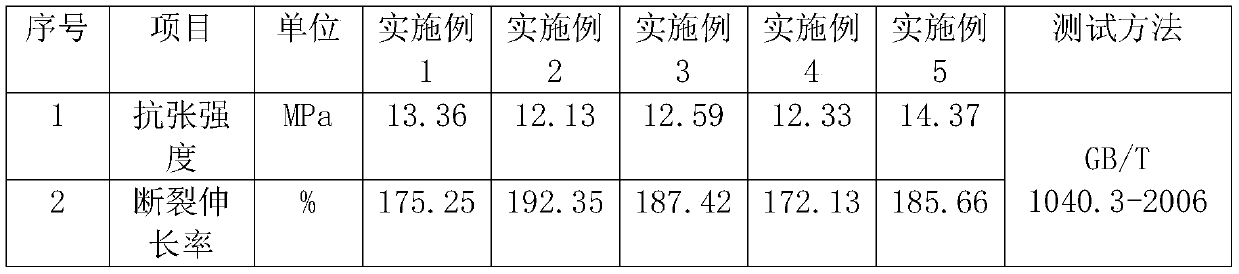

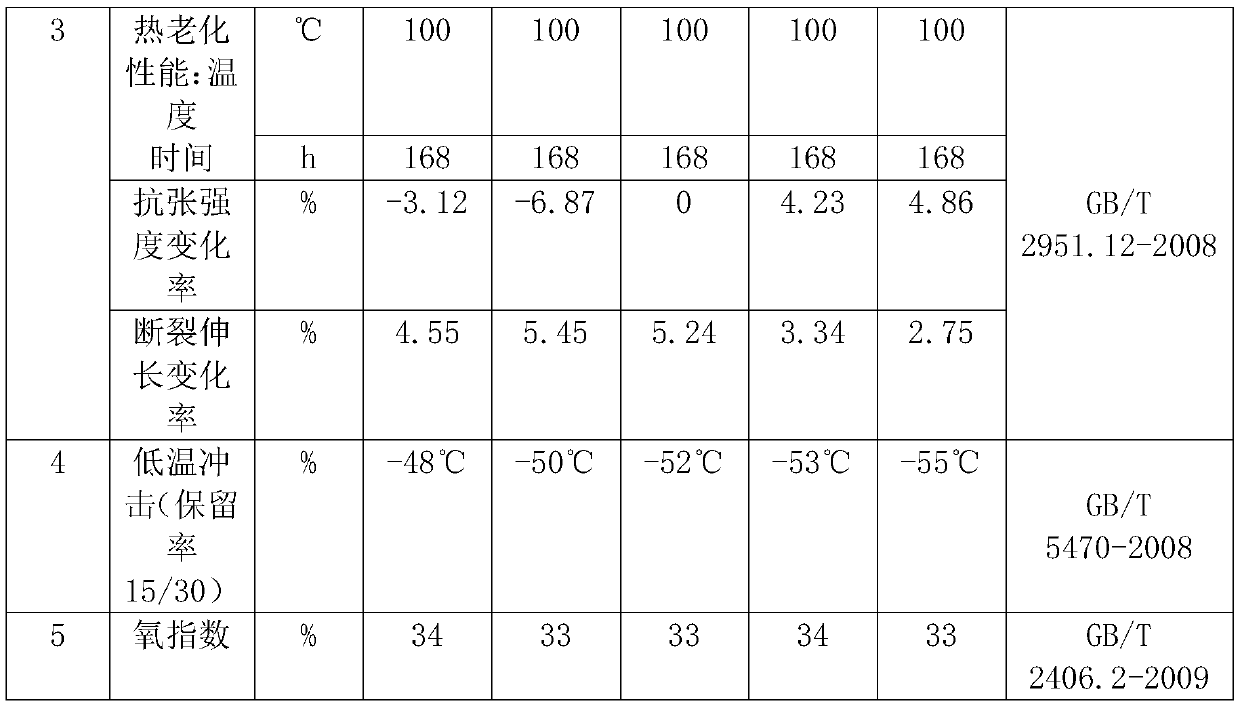

Examples

Example Embodiment

[0037] The preparation method of the low-smoke halogen-free flame-retardant sheath material for cables with good cold resistance of the above embodiment is characterized in that it comprises the following steps:

[0038] Weigh the raw materials, clean and preheat the internal mixer.

[0039] Add polyolefin resin, compatibilizer, flame retardant, lubricant, antioxidant, and coupling agent to the internal mixer in sequence, and mix for 20-30 minutes to make the components evenly mixed.

[0040] Use a double cone feeder to plasticize the mixed masterbatch through a twin-screw / single-screw double-stage mixing unit extruder at an extrusion temperature of 130~140℃, granulation, air cooling, vibrating screening, and packaging .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com