Mining cable with water-blocking isolation layer

An isolation layer and water-blocking technology, applied in the direction of power cables with shielding layer/conductive layer, bendable cables, insulated cables, etc., can solve the problem of cracking of cable sheath, unsuitable construction and laying in winter, unusable cables, etc. problems, achieve excellent cold resistance and improve radial water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

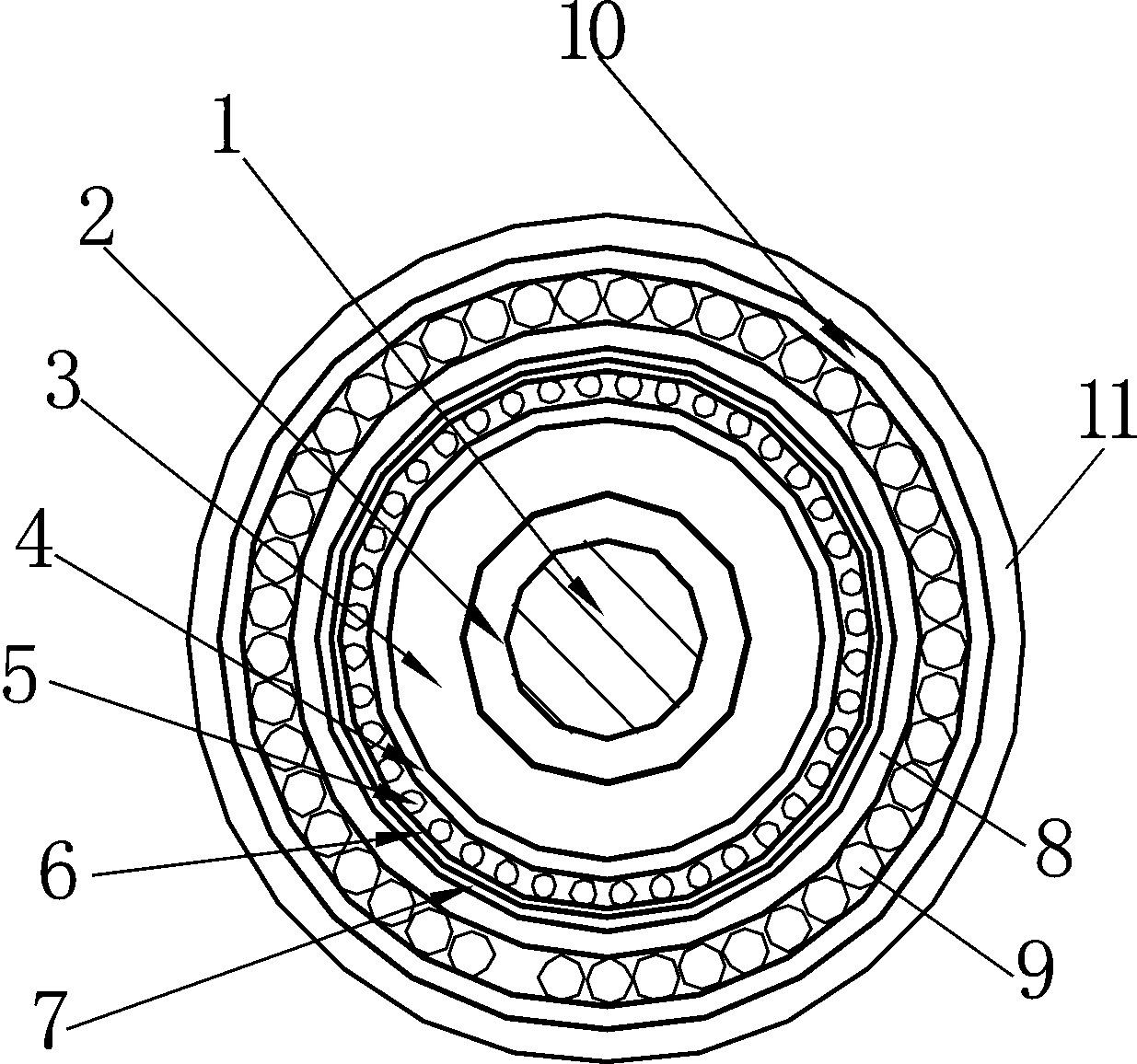

[0010] Such as figure 1 As shown, the coal mine cable with a water-blocking isolation layer has a cross-sectional area of 240mm from the inside to the outside 2 The wire core 1, the conductor shielding layer 2, the insulating layer 3, the insulating shielding layer, the tape 7 and the outer sheath 11 are composed, and the insulating layer 3 is made of cross-linked polyethylene material, and its thickness is not less than 23mm. The insulating shielding layer is composed of a non-metallic semiconductive layer 4 and a metal layer 5 from the inside to the outside, wherein the nonmetallic semiconductive layer 4 is made of extruded cross-linked adhesive semiconductive material, and the metal layer 5 is made of copper Wire shielding, the surface of the copper wire shielding is provided with reversely wrapped copper wires or copper strips 6, and the average gap between the winding wires in the copper wire shielding should not be greater than 4mm.

[0011] The outer periphery of sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com