Drainage and noise reduction structure of washing machine and washing machine

A washing machine and drainage pipe technology, applied in the field of washing machines, can solve the problems of poor noise reduction effect, lack of good experience, inconvenient cleaning, etc., and achieve the effect of reducing impact and good sterile use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

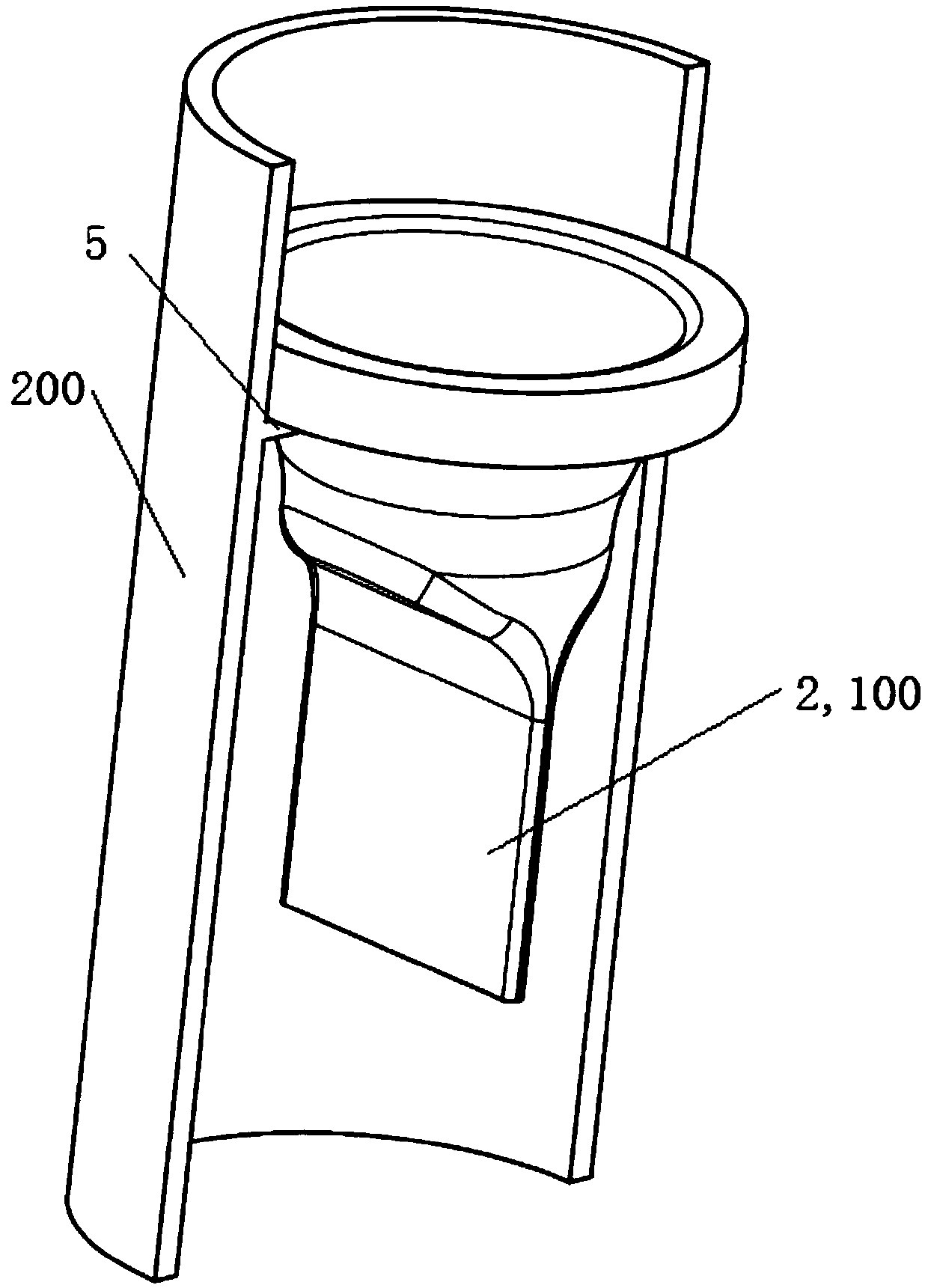

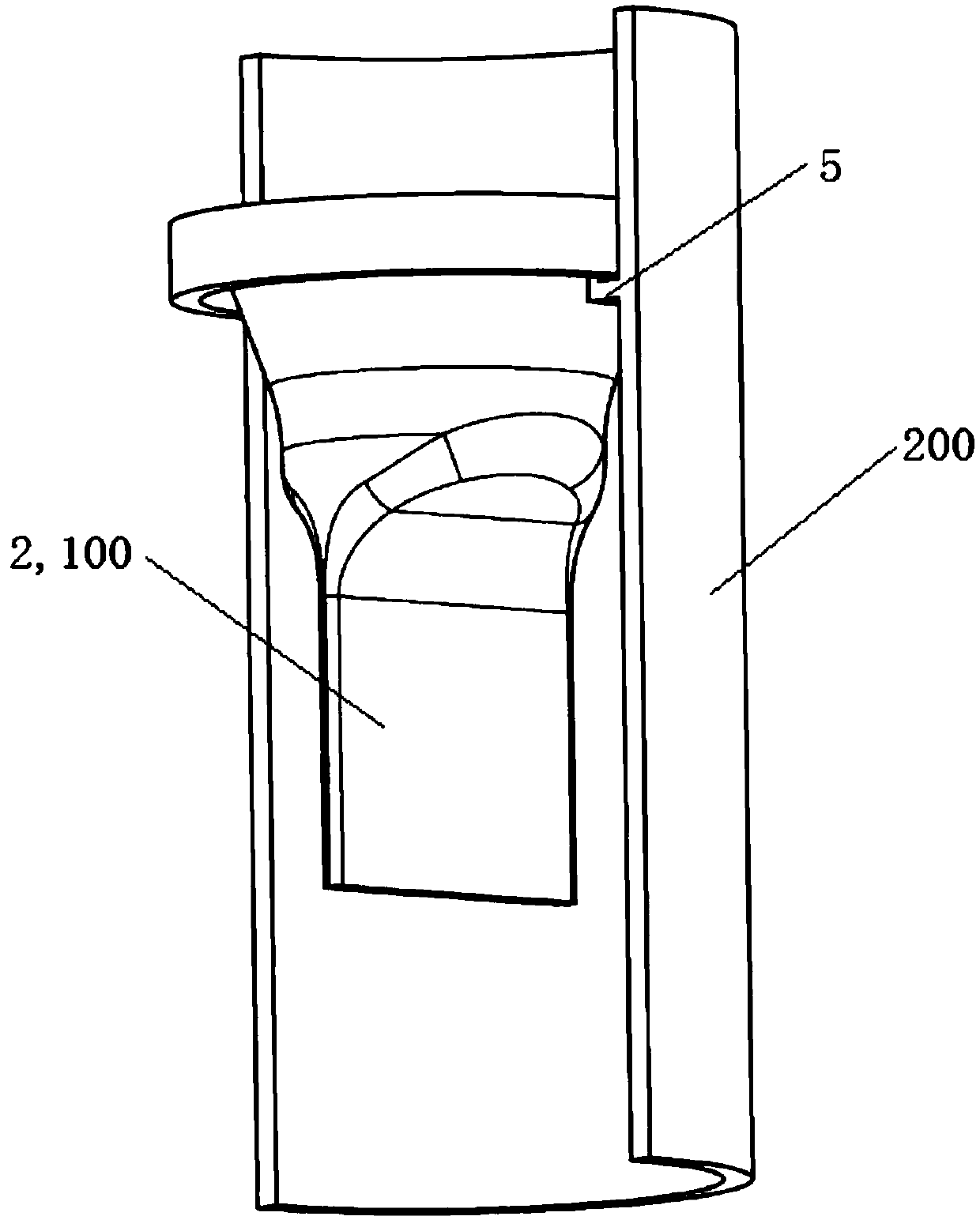

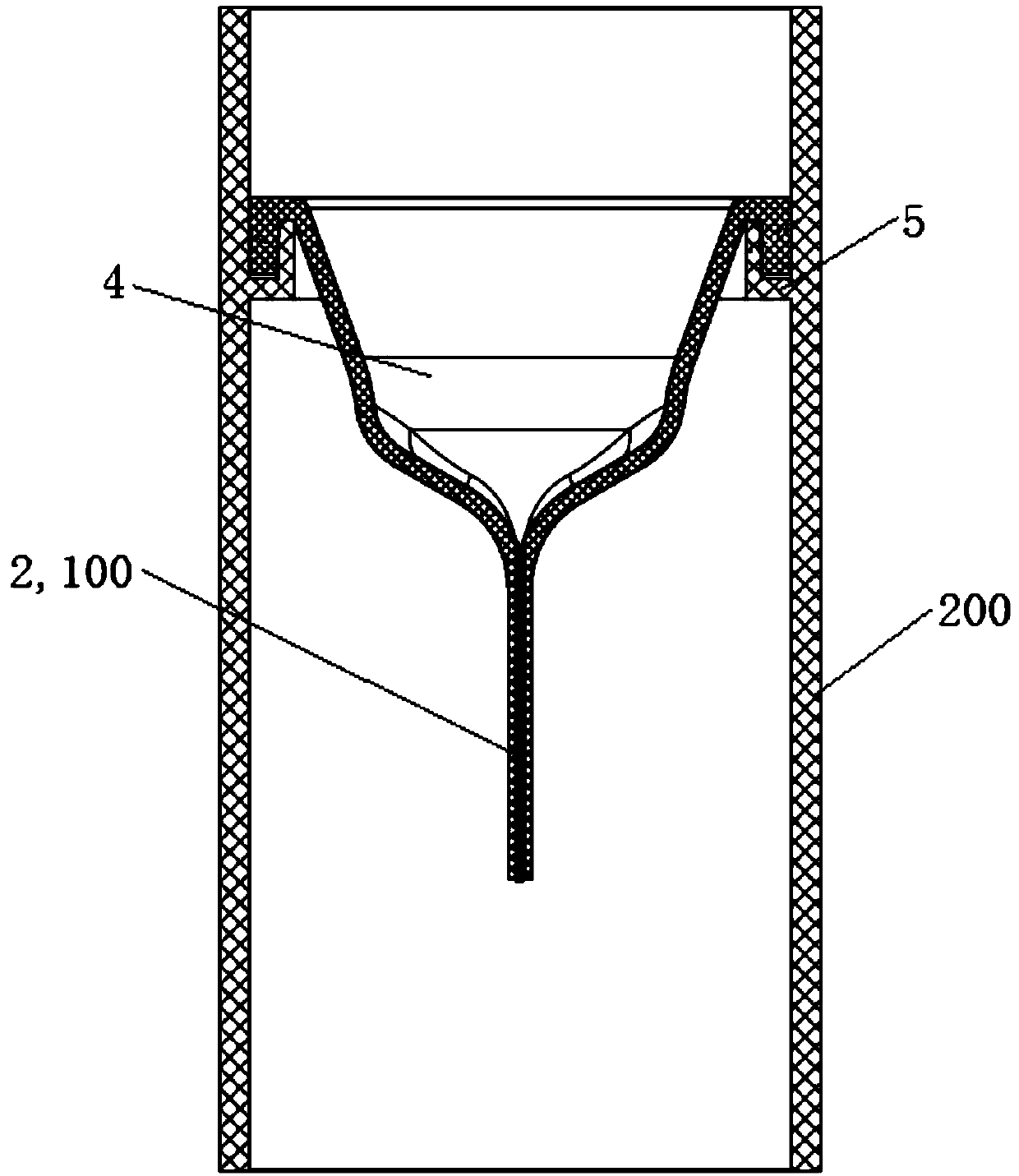

[0042] Such as Figure 1 to Figure 6 As shown, this embodiment introduces a washing machine drainage noise reduction structure 10. The drainage noise reduction structure 100 includes a telescopic hose 2 that can shrink and expand in the radial direction. The channel 4 and the telescopic hose 2 are in a tightened state in a free state to close the drainage channel 4 , and the telescopic hose 2 expands outward against its own elastic force to open the drainage channel 4 when the washing water flows through. During the drainage process of the washing machine, the washing water flows through the drainage noise reduction structure 100, and the telescopic hose 2 of the drainage noise reduction structure 100 expands under the action of water flow pressure to open the drainage channel 4 for the washing water to pass through; during the non-drainage process of the washing machine , the telescopic hose 2 shrinks to close the drainage channel.

[0043] In this embodiment, the telescopic...

Embodiment 2

[0047] The difference between this embodiment and the first implementation above is that: Figure 7 to Figure 8 As shown, in this embodiment, the drainage noise reduction structure 100 further includes an installation part 1 , which is fixedly connected to the inner circumference of the drain pipe 200 , and the telescopic hose 2 is fixedly installed inside the drain pipe 200 through the installation part 1 .

[0048] In this embodiment, a hollow flow channel 8 is provided inside the installation part 1, the inlet of the hollow flow channel 8 communicates with the drain pipe 200 upstream of the installation part 1, and the outlet of the hollow flow channel 8 communicates with the water inlet of the drainage channel 4. The washing water flows into the drainage channel 4 from the inlet of the hollow flow channel 8 of the installation part 1, the water outlet end of the telescopic hose 2 expands under the action of the water flow pressure, and the washing water flows out from the w...

Embodiment 3

[0054] Such as Figure 7 to Figure 8 As shown, in this embodiment, the washing machine drain pipe 200 is provided with an adapter 5 fixedly connected to the installation part 1, and the installation part 1 is fixedly connected to the inner wall of the drain pipe through the adapter 5, that is, the drainage noise reduction structure 100 The adapter piece 5 is fixedly connected to the inner wall of the drain pipe 200 to avoid displacement of the drain noise reduction structure 100 under the impact of water flow.

[0055] In this embodiment, the adapter 5 includes a circle of extension ribs 6 protruding radially along any section of the drain pipe 200, the outer circumference of the extension ribs 6 is fixedly connected with the inner wall of the drain pipe 200, and the inner circumference is provided with vertical clips. The holding rib 7, the clamping rib 7 and the inner wall of the drain pipe 200 form a clamping gap with a certain distance, the clamping gap is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com