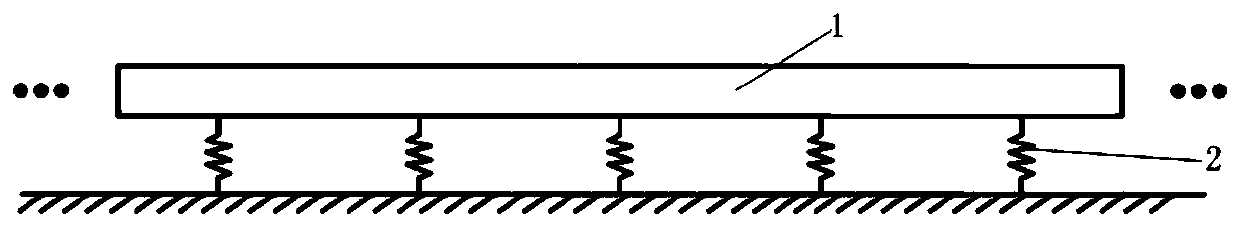

Improved steel rail vibration absorption system and method for improving vibration absorption performance

A system performance, rail technology, applied in the field of rail vibration and rail transit, can solve the problems of inability to spread, unsatisfactory vibration reduction effect, etc., and achieve good vibration absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

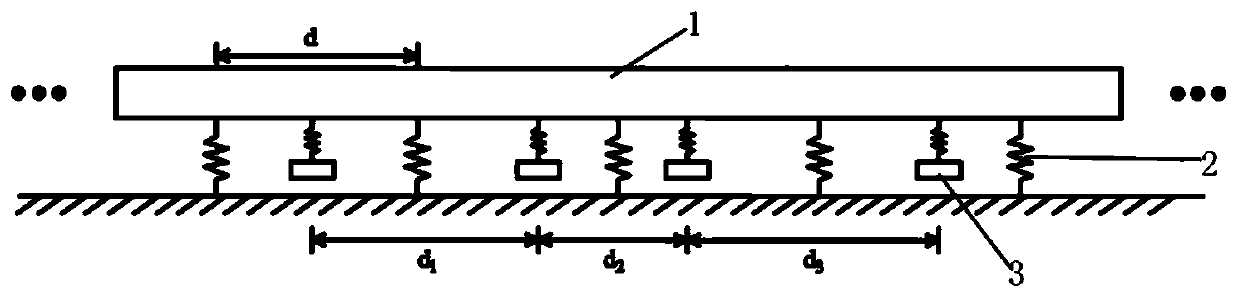

[0058] (1) Measure the fastener spacing with a tape measure, and the measured fastener spacing is 0.625m;

[0059] (2) Find from Table 1 that the best detuning degree corresponding to the fastener spacing of 0.625m is 20%, and the best detuning range is -0.135m~0.135m calculated by formula (1.1);

[0060] (3) The length of the rail section where the dynamic resonance unit needs to be installed is 6.25m, that is, 10 dynamic resonance units need to be installed, and a set of detuning quantities are randomly selected from the best detuning range: -0.104m, -0.1m, -0.0995 m, -0.0998m, -0.102m, 0.0964m, 0.097m, 0.0991m, 0.105m, 0.11m, the rail mid-span position between adjacent fasteners is the standard reference position.

[0061] (4) According to the selected detuning amount, move left and right to determine the installation position of the resonance unit, and finally perform one-to-one corresponding installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com