Novel antiknock composite structure of underground engineering

An underground engineering and composite structure technology, applied in underwater structures, hydraulic engineering, infrastructure engineering, etc., can solve the loss of emergency repair value of engineering, the overall collapse of underground engineering structure and surrounding rock, and the failure of explosion-proof structure to restore the material structure. and other problems to achieve the effect of maintaining integrity and restoring structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

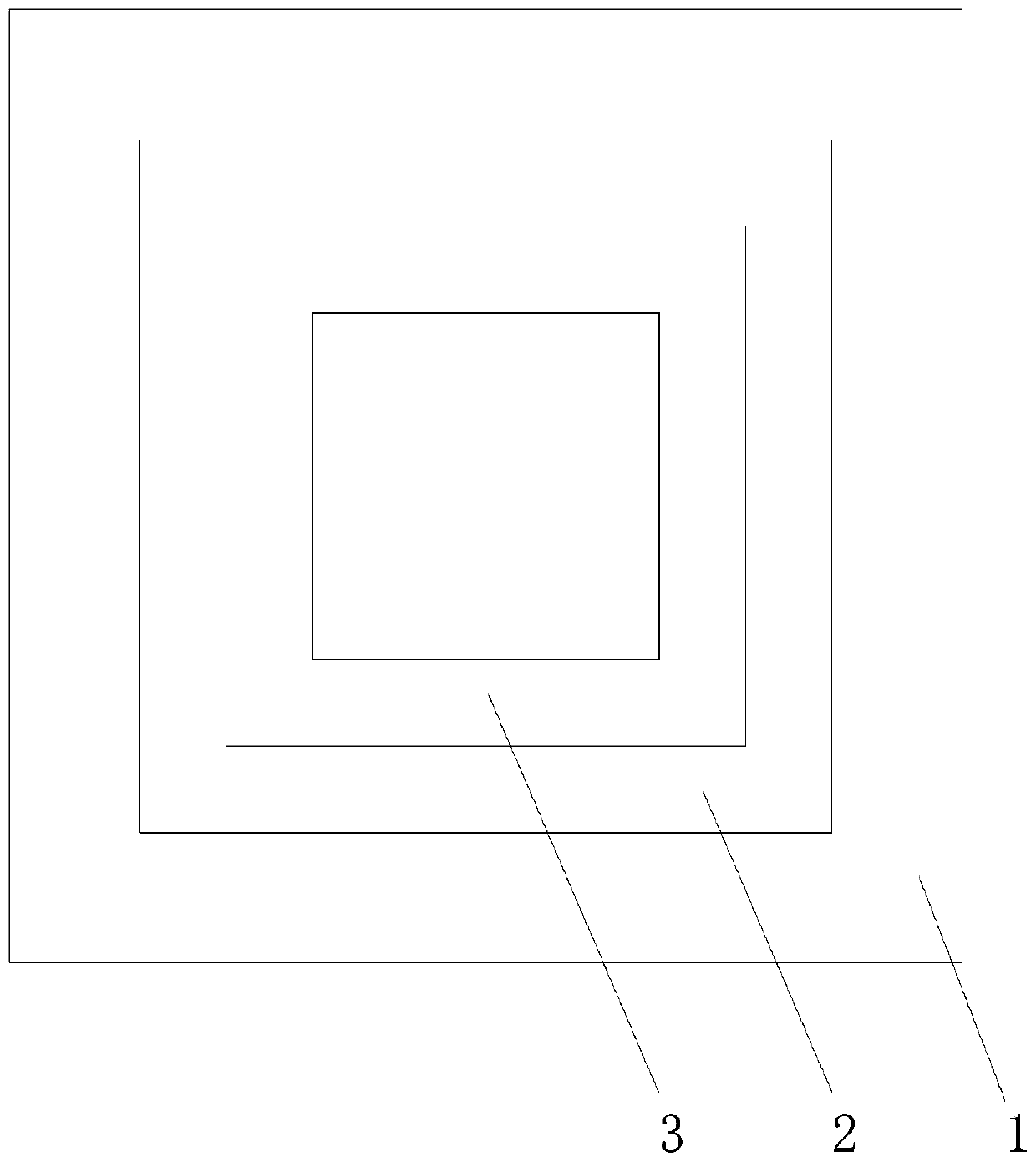

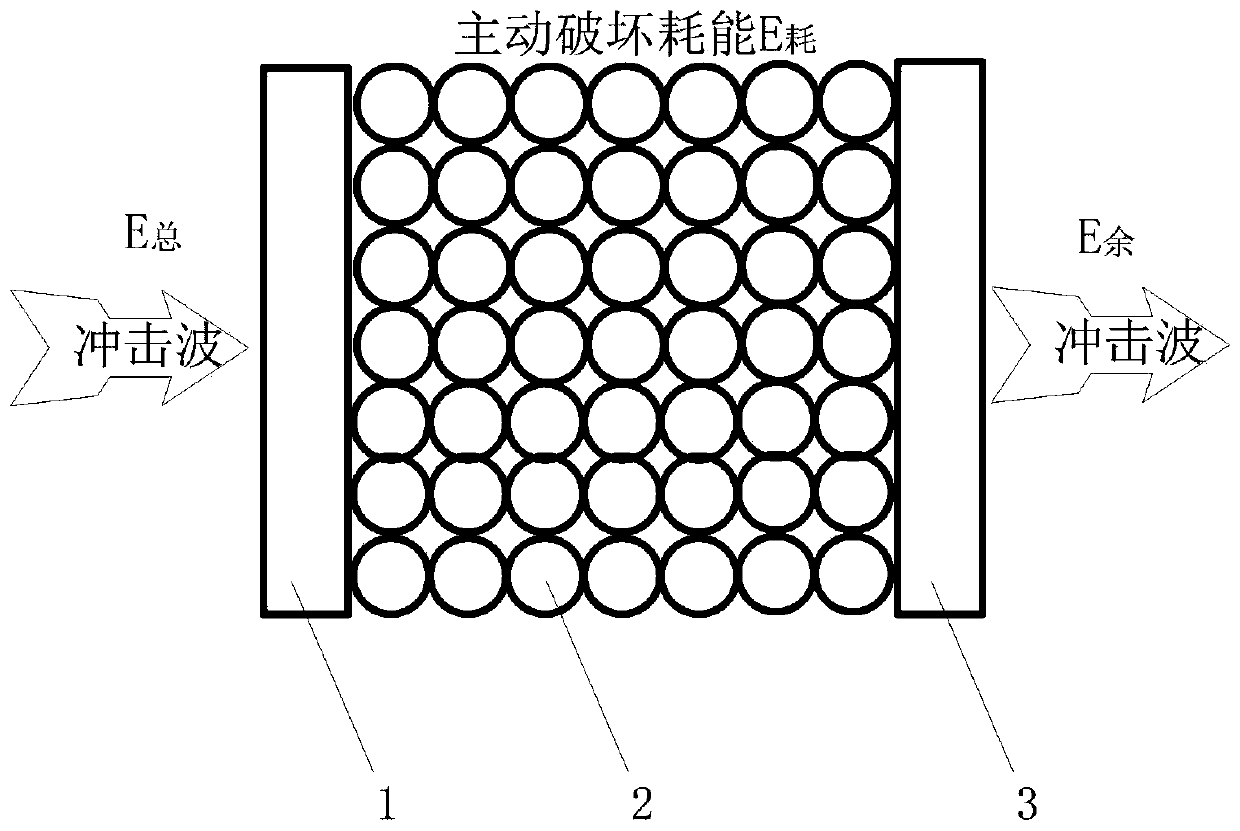

[0015] The invention provides a novel anti-explosion composite structure for underground engineering, see figure 1 and 2 , including: a surrounding rock layer 1, a closed filling layer 2 and a lining layer 3; the closed filling layer 2 is arranged between the surrounding rock layer 1 and the lining layer 3; A strained skeleton porous concrete material; the low strain skeleton porous concrete material is actively destroyed under the impact of an explosion; the lining layer is a reinforced concrete lining structure for underground engineering.

[0016] Further, the low-strain porous concrete material is a high-performance concrete material with equal particle size or a high-strength high-permeability concrete material.

[0017] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com