Combined type building template fixing structure

A technology for building formwork and fixing structure, which is applied in building construction, construction, and on-site preparation of building components. And the phenomenon of bulging, improve practicality, improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

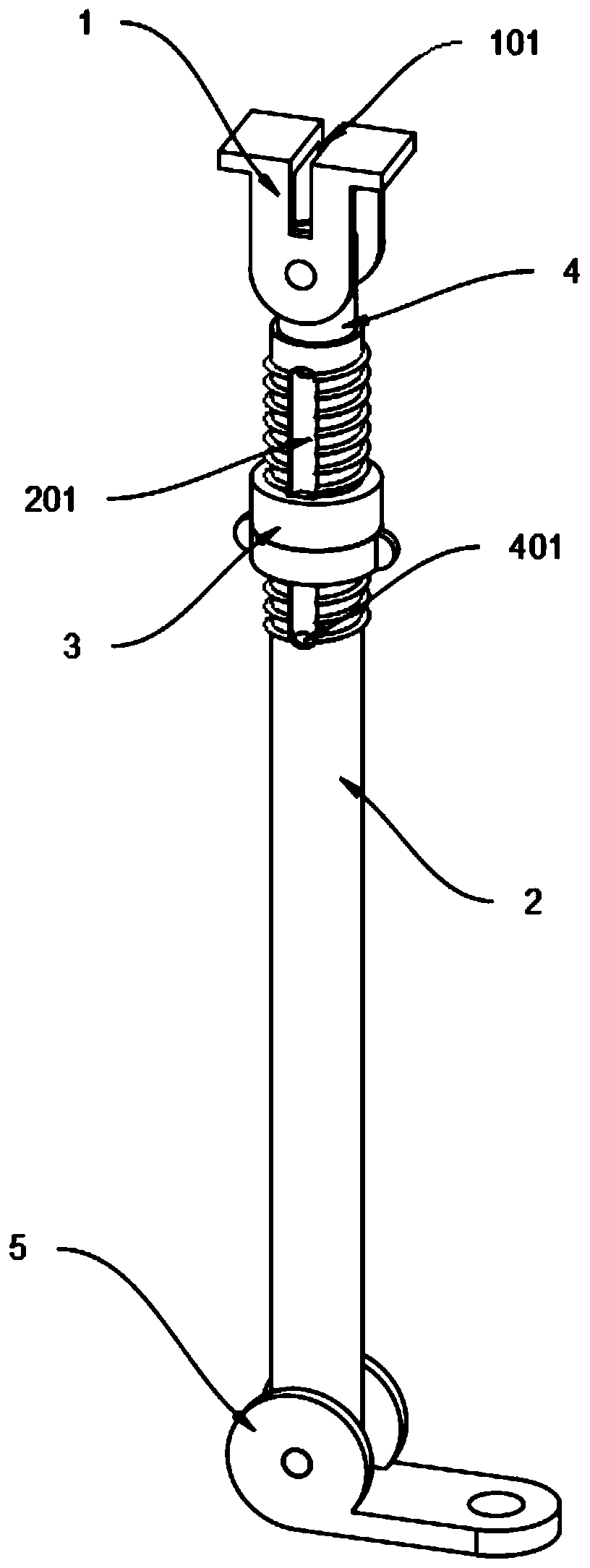

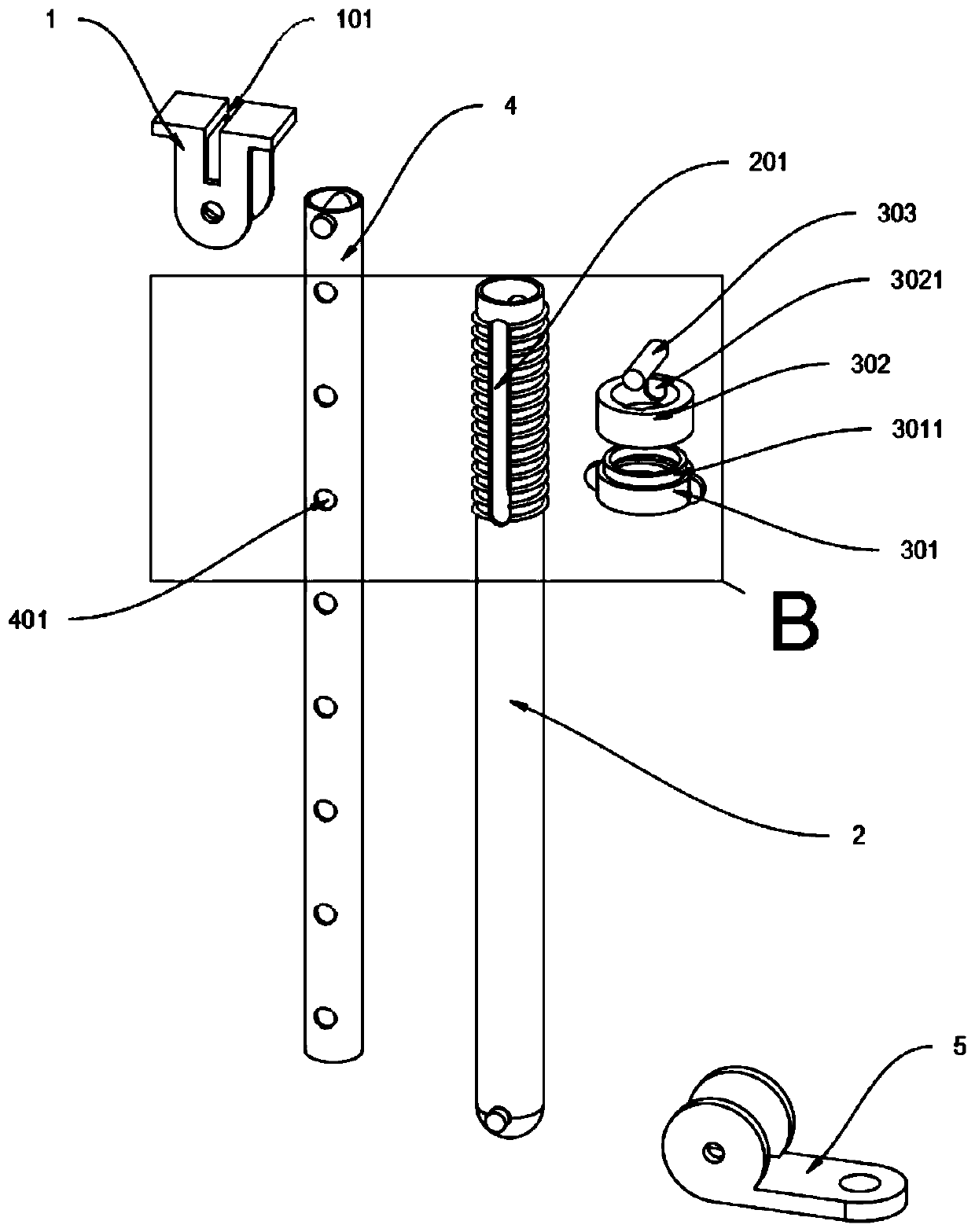

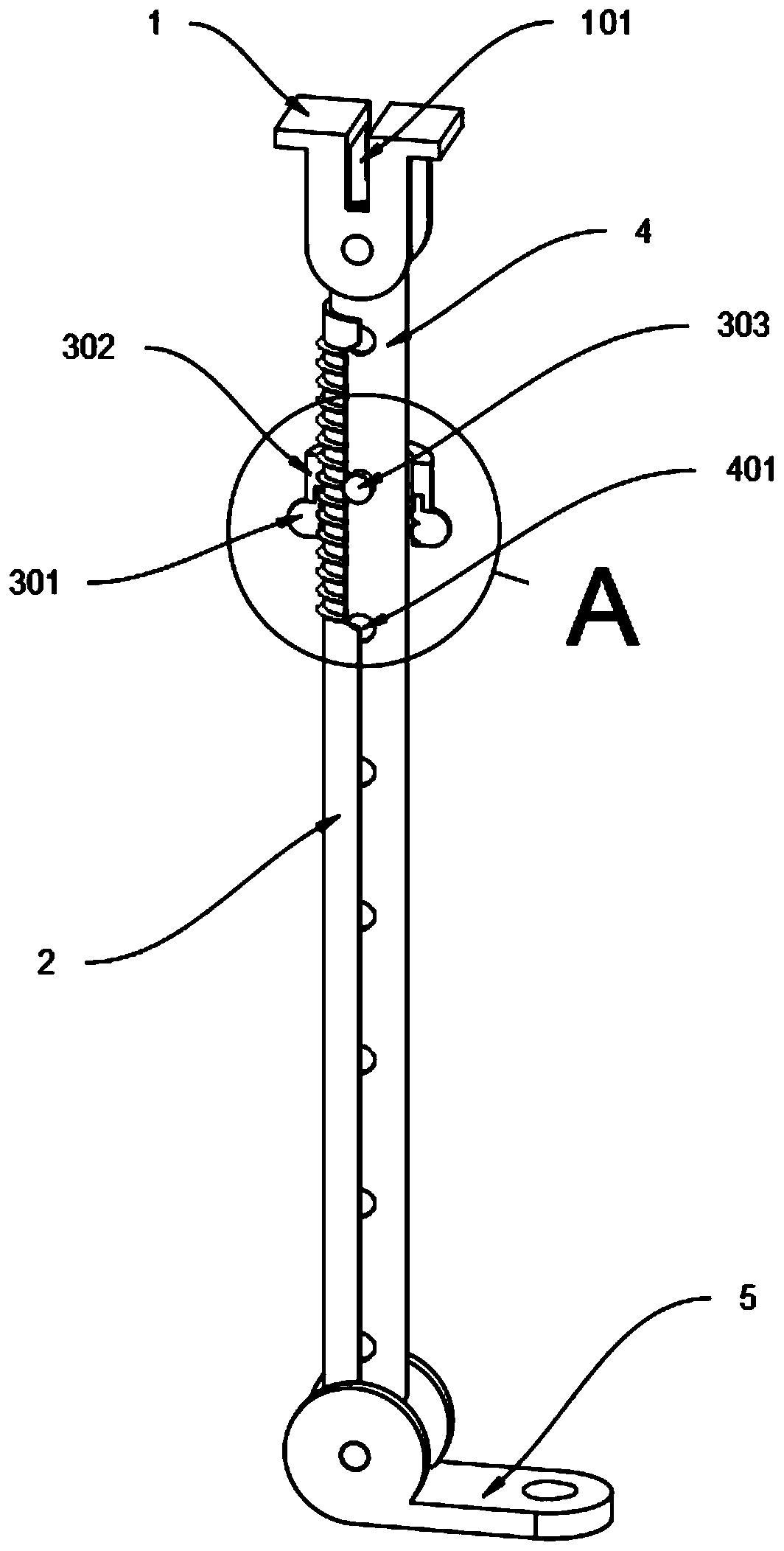

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a combined building formwork fixing structure, including a jacking block 1, an outer fixing tube 2 and a fine-tuning mechanism 3; the jacking block 1 is connected to the top of the inner fixing tube 4 through a pin bar rotation; the outer fixing tube 2 is rotated through a pin bar Connected to the inside of the fixed seat 5; the top pipe body of the outer fixed pipe 2 is provided with a fine-tuning hole 201, and the outside of the fine-tuning hole 201 is provided with threads, as attached figure 2 And attached Figure 8 As shown, this design enables the rotary cylinder 301 to rise or fall under the action of the thread when rotating, and the positioning rod 303 is pushed by the rotary cylinder 302 to drive the internal fixing tube 4 to rise or fall to realize the tight fixing of the template, which further improves the device. flexibility; the length of the outer thread of the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap