Method for safe passage of box 7 brown mudstone section in sulige side tracking slim hole

A tan, mudstone technology, used in drilling equipment and methods, directional drilling, drilling equipment, etc., can solve the problems of mudstone collapse and debris sinking and accumulation, and enhance wellbore stability, increase lubricity, and carry sand. performance, the effect of reducing the risk of downhole accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

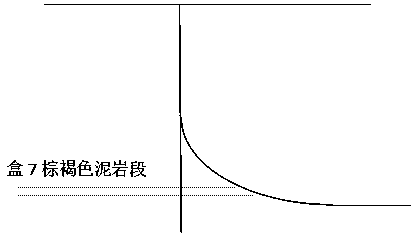

[0031] In order to overcome the problems of existing mudstone collapse and cuttings subsidence and accumulation, the present invention provides such as Figure 1-4 A Sulige sidetracking slim hole box 7 safe crossing method for the tan mudstone section is shown, the invention adjusts the well deviation of the mudstone section from 76°-78° to 68°-70°, and improves the combined righting of the drilling tool The structural characteristics of the drill can solve the problems of mudstone collapse and cuttings subsidence and accumulation from two aspects of the well depth profile and the improvement of the structural characteristics of the drilling tool.

[0032] A method for safely crossing the tan mudstone section of Sulige sidetracking slim hole box 7, characterized in that: the specific steps are:

[0033] Step 1: Adjust the well deviation of the mudstone section from 76°-78° to 68°-70°;

[0034] Step 2, select drill tool assembly and screw rod;

[0035] Step 3: Drill through t...

Embodiment 2

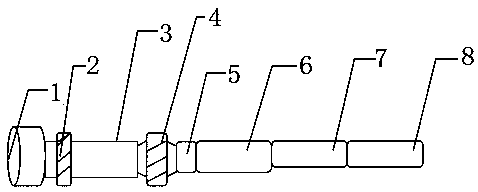

[0041] On the basis of Example 1, in this example, in the step 2, the selected drilling tool assembly is sequentially connected drill bit 1, single-curved screw 3, screw centralizer 2, drilling tool centralizer 4, and directional joint 5. Non-magnetic drill collar 6, slope weighted drill pipe 7 and drill pipe 8.

[0042] The drill bit 1 is a Φ118mm PDC drill bit, the single-curved screw 3 is a Φ95mm 1.25° single-curved screw, the directional joint 5 is a Φ105mm directional joint, the non-magnetic drill collar 6 is a Φ105mm non-magnetic drill collar, and the slope-weighted drill pipe 7 is Φ88.9mm Slope heavy drill pipe, drill pipe 8 is Φ 88.9mm drill pipe.

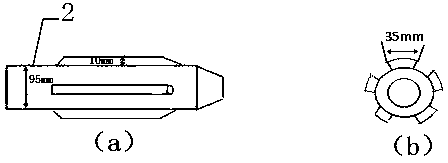

[0043] The drilling tool centralizer 4 is a structure of a straight-edged centralizer with a deep passageway. The outer diameter of the main body of the centralizer is 95mm, the maximum outer diameter of the centralizer is 114mm, the rib height of the centralizer is 15mm, and the rib width is 35mm.

[0044] like Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com