Air inlet assembly of gas engine

A technology of gas engine and air intake components, which is applied in the direction of engine components, combustion engines, fuel air inlets, etc., can solve problems such as potential safety hazards, and achieve high safety, improved sealing, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

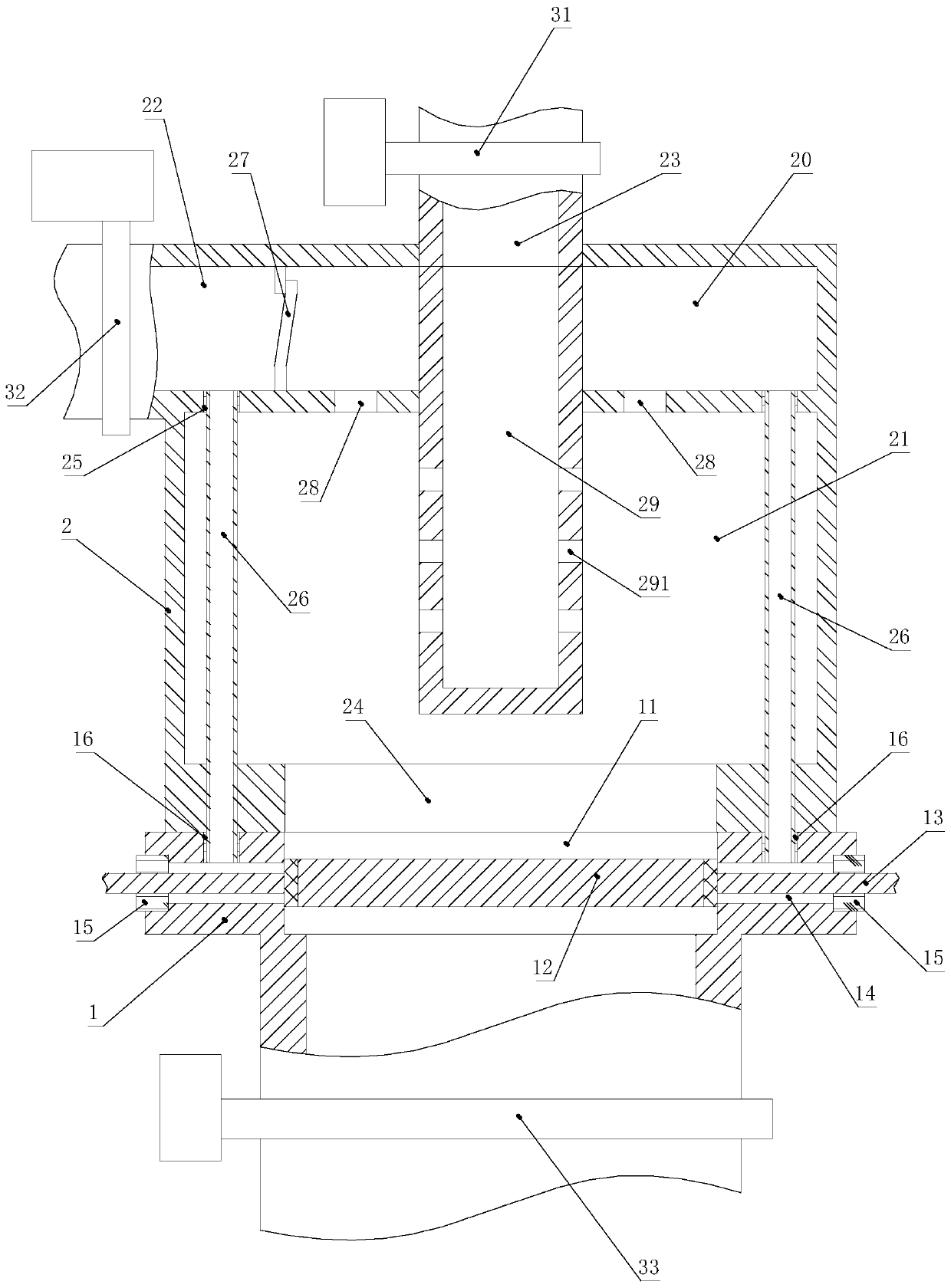

[0026] A gas engine intake assembly includes a throttle valve 1. Specifically, the position of the throttle valve 1 in the gas engine intake system and the connection relationship with other components are the same as those of the existing gas engine intake system. The throttle valve 1 includes a vent 11 and a valve plate 12, the valve plate 12 is provided with a rotating shaft 13, the side wall of the vent hole 11 is provided with two rotating shaft holes 14, and both ends of the rotating shaft 13 are respectively inserted in the rotating shaft holes In 14, a mechanical sealing device 15 is provided at the outer end of the shaft hole 14. Similar to the existing throttle valve, the opening size of the vent hole 11 of the throttle valve 1 is controlled by the rotation angle of the valve plate 12 to control the flow rate of the mixed gas entering the combustion chamber of the gas engine. The difference is that the hole wall of the shaft hole 14 of the throttle valve 1 is provided...

Embodiment 2

[0033] Based on Example 1, the compressed air inlet 22 is provided with a one-way valve 27, and the one-way valve 27 is located between the second inlet 16 and the outlet end of the compressed air inlet 22 to prevent the mixer Gas backflow in 2.

[0034] Preferably, the inlet end of the gas inlet 23 is connected to a first meter 31, which is used to monitor the amount of gas entering the mixer 2; the inlet end of the compressed air inlet 22 is connected to There is a second meter 32, the second meter 32 is used to monitor the amount of air entering the mixer 2; the mixed gas outlet 24 is connected to a third meter 33, the third meter 33 is used to monitor the mixer 2 The amount of gas entering the combustion chamber of a gas engine.

[0035] By comparing the sum of the readings of the first meter 31 and the second meter 32 with the reading of the third meter 33, it can be judged whether the gas engine intake system is leaking, and the gas engine intake system can be overhauled in ...

Embodiment 3

[0037] On the basis of Embodiment 1 or Embodiment 2, the mixer 2 further includes a compressed air inlet chamber 20, which communicates with the mixing chamber 21 through a number of connecting holes 28, so that the compressed air and The gas is evenly mixed.

[0038] Preferably, the compressed air inlet cavity 20 and the mixing cavity 21 are both cylindrical shaped cavities. The connecting holes 28 are evenly distributed along the circumferential direction of the axis of the mixing chamber 21 to further improve the uniformity of the mixing of compressed air and fuel gas.

[0039] Preferably, a gas inlet pipe 29 is provided in the middle of the compressed air inlet cavity 20. One end of the gas inlet pipe 29 is in communication with the gas inlet port 23, and the other end of the gas inlet pipe 29 is located in the mixing chamber 21. One end of the gas introduction pipe 29 located in the mixing chamber 21 is closed, and the side wall of the gas introduction pipe 29 located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com