Three-way valve structure

A three-way valve and valve body technology, applied in the field of wall-hung boilers, can solve the problems of shortened service life of the piston, difficult to grasp the error, and loose assembly, etc., and achieve the effects of easy adjustment, long service life and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

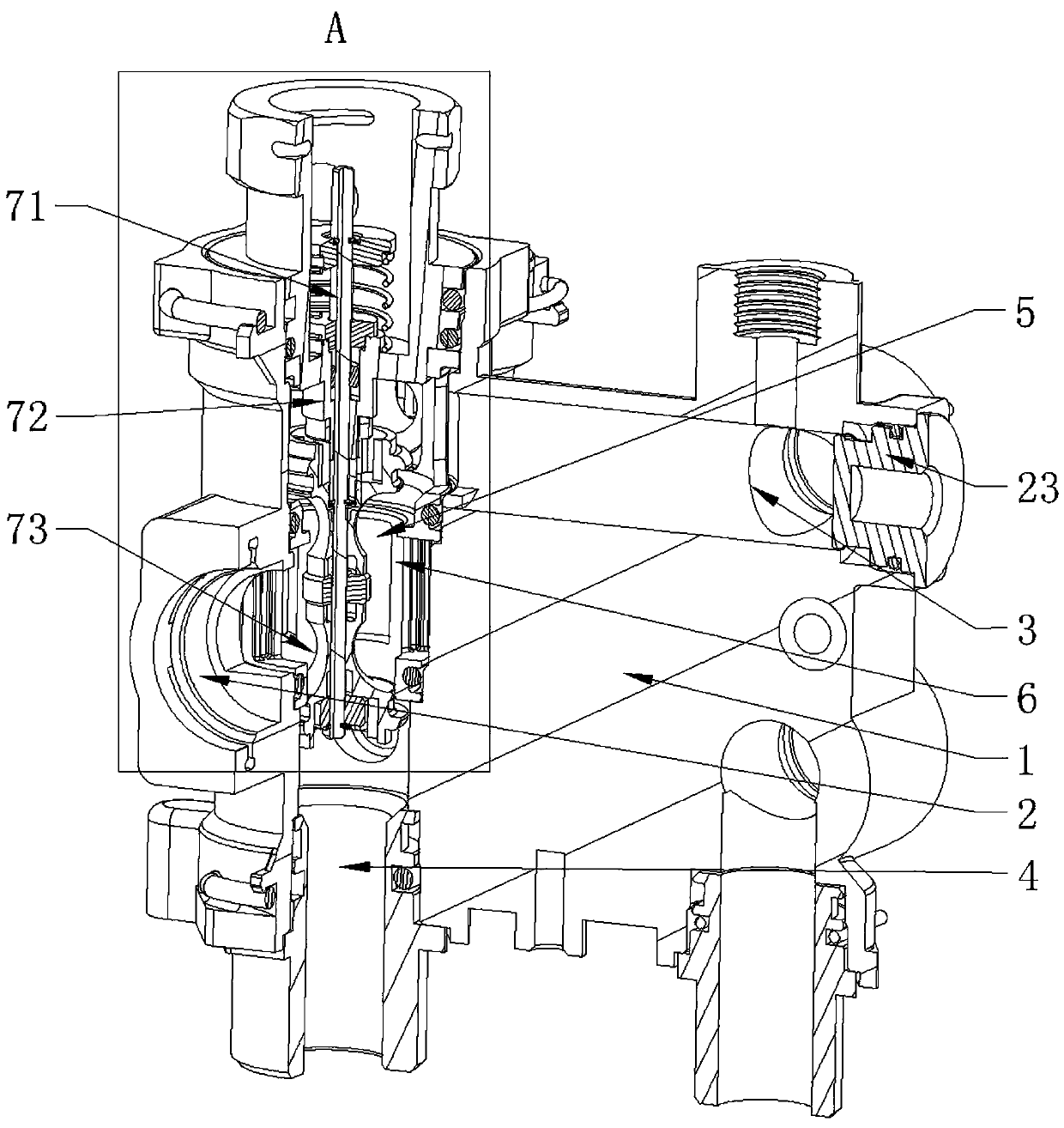

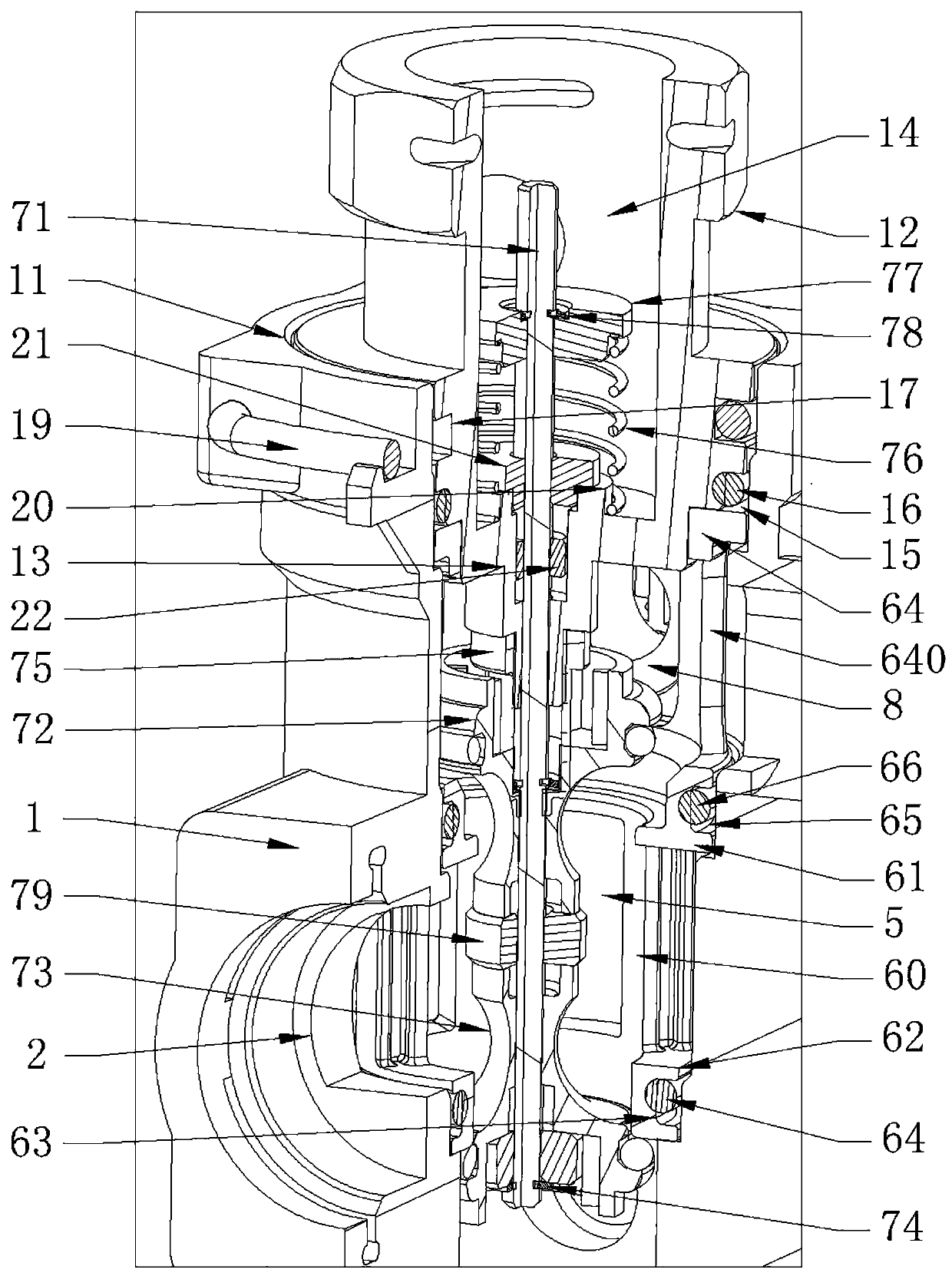

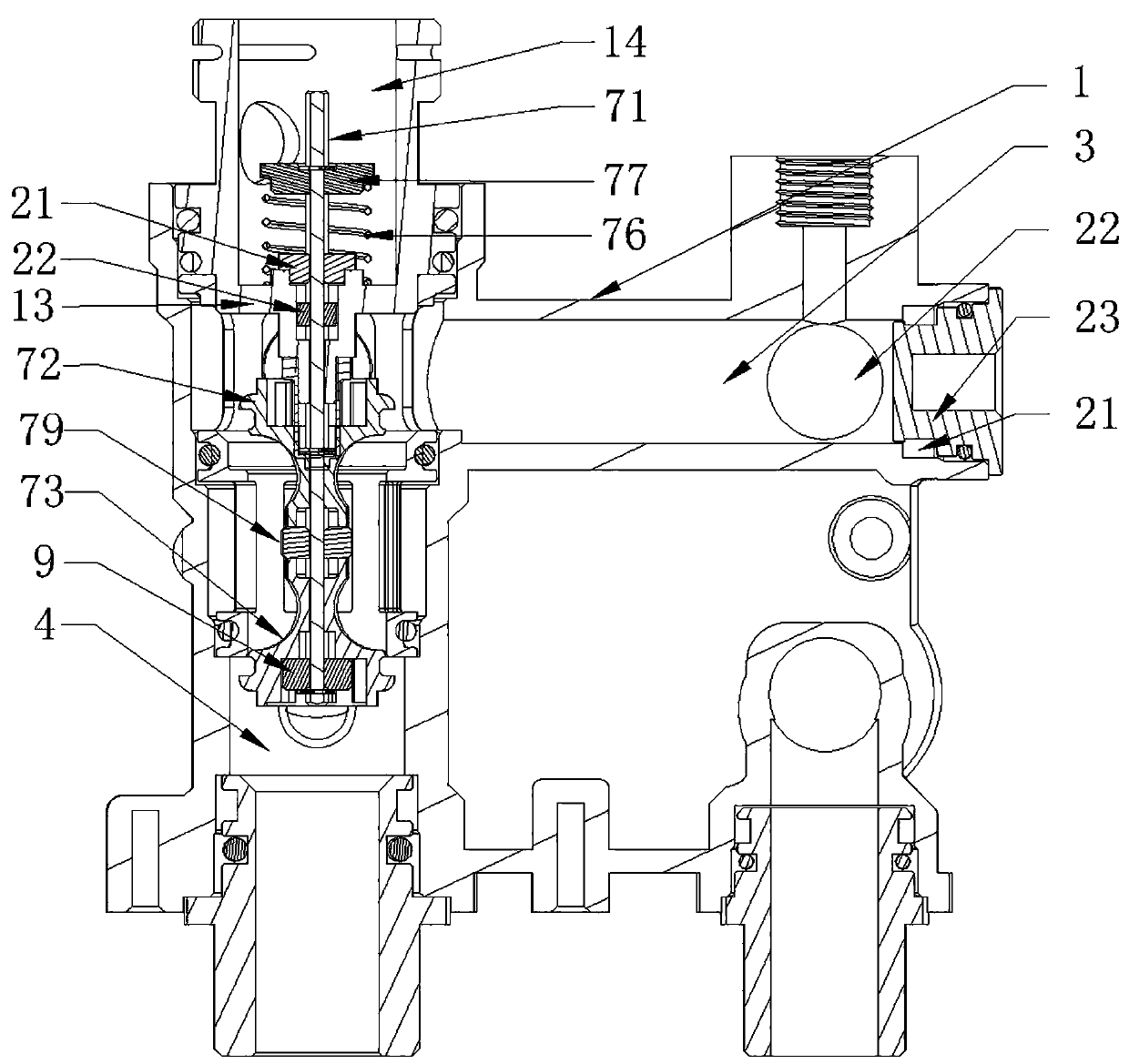

[0024] Such as Figure 1 to Figure 8As shown, in this embodiment, the present invention includes a valve body 1, and the valve body 1 is provided with a water inlet 2, a water outlet 3, a water outlet 2 4, a cavity 5 and a sealing frame 6, and the water outlet One 3 communicates with the upper port of the cavity 5, the water outlet 2 4 communicates with the lower port of the cavity 5, the water inlet 2 communicates with the side port of the cavity 5, and the sealing frame 6 includes an upper seal ring 61 adapted to the upper port of the cavity 5 and a lower seal ring 62 adapted to the lower port of the cavity 5, the upper seal ring 61 is connected to the The lower seal ring 62 is connected, the seal frame 6 is embedded in the cavity 5, and the valve body 1 is provided with a stretching assembly, the stretching assembly includes a drive shaft 71, and the drive shaft 71 The lower end passes through the sealing frame 6 and is provided with an upper piston 72 and a lower piston 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com