Monitoring and grading control method of pipeline thermal insulation status based on dynamic envelope method

A technology of dynamic envelope and pipeline thermal insulation, applied in pipeline systems, thermometers with physical/chemical changes, thermometers, etc., can solve the problem that there is no complete system and method, no perfect technical system has been formed, and thermal insulation structure has large heat loss. and other problems, to achieve the effect of improving the utilization rate of renovation funds and the management level of pipeline insulation, high work efficiency and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for monitoring and grading control of pipeline thermal insulation based on the dynamic envelope method of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

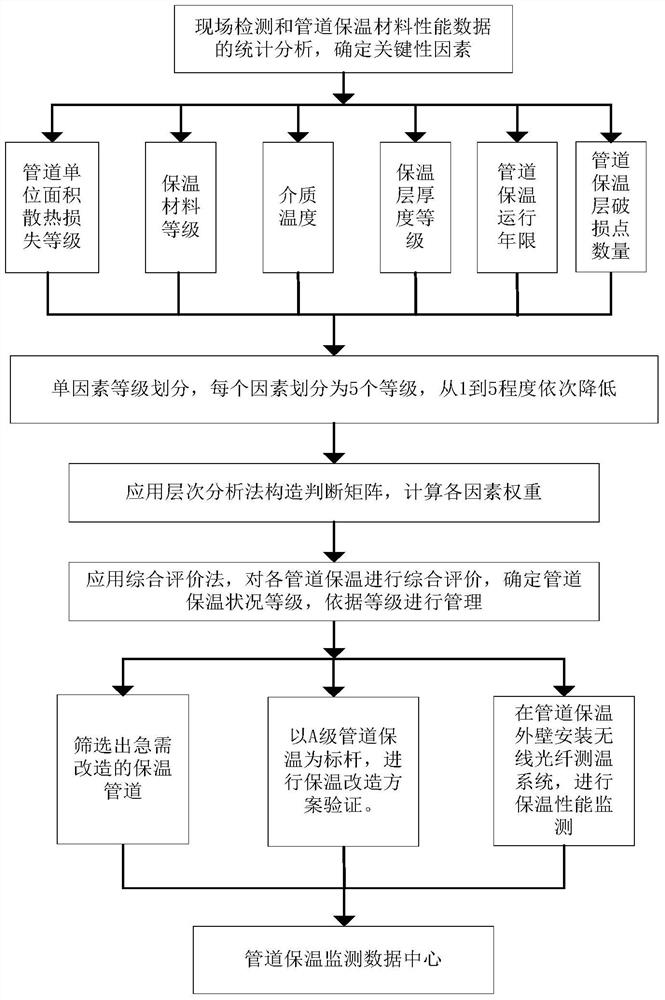

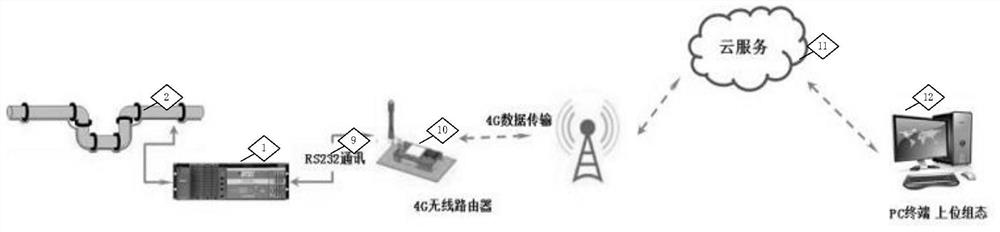

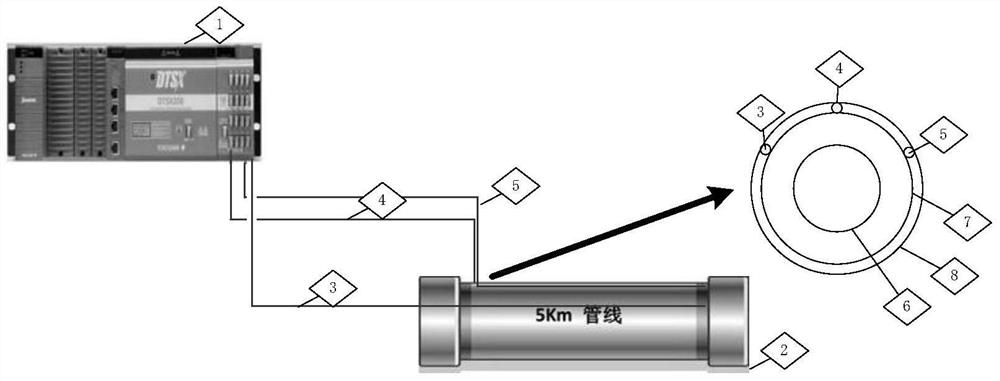

[0022] The pipeline thermal insulation condition monitoring and hierarchical control method based on the dynamic envelope method of the present invention is to use such as figure 1 and figure 2 Shown is the method of pipeline insulation effect classification and real-time monitoring system of operation status. The monitoring results of the operation status of pipeline insulation are mainly affected by two factors, system factors and random factors. During the operation of pipeline insulation, the present invention focuses on the stability and normality of the operation status. If there are Large variable system influence factors or large random influence factors will cause abnormal fluctuations in the average value and standard de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com