High-voltage switch cabinet structure

A high-voltage switchgear and cabinet technology, applied in the field of switchgear, can solve the problems of small space in the bus room B, occupying space, affecting the conductive performance of the busbar copper bars, etc., to achieve the effect of large remaining space and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

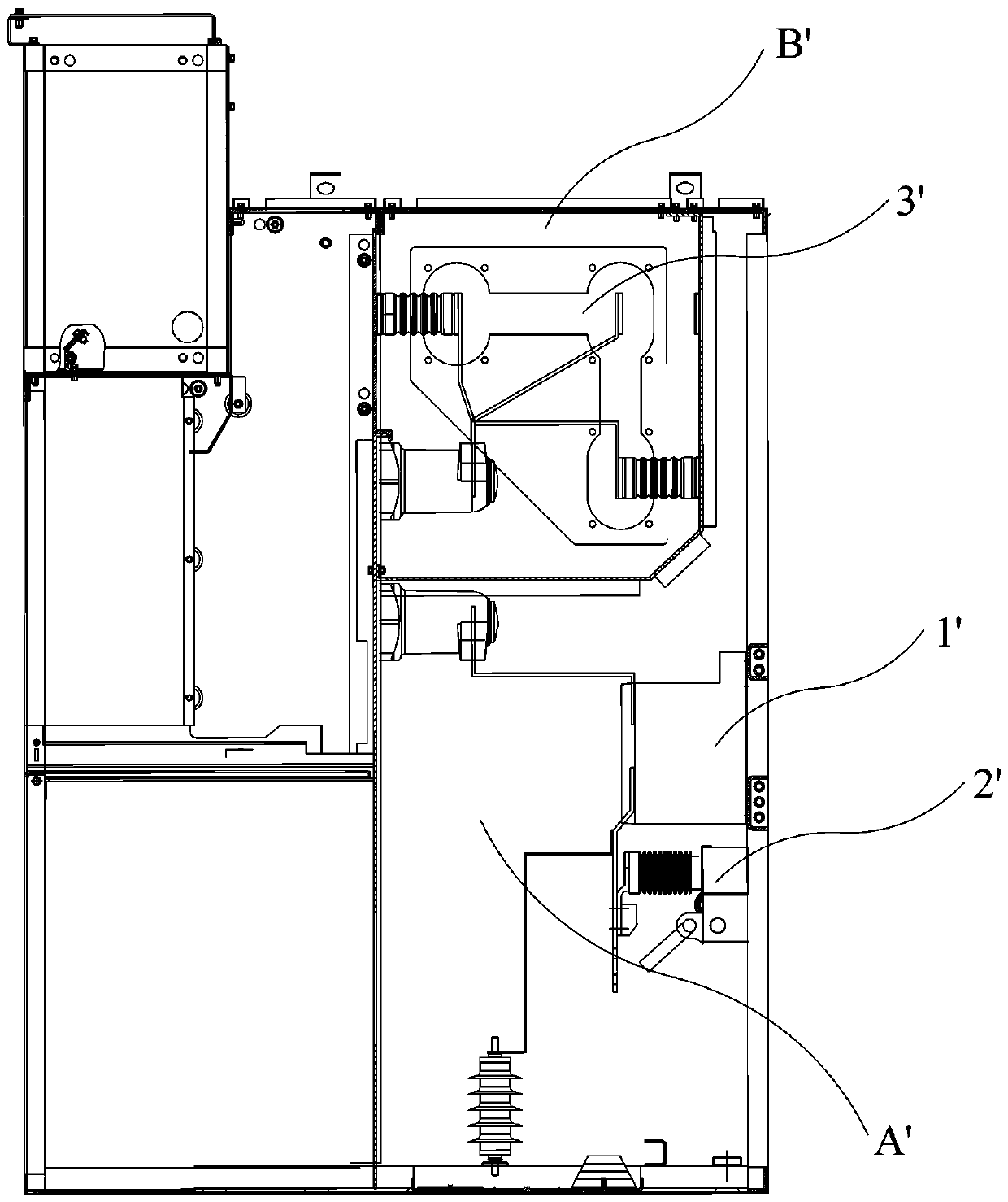

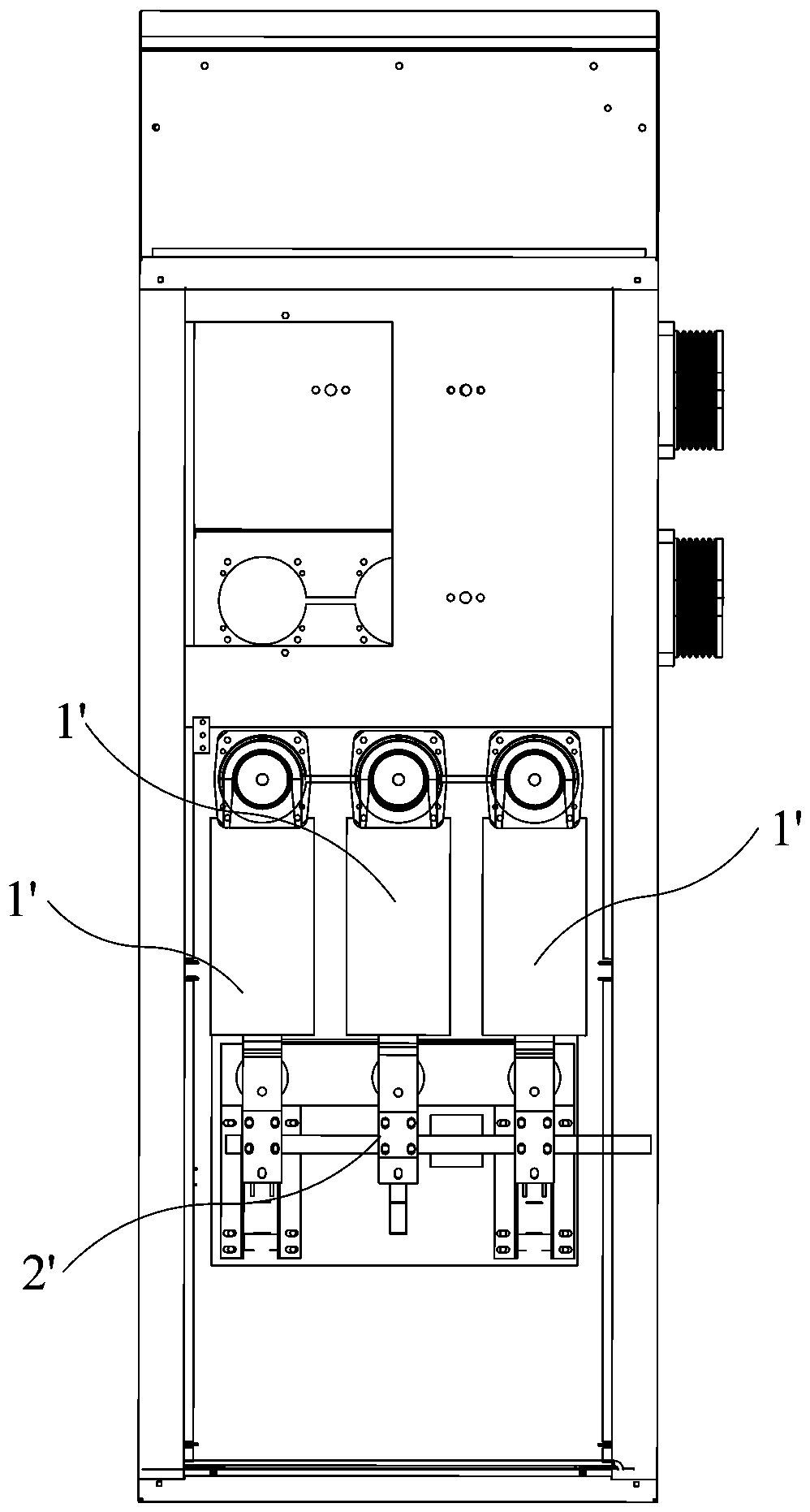

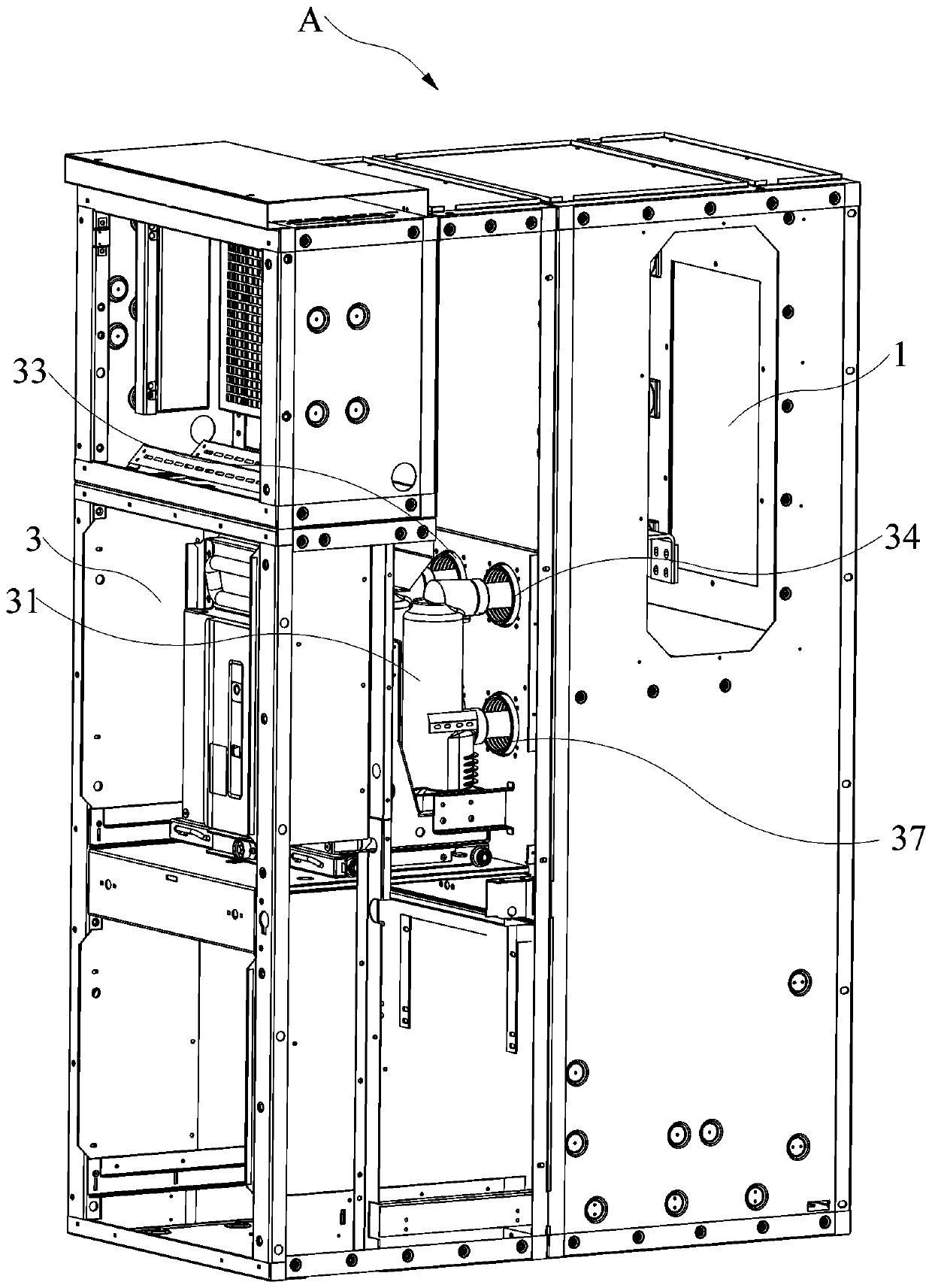

[0039] Such as Figure 3 to Figure 11 As shown, the present invention discloses a high-voltage switchgear structure, which includes a cabinet A, and the cabinet A is provided with a busbar room 1, a cable room 2 and a circuit breaker room 3, wherein the circuit breaker room 3 is located at the front of the cabinet A , the busbar room 1 and the cable room 2 are located at the rear of the cabinet A and the cable room 2 is below the busbar room 1, the circuit breaker room 3 is separated from the busbar room 1 and the cable room 2 by a safety partition 4, and the busbar room 1 is separated by a bend The plate 5 is separated from the cable chamber 2. The bent plate 5 is in an L-shaped structure. The bent plate 5 includes a connected horizontal plate 51 and a vertical plate 52. The horizontal plate 51 and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com