A method for improving the anti-seismic performance of power nickel-metal hydride batteries

A technology of nickel-hydrogen battery and anti-vibration performance, applied in the direction of nickel storage battery, battery electrode, secondary battery, etc., can solve problems such as battery failure, and achieve the effect of preventing short circuit, avoiding potential safety hazards, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Low-capacity power battery D model

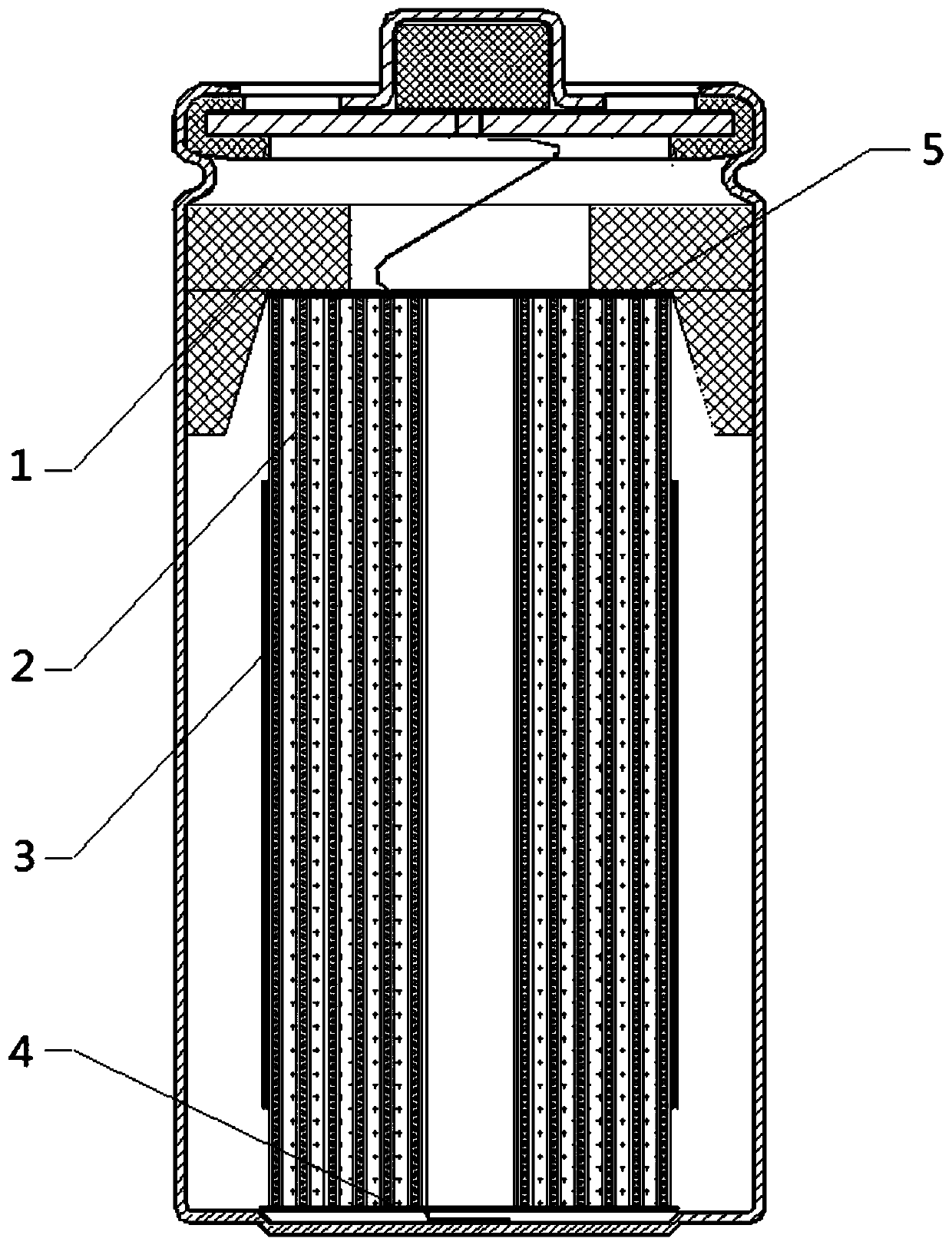

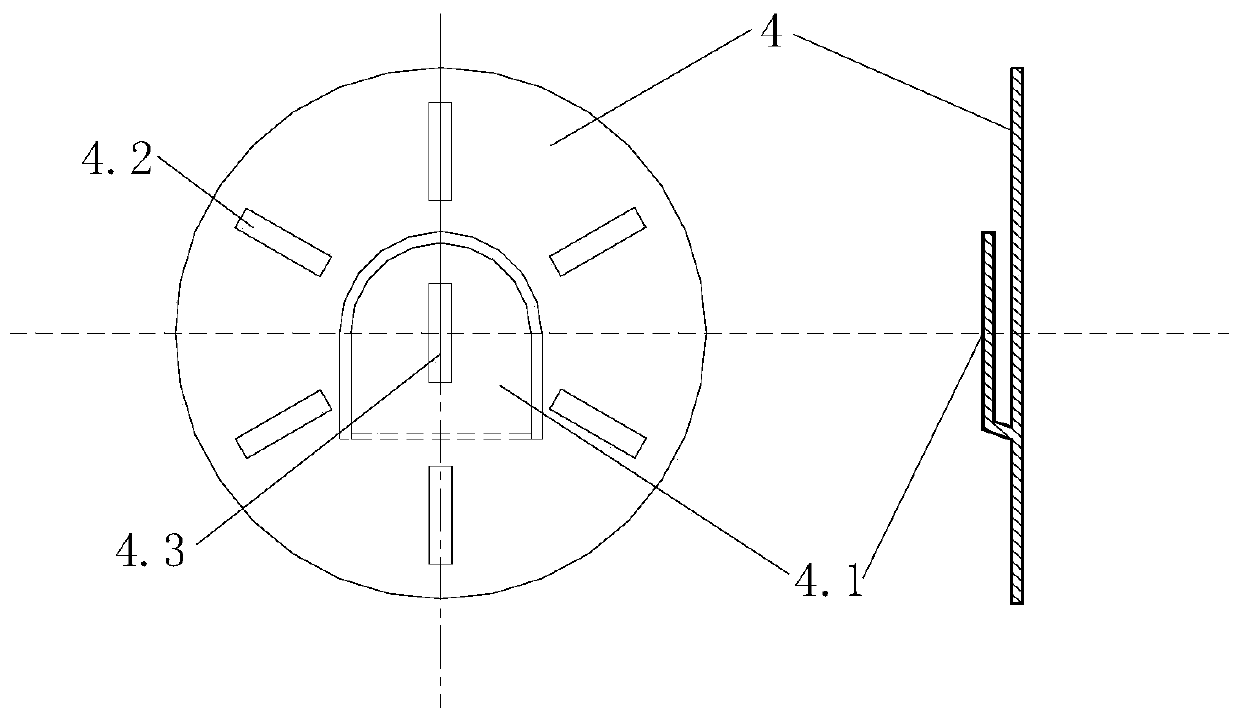

[0045] Such as figure 1 As shown, the low-capacity power battery type D and the capacity of 3.0Ah battery are taken as an example to implement the description. Adopt the method of the present invention to improve the anti-seismic performance of power type nickel-metal hydride battery, its preparation method is as follows:

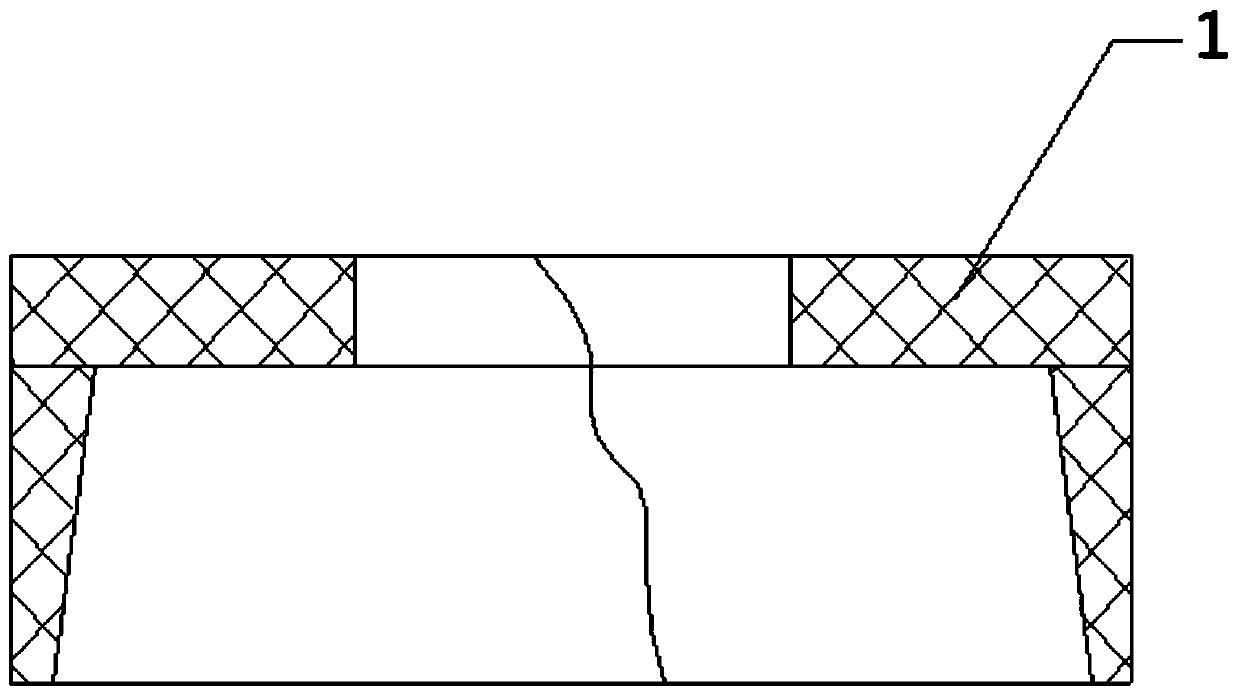

[0046] 1) Fabrication of battery high-strength positive plate 2

[0047] To produce a D-type power battery with a capacity of 3.0Ah, the weight of the positive electrode powder is designed to be 12g, and the size of the positive electrode is designed to be 150mmx50mmx0.595mm.

[0048] Selection of positive electrode binder: use compound CMC binder. Specifically: choose 1% concentration of low viscosity (viscosity is 300-400mpa.s) CMC (preferred model is WS-C), 1% concentration of high viscosity (viscosity is 2000-2200mpa.s) CMC (preferred model is 2200 ); wherein, 1% concentration of low-viscosity...

Embodiment 2

[0072] Example 2 Battery Vibration Test

[0073] Fully charge the battery of Example 1 after welding cap-liquid injection-sealing-formation-aging-activation-sorting. Test the fully charged battery according to the test method of the vibration performance of the battery in the national standard IEC62133 "Safety Requirements for Portable Sealed Secondary Single Batteries and Batteries Made of Them Used in Portable Devices", and measure 20 batteries after the test Battery voltage, internal resistance, observe the appearance and dissect the battery.

[0074] After testing the batteries produced in the examples, it was found that the voltage and internal resistance of the batteries did not change before and after the test, and the cells inside the batteries did not shake. After dissecting 5 batteries, it was found that there was no accumulation of positive electrode powder on the bottom of the cells and on the upper part of the negative current collector. There is no powder fallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com