Method for improving properties of separator through post-treatment crosslinking and separator thereby

A technology of physical properties and separators, which is applied to structural parts, battery pack components, electrical components, etc., can solve problems such as the physical properties of separators that have not yet been proposed, and achieve the effect of improving insulation and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0094] Hereinafter, the present invention will be described in detail with reference to the following examples and test examples; however, the present invention is not limited by these examples and test examples. The embodiments can be modified into various other forms, and the scope of the present invention should not be construed as being limited by the embodiments that will be described in detail. These embodiments are provided to explain the present invention more fully to those of ordinary skill in the art to which the present invention belongs.

[0095]

[0096] (Manufacture of partitions 1 and 2)

[0097] For experimental purposes, two already produced separators, CSP gen1 (separator 1) and BA1_B09PA1 (separator 2) were used. CSP gen1 separator only made of alumina Al 2 O 3 Made of granules and PVDF binder. The BA1_B09PA1 separator has a polyethylene (polyethylene) substrate including Al 2 O 3 Coating of inorganic particles and PVDF binder.

[0098] Triethylamine (TEA, Trie...

comparative test 1

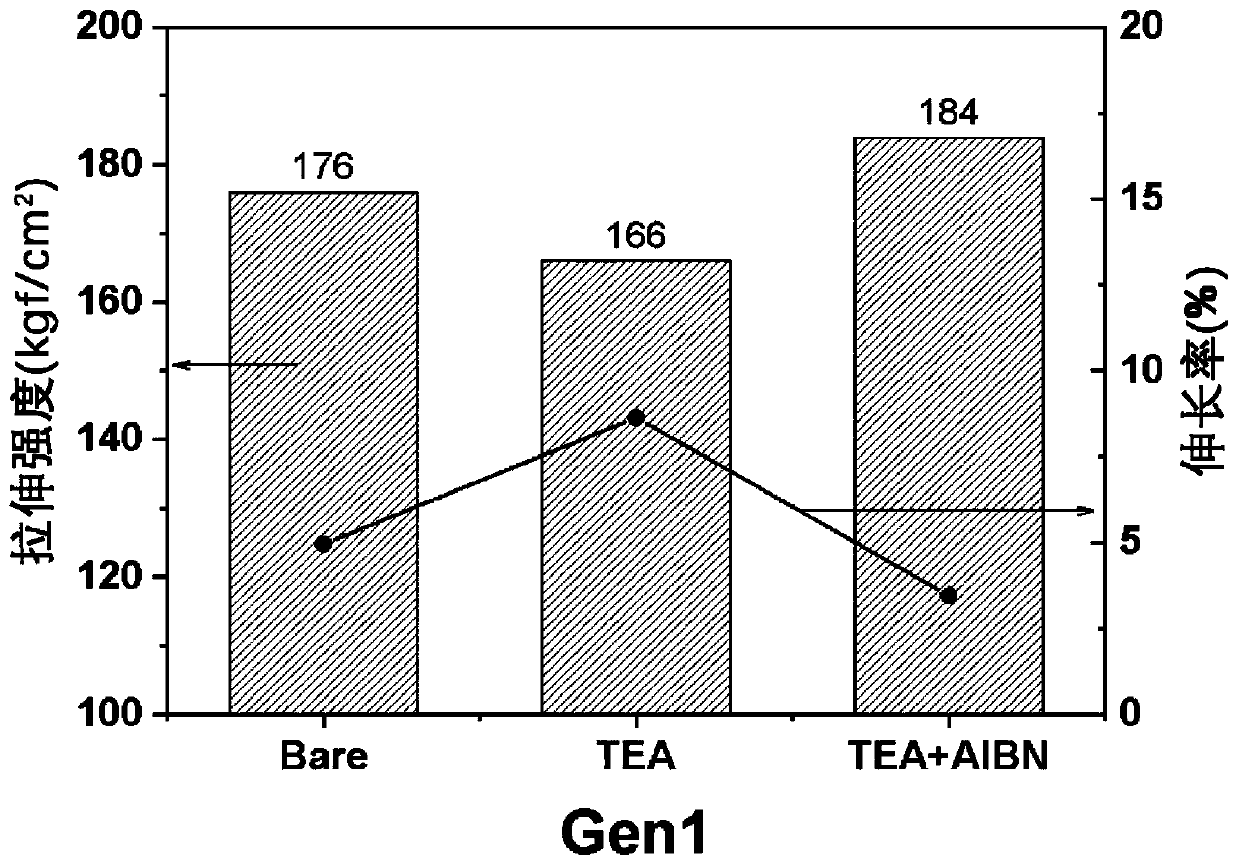

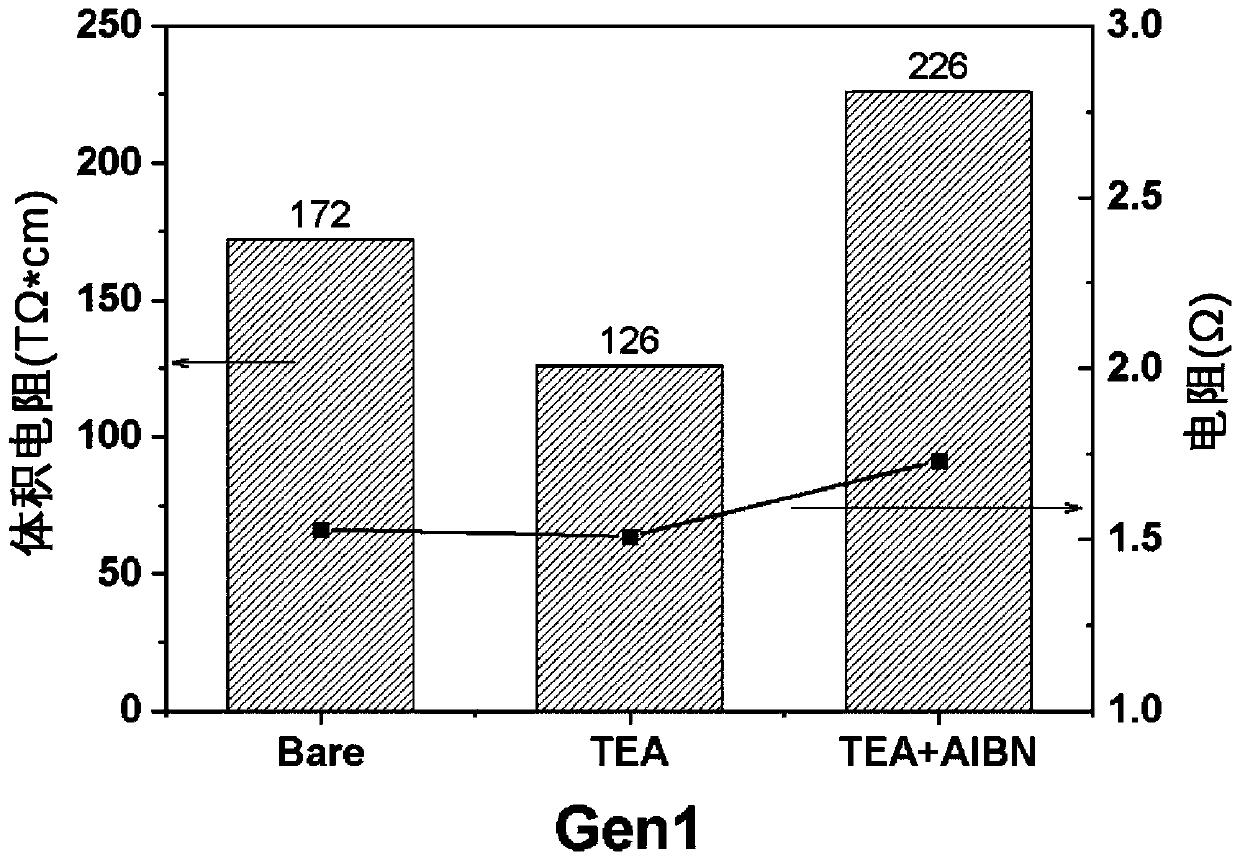

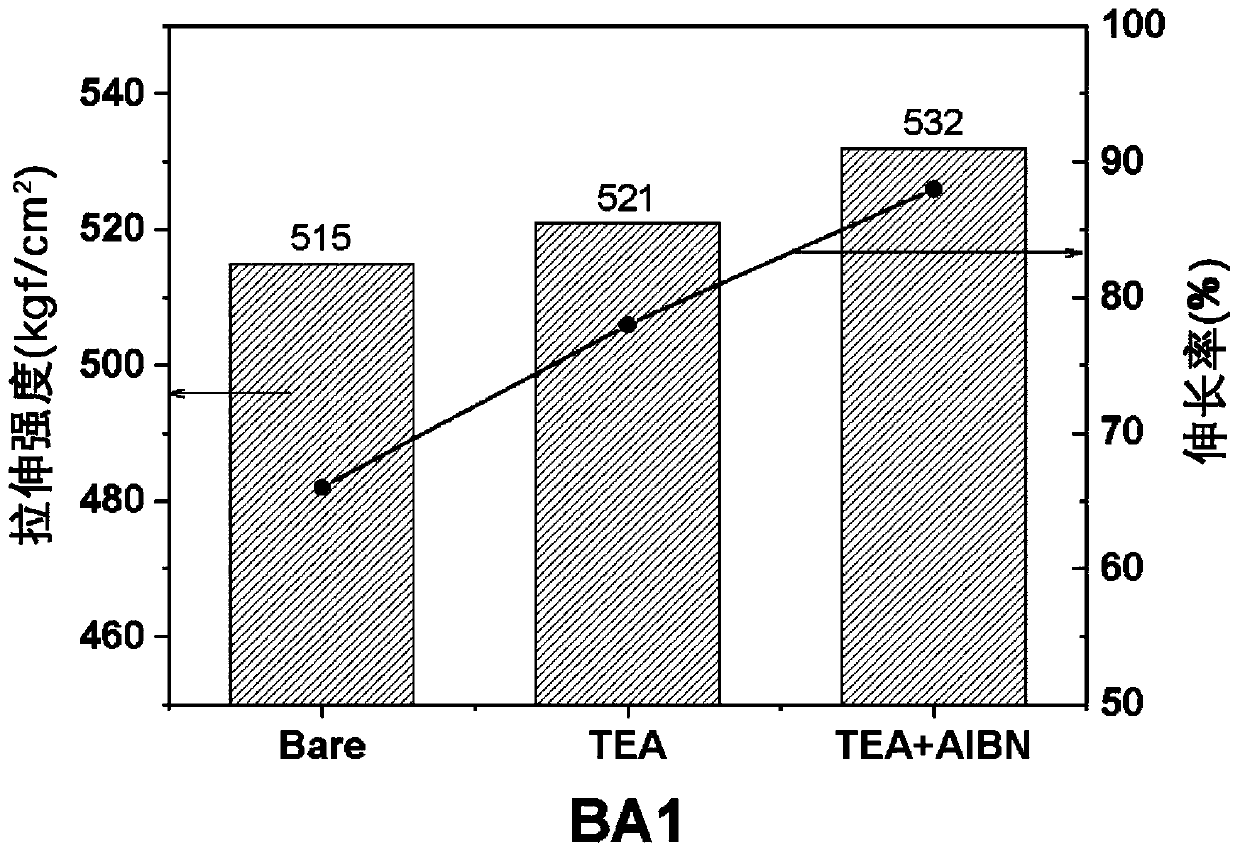

[0101] Comparative Examples 1 and 2 were prepared by not treating the separators 1 and 2. Examples 1 and 2 were prepared by subjecting only the separators 1 and 2 according to the present invention to TEA treatment. Examples 3 and 4 were prepared by subjecting separators 1 and 2 to TEA and AIBN treatments. The tensile strength, elongation, insulation resistance, and electrical resistance of the separators of Comparative Examples 1 and 2, Examples 1 and 2, and Examples 3 and 4 were respectively measured under the following conditions.

[0102]

[0103] Applied voltage: 100V

[0104] Measuring time: 3S

[0105] The size and shape of the electrode: 19.6cm 2 Round

[0106]

[0107] The width of the partition: 2cm

[0108] Stretching speed: 500mm / min

[0109]

[0110] Figure 1 to Figure 4 The measurement results of the physical properties of Comparative Examples 1 and 2 and Examples 1, 2, 3, and 4 according to the present invention are shown, respectively. In the Gen1 separator, Bare is...

comparative test 2

[0113] Al 2 O 3 Before the coating made of inorganic particles and PVDF binder is formed on the separator 2, in the slurry preparation process of the coating material, triethylamine (TEA, Triethylamine) and After cross-linking 2,2'-azobis(isobutyronitrile) (AIBN, 2,2'-azobis (isobutyronitrile)) to prepare a slurry, the slurry was coated on the separator 2 to prepare a comparison Example 3. The separators of Comparative Example 3 and Example 4 treated with triethylamine (TEA) and 2,2'-azobis(isobutyronitrile) (AIBN) were measured under the following conditions, respectively Tensile strength, elongation, insulation resistance and electrical resistance.

[0114]

[0115] Applied voltage: 100V

[0116] Measuring time: 3S

[0117] The size and shape of the electrode: 19.6cm 2 Round

[0118]

[0119] The width of the partition: 1.5cm

[0120] Stretching speed: 500mm / min

[0121]

[0122] Figure 5 with Image 6 The measurement results of the physical properties of Comparative Example 3 (In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com