A sausage enema device that can automatically repeat sausage casings

A technology for coating and sausage enema, which is applied in the field of automatic repeated sausage casing enema device, which can solve the problems of manpower consumption and insufficient tightness of casing meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

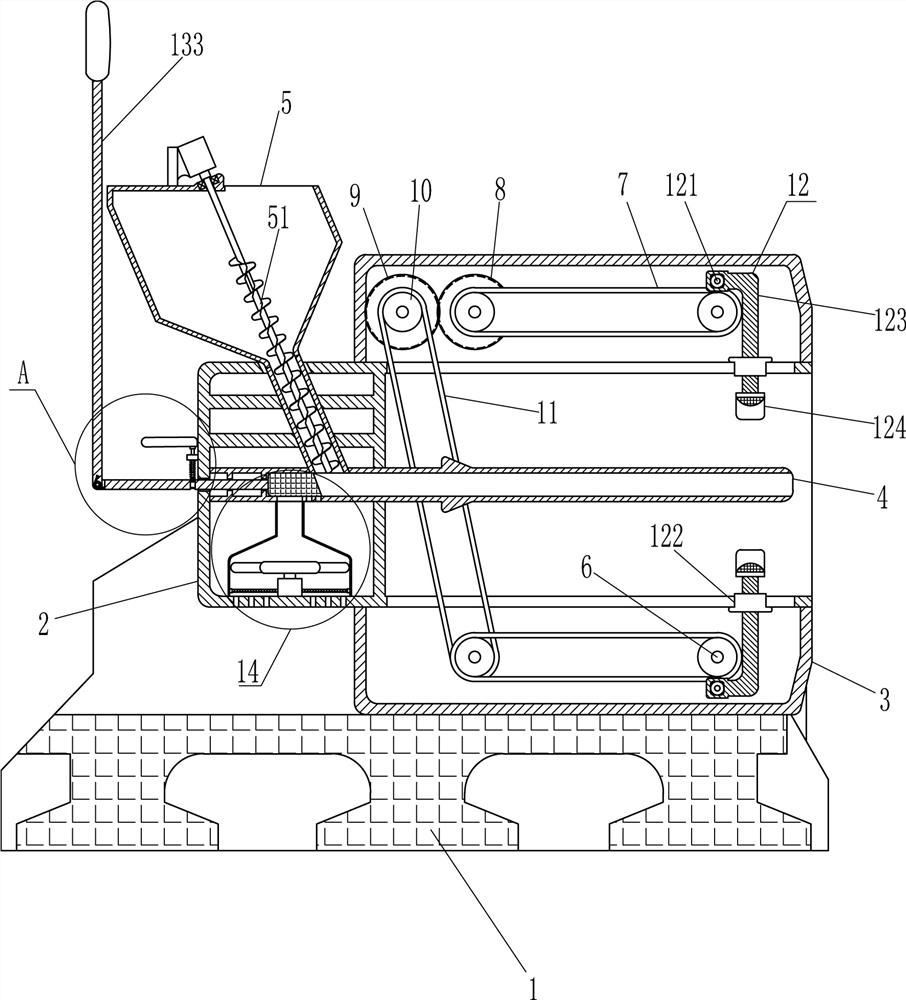

[0017] Such as figure 1 As shown, a sausage enema device that can automatically repeat casings includes a mounting frame 1, a mounting cylinder 2, a first shell 3, a discharge pipe 4, a hopper 5 and a screw conveyor 51, and the middle part of the mounting frame 1 is installed with Installation cylinder 2, the installation cylinder 2 is arranged horizontally, the first housing 3 is connected to the outer top and bottom of the installation cylinder 2, the first housing 3 communicates with the installation cylinder 2, and the middle part of the installation cylinder 2 is set There is a discharge pipe 4. The discharge pipe 4 runs through the center of the installation cylinder 2. A convex ring is provided on the outside of the left part of the discharge pipe 4. Specifically, the convex ring is used to limit the movement of casings. The upper left side of the installation cylinder 2 An inlet hopper 5 is installed, and the inlet hopper 5 is inclined at 50 degrees. The inlet hopper 5...

Embodiment 2

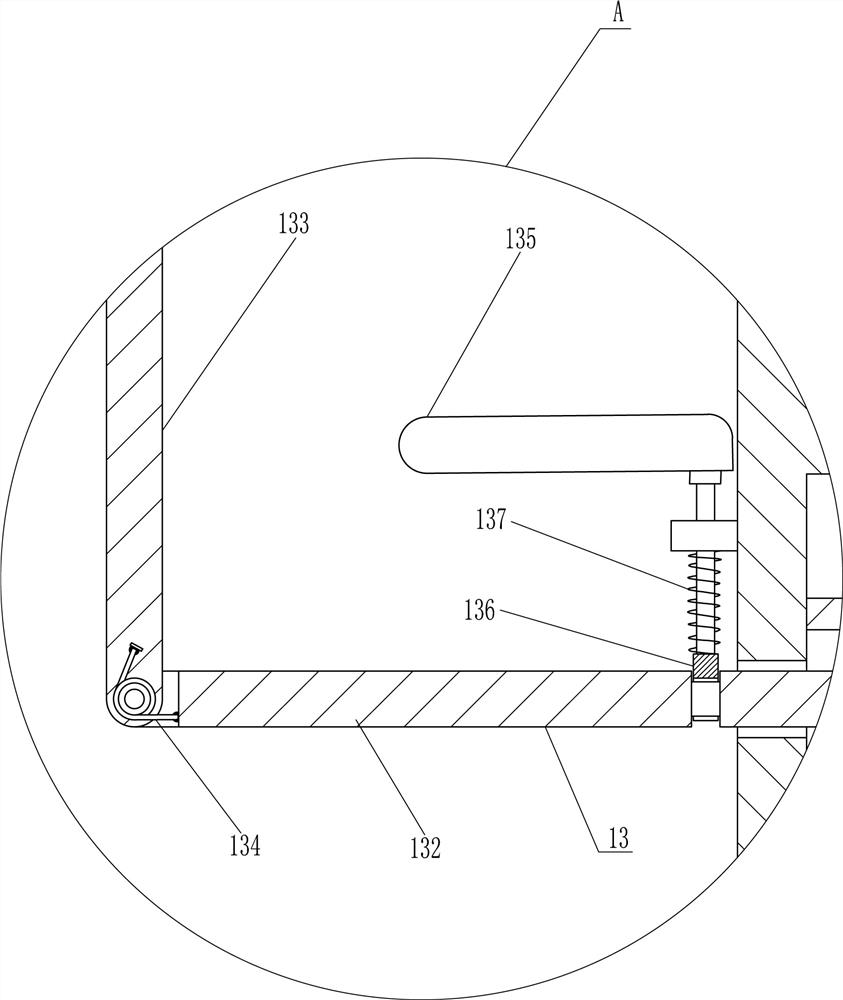

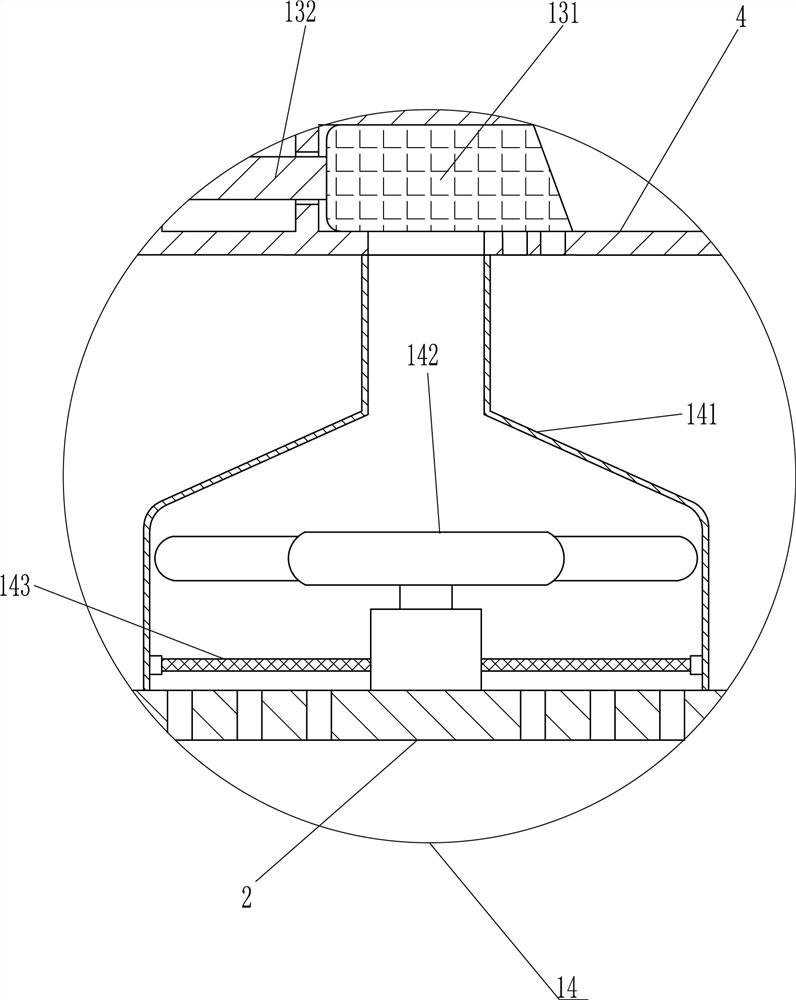

[0022] Such as Figure 2-3 As shown, it also includes a pushing assembly 13, and the pushing assembly 13 includes a piston 131, a push rod 132, a second connecting rod 133, a torsion spring 134, a lifting rod 135, an arc-shaped clamping plate 136 and an elastic member 137. Piston 131 is slidingly arranged in pipe 4, and piston 131 is connected with push rod 132. A torsion spring 134 is connected between the push rod 132, and the second connecting rod 133 is connected to the push rod 132 in an L-shape. A sliding sleeve is arranged above the left wall of the installation cylinder 2, and a lifting rod 135 is slidingly provided in the sliding sleeve to lift up and down. The bottom of the rod 135 is connected with an arc clamp 136, which is located directly above the push rod 132, and the push rod 132 is provided with an annular groove matching the arc clamp 136, and the bottom of the sliding sleeve is connected with the arc clamp. An elastic member 137 is connected between 136 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com