Crushing pair with sieve frame

A technology of screen frame and crushing cavity, applied in the field of mining machinery, can solve the problems of large floor space, increased manufacturing cost, operating cost and self-consumption power, complex crushing production line, etc., to achieve small floor space and improve screening effect. , the effect of simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

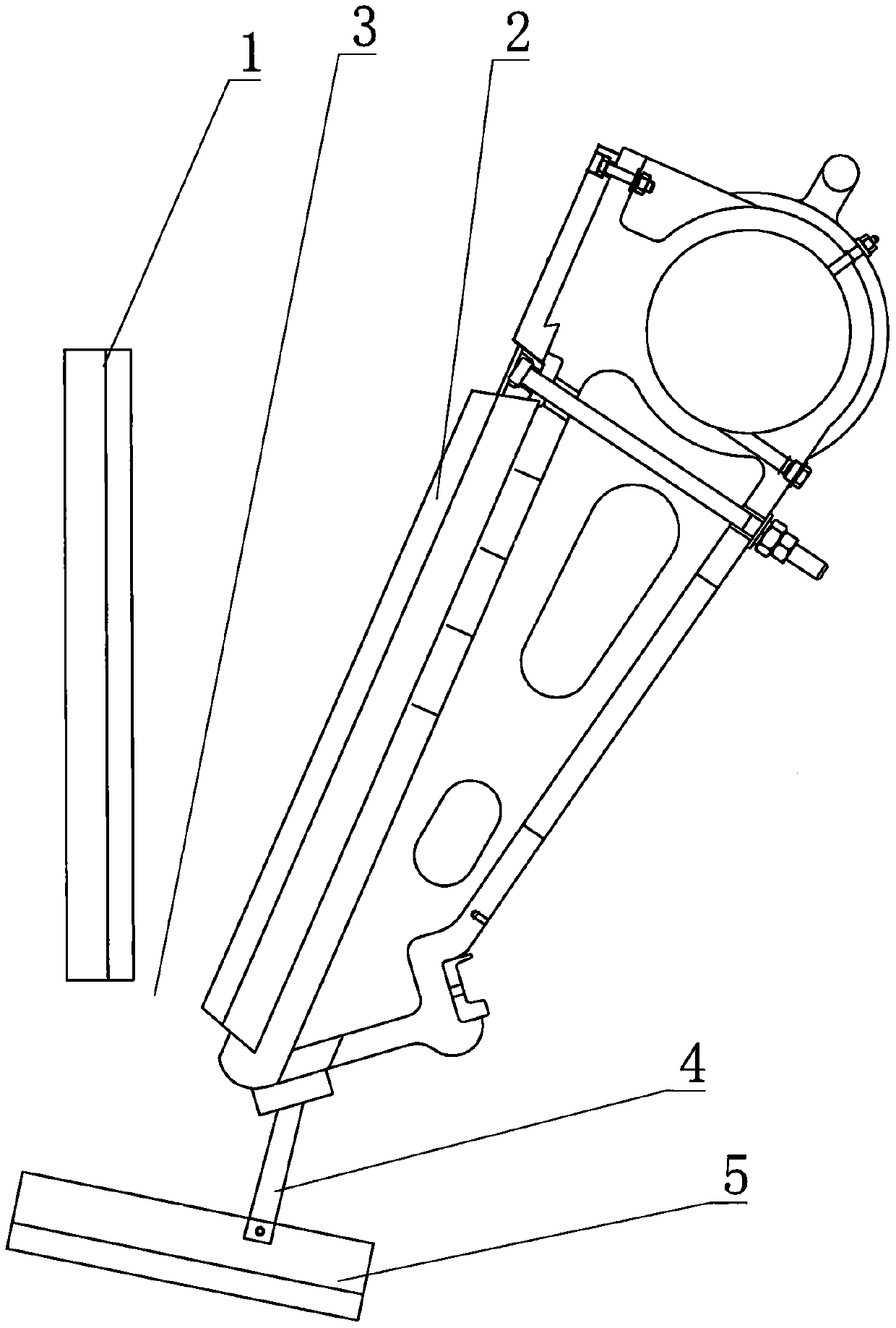

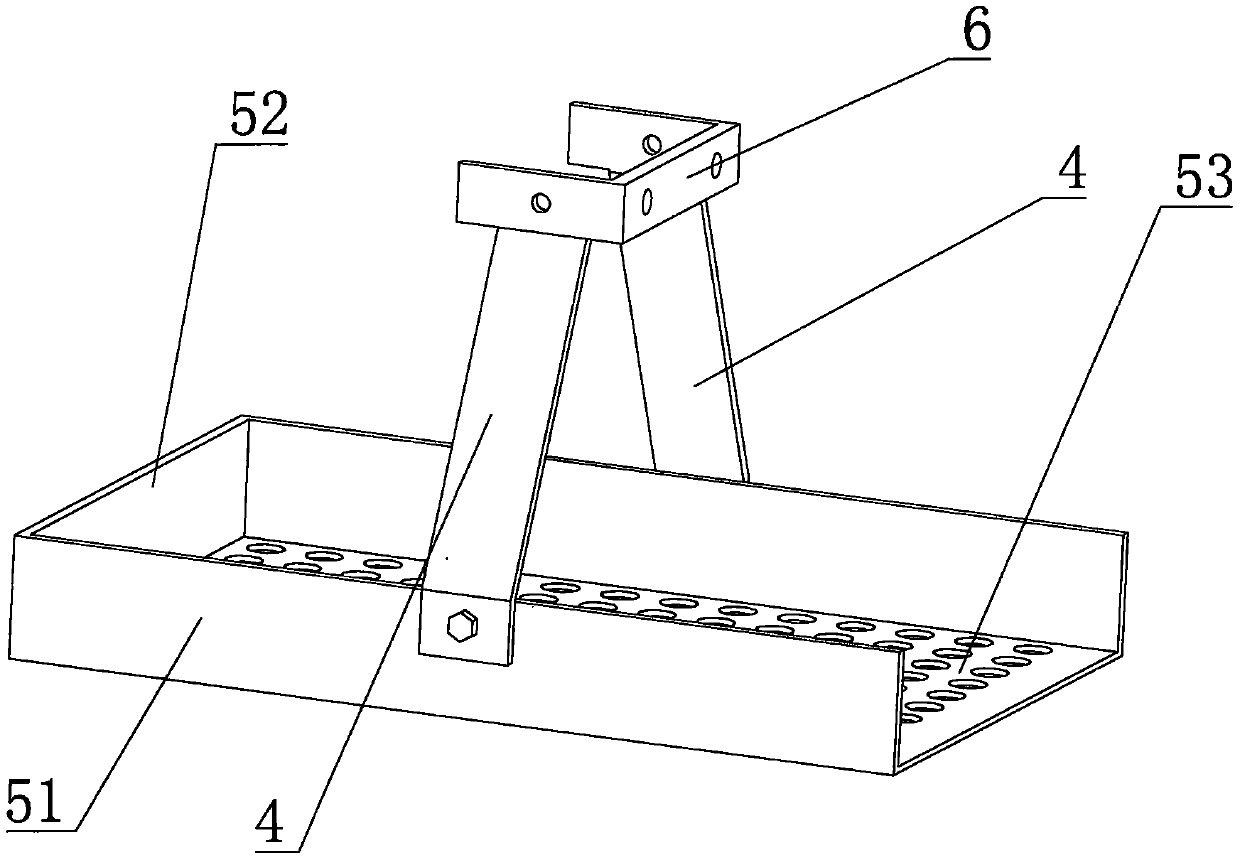

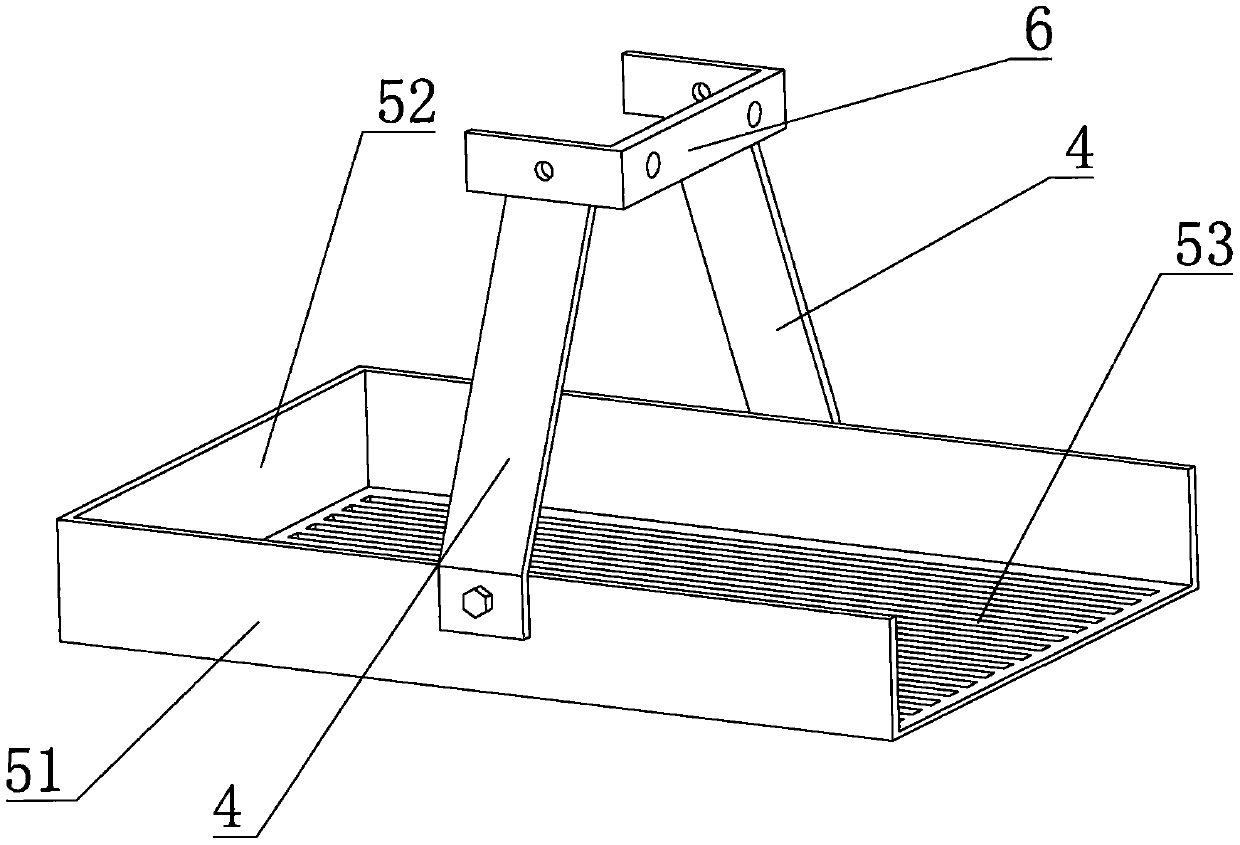

[0030] Embodiment 1: as Figure 1-3 As shown, a crushing pair with a screen frame includes a fixed jaw 1 and a movable jaw 2, a crushing cavity is formed between the fixed jaw 1 and the movable jaw 2, and the movable jaw 2 is driven by a driving device to approach or move away from the fixed jaw Jaw 1 crushes materials, and the bottom of the crushing cavity is provided with a discharge port 3; the lower part of the movable jaw 2 is equipped with a connecting arm 4, and a screen frame 5 is installed at the lower end of the connecting arm 4, and the screen frame 5 is located at the discharge port 3 Below; there are two connecting arms 4, the lower ends of which are respectively symmetrically installed on the two side plates 51 of the screen frame through high-strength bolts, and the upper ends are connected together by a U-shaped mounting part 6, and the U-shaped mounting part 6 and the two The root connecting arm 4 is integrally formed, and the U-shaped mounting part 6 is provi...

Embodiment 2

[0031] Embodiment 2: as image 3 As shown, the difference from Example 1 is that a double-layer sieve plate is arranged in the screen frame 5, and the two layers of sieve plates are parallel to each other, and are arranged in the screen frame from top to bottom. Defined as the first sieve plate 531 and the second sieve plate 532, the first sieve plate 531 is a sieve bar structure, the second sieve plate 532 is a screen mesh structure, and the screening gap of the first sieve plate 531 is larger than that of the second sieve plate 532 In the screening gap, after the mineral material is crushed by the crushing pair, it falls from the discharge port 3 onto the first sieve plate 531 of the screen frame 5, and the screen frame 5 moves with the movable jaw 2 to screen the mineral material. Mineral materials larger than the screening gap of the first sieve plate 531 are discharged from the corresponding discharge port, and mineral materials with a particle size smaller than the scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com