Novel bale breaker

A baler machine, a new type of technology, applied in the direction of grain processing, etc., can solve the problems that cannot be solved, such as loose dust, uneven force on the supporting wheel shaft, and asynchronous rotation of the supporting wheel, so as to improve the working environment and environmental protection pressure, and the effect of baling Good, avoid the effect of material scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

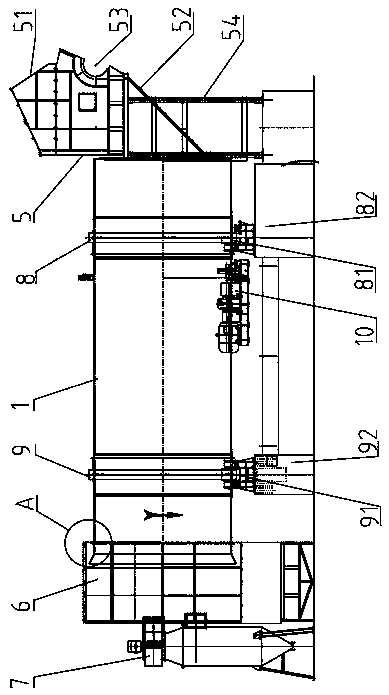

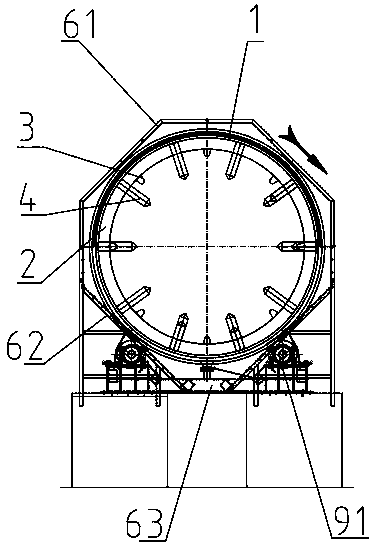

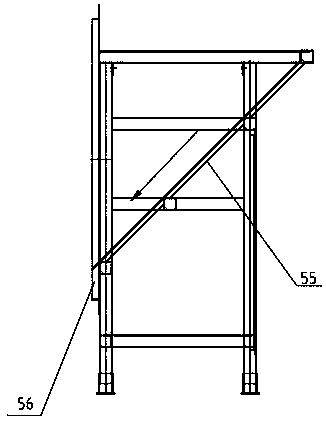

[0051] Such as Figure 1 to Figure 15 As shown, a new type of bulk packaging machine of the present invention includes a rotating cylinder 1 arranged horizontally. The two ends of the rotating cylinder 1 are respectively set as a feed end and a discharge end, and a spiral bulk packaging mechanism is arranged in the rotating cylinder. A driving mechanism for driving the rotation of the rotating cylinder 1 is connected outside.

[0052] The feeding end of the rotating cylinder 1 is provided with a feeding sealing cover 5, and the feeding sealing cover is connected with a feeding dust removal mechanism, which not only avoids material scattering, but also realizes dust removal on the feeding side and avoids dust overflow from the feeding side .

[0053] The feed sealing cover 5 includes a feeder base 52 and a feeder shield 51. The feeder base 52 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com