Bending device

The technology of a bending device and a flat needle is applied in the field of bending devices, which can solve the problems of inconvenient connection and difficult bending process of the bending device, and achieve the effect of avoiding breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

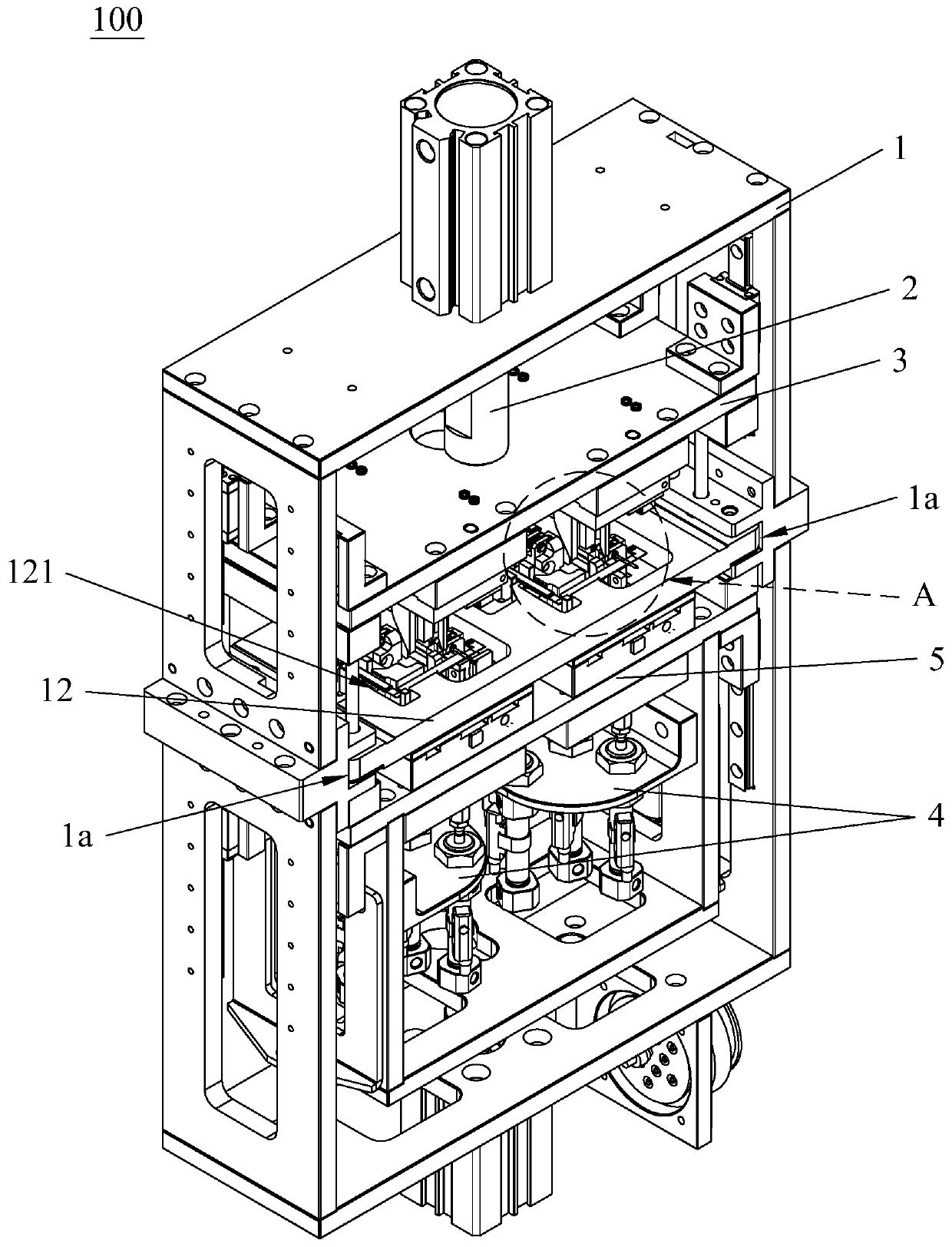

[0028] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

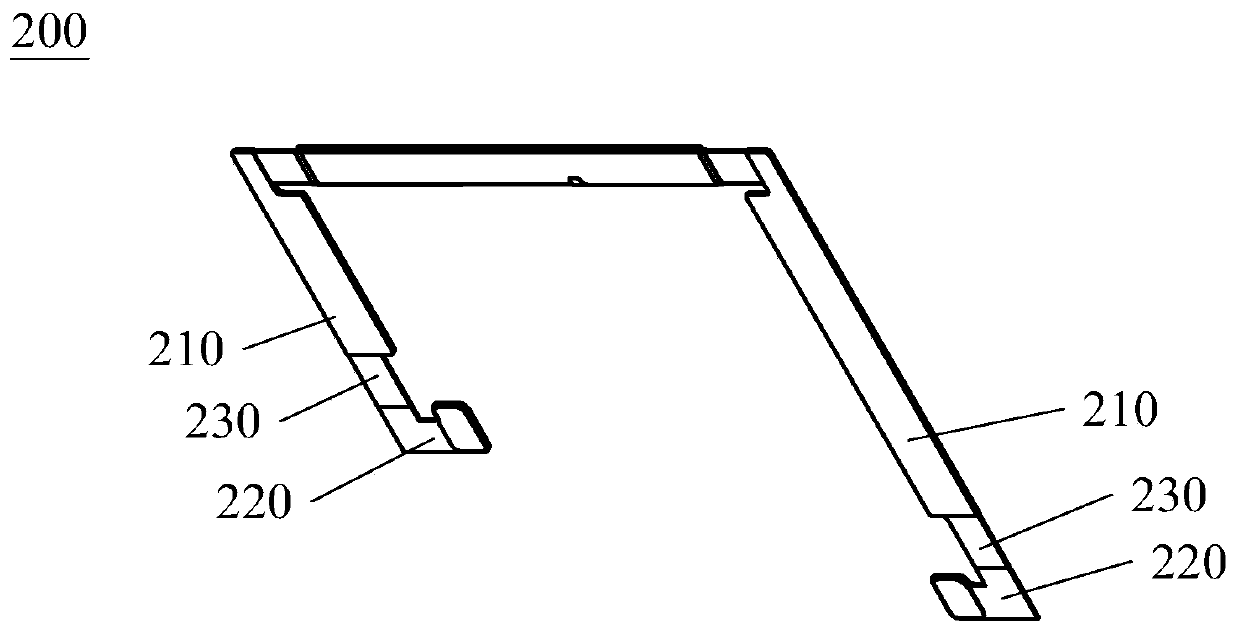

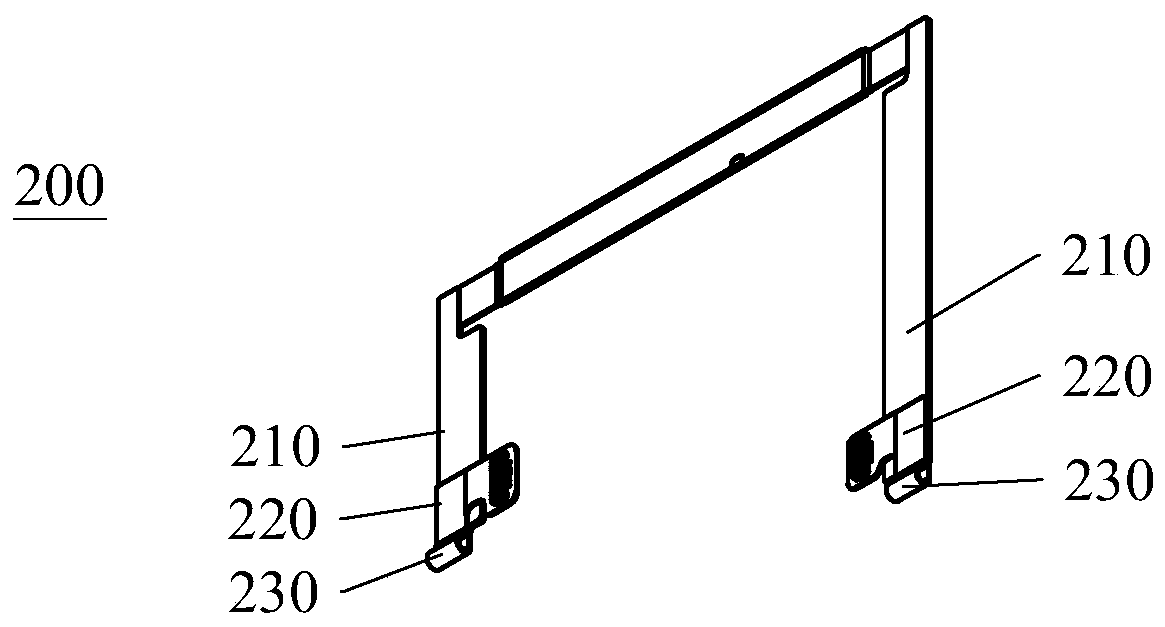

[0029] The present invention provides a bending device 100, which is used for 180-degree bending of a workpiece 200, please refer to the attached Figure 1 to Figure 2 , the workpiece 200 includes a first elongated plate 210, a second elongated plate 220 and an arc bending portion 230, the arc bending portion 230 is located between the first elongated plate 210 and the second elongated plate 220, and the second The elongated plate 220 is bent toward the first elongated plate 210, and the first elongated plate 210 and the second elongated plate 220 are attached to each other after bending, in order to avoid the first elongated plate 210 and the second elongated plate The bending position between 220 is broken, and the arc bending part 230 needs to be bent into an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com