Button cell battery production line

A button-type battery and production line technology, applied in the field of automation equipment, can solve the problems of uncontrollable sealing instant time, no reports in technical literature, easy rebound of plastic deformation materials, etc., to achieve the effects of convenient control, increased speed and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the claims of the present invention are not limited by the specific embodiments.

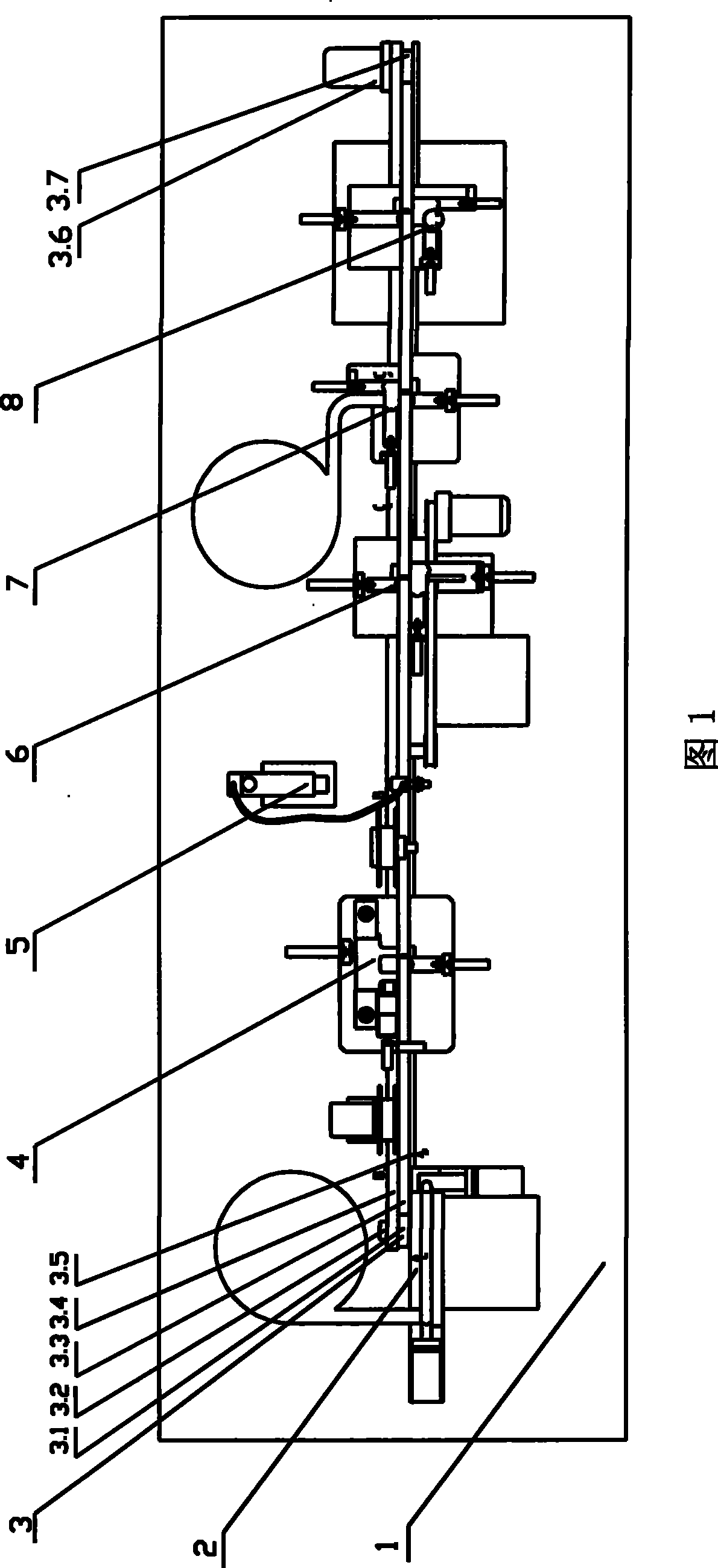

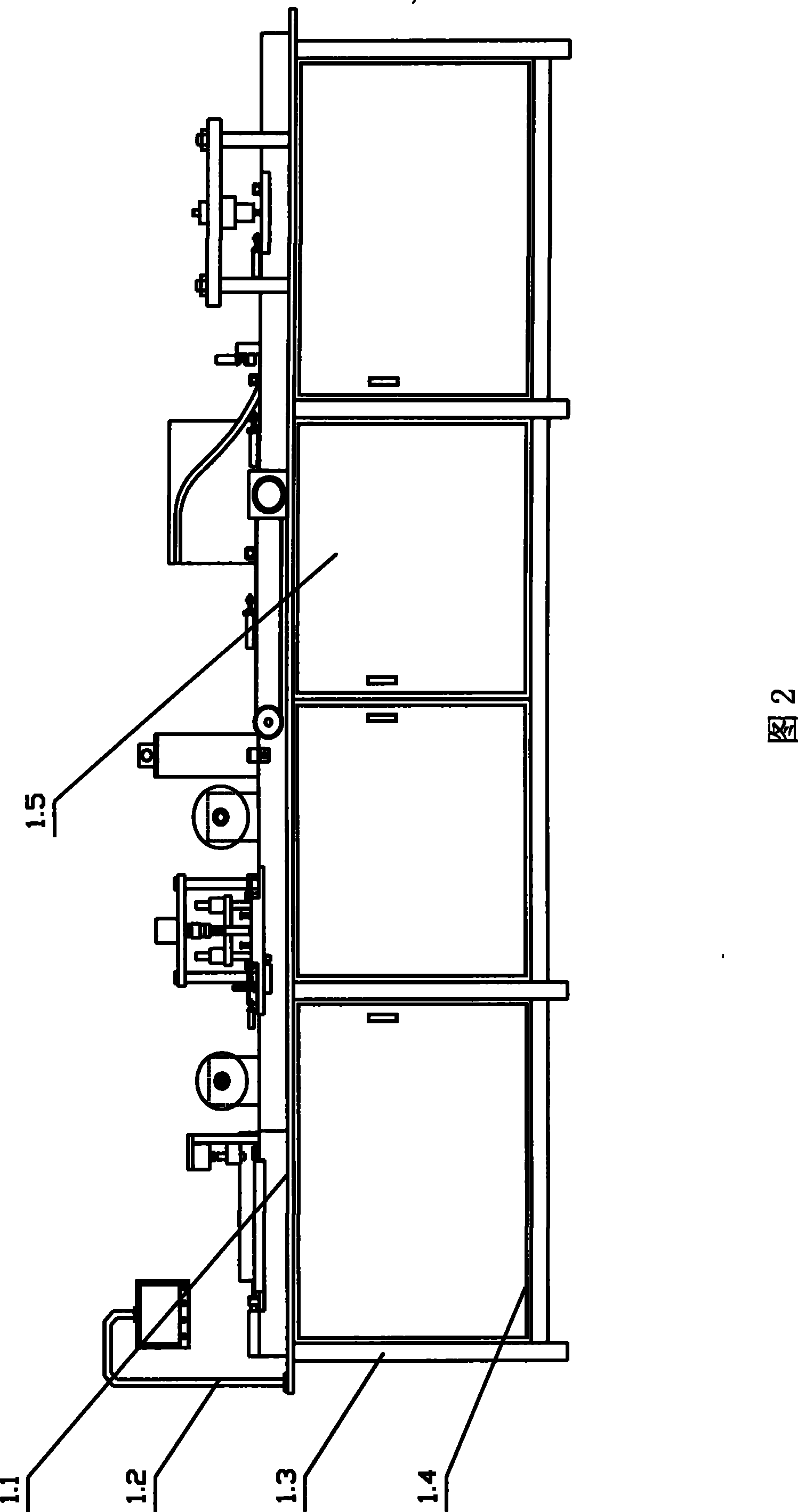

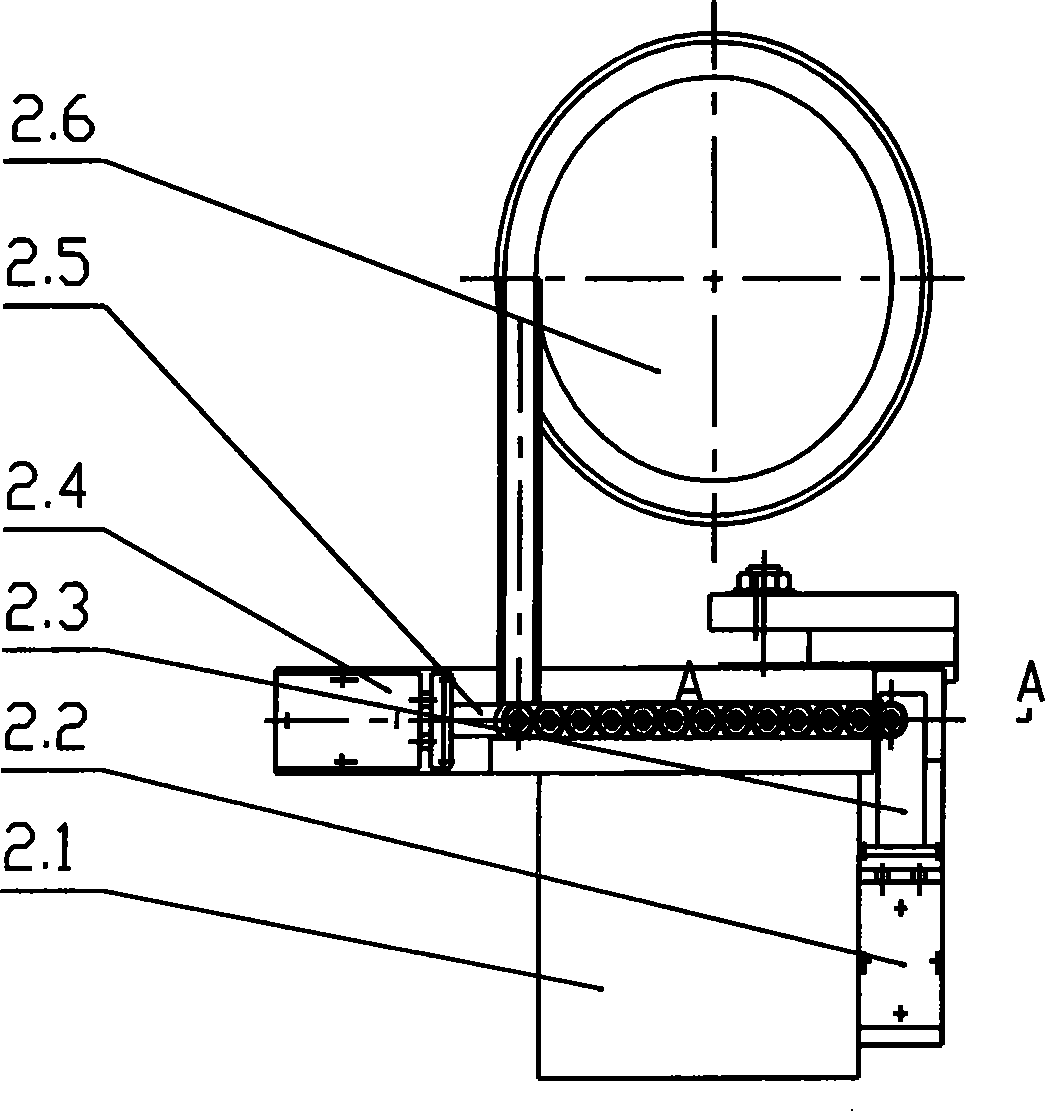

[0047] The button battery production line designed by the present invention (hereinafter referred to as the production line, referring to Fig. 1-13) includes a frame assembly 1, a lithium sheet upper mechanism 2, a main transmission mechanism 3, a paper cutting mechanism 4, a liquid injection mechanism 5, and a manganese sheet upper mechanism 6. Positive electrode shell adding mechanism 7, sealing mechanism 8, pneumatic control system 9, electrical control system 10 and control program.

[0048] Described frame assembly 1 (referring to Fig. 1, 2) comprises big workbench 1.1 and the frame 1.3 that is fastened on the lower surface of big workbench 1.1; A control cabinet 1.5 is installed on the upper part of the bottom plate 1.4 under the frame; the upper lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com