Intelligent roadway slotting robot

A robot and roadway technology, which is applied in the field of intelligent roadway slotting robots, can solve the problems of low slotting precision, small working range of the working arm, and no effective slotting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described below in conjunction with the drawings, which is apparent from the accompanying drawings. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

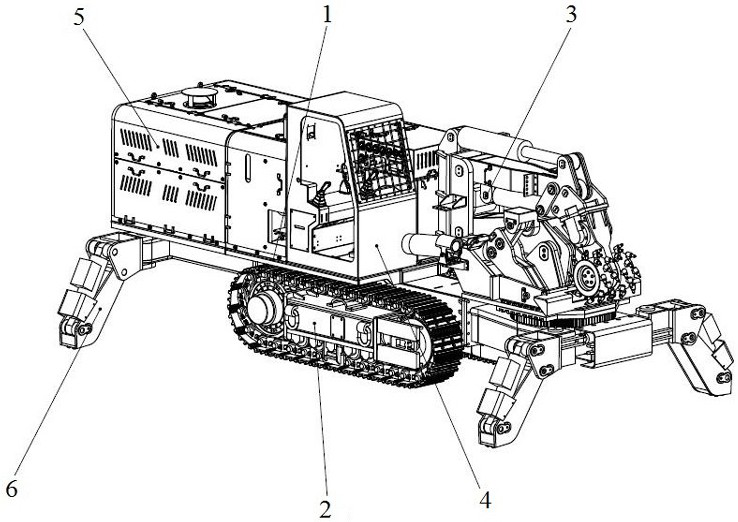

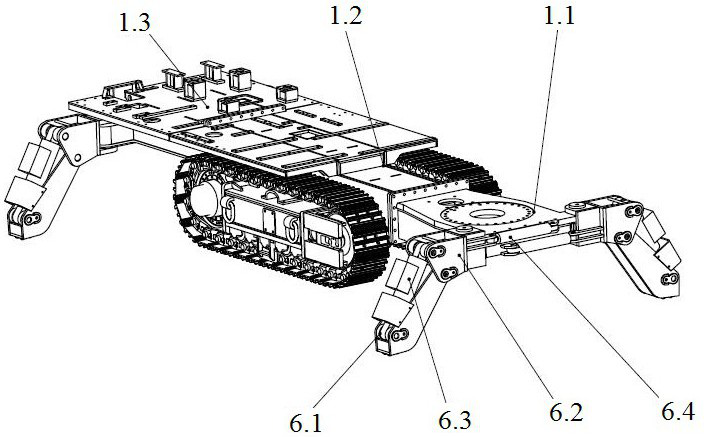

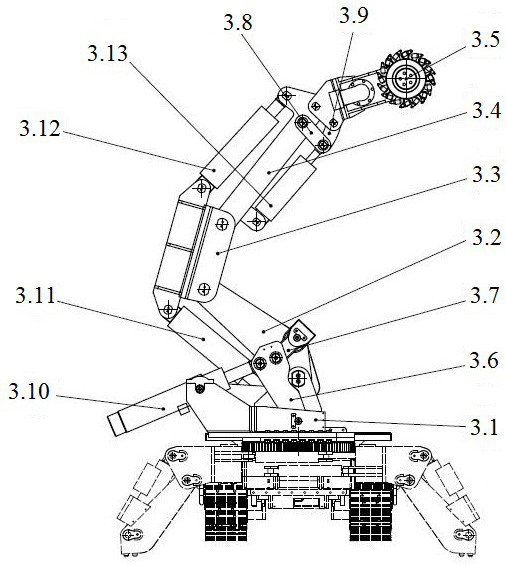

[0034] This embodiment provides an intelligent robot slotted tunnel, comprises a main frame 1, two traveling portion, the cutting portion 3, a cab 4, for providing power to the intelligent robot grooved roadway 5 and powertrain grooving for stabilizing the fuselage during stable support system 6; cutting unit 3, a cab 4 and powertrain 5 mounted on the main frame 1, composed of the body.

[0035] The main chassis 1 comprises a front frame connected by bolts 1.1, intermediate frame and the rear frame 1.2 1.3; cutting portion 3 is provided on the front chassis 1.1; cab 4 is provided on the intermediate frame 1.2; 5 disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com