Rice processing and quantitative packaging device

A technology for rice processing and mounting racks, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of inaccurate rice packaging and inability to remove rice impurities, and achieve the effect of improving the passing efficiency and reducing the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

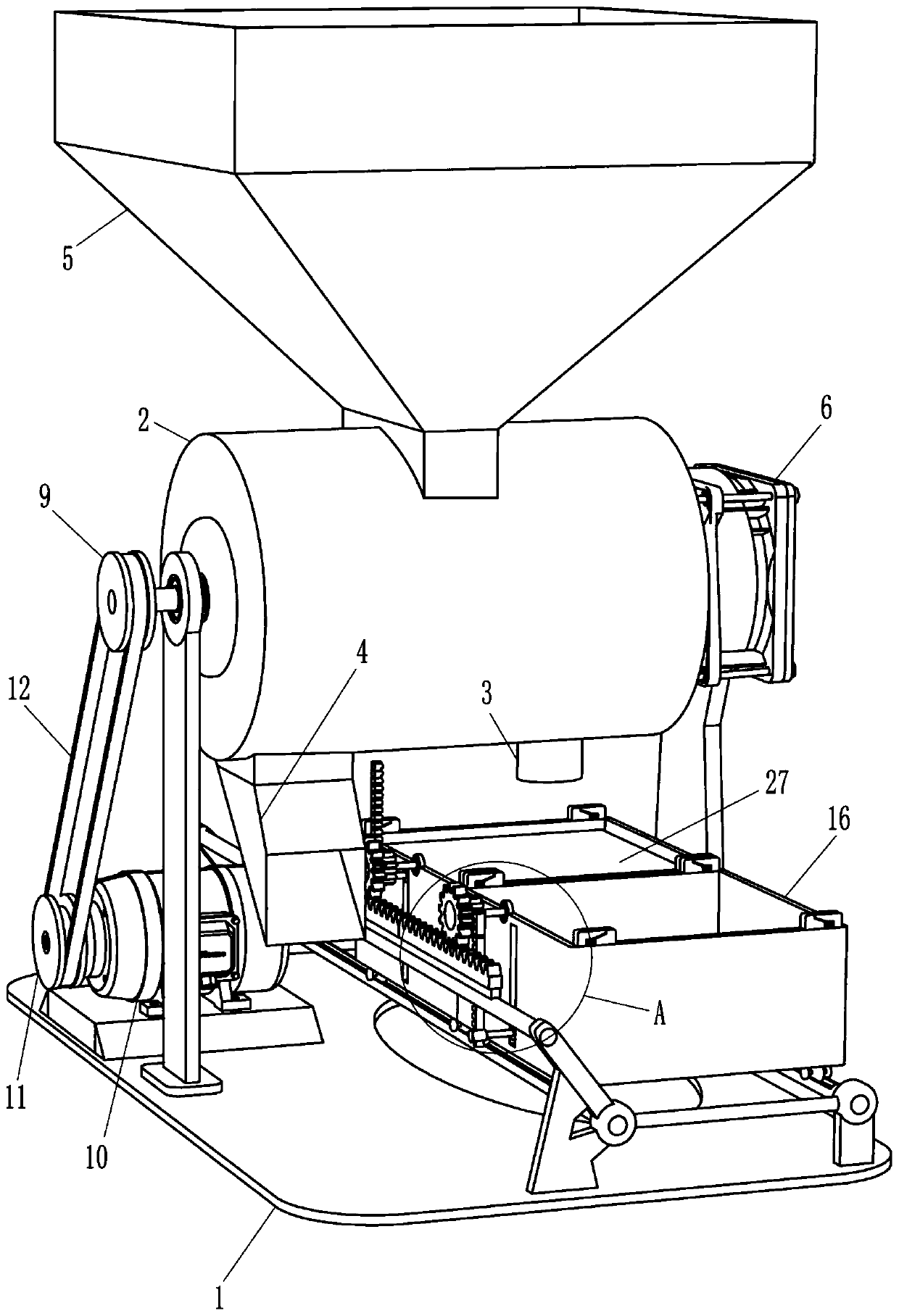

[0019] A quantitative packaging device for rice processing, such as figure 1 with figure 2 As shown, it includes a mounting frame 1, a cylinder 2, a discharge pipe 3, a defective product discharge pipe 4, a storage hopper 5, a transmission part, a collecting part and a clamping assembly. The top of the mounting frame 1 is provided with a cylinder 2, and the cylinder 2 There is a discharge pipe 3 on the right side of the bottom, the discharge pipe 3 communicates with the cylinder 2, the left side of the bottom of the cylinder 2 is provided with a defective product discharge pipe 4, the defective product discharge pipe 4 communicates with the cylinder 2, and the top of the cylinder 2 A storage hopper 5 is provided, and the storage hopper 5 communicates with the cylinder 2, and the transmission part for quantitative feeding is provided in the cylinder 2, and the collection part for collecting rice by sliding is installed on the installation frame 1, and the collection part A cl...

Embodiment 2

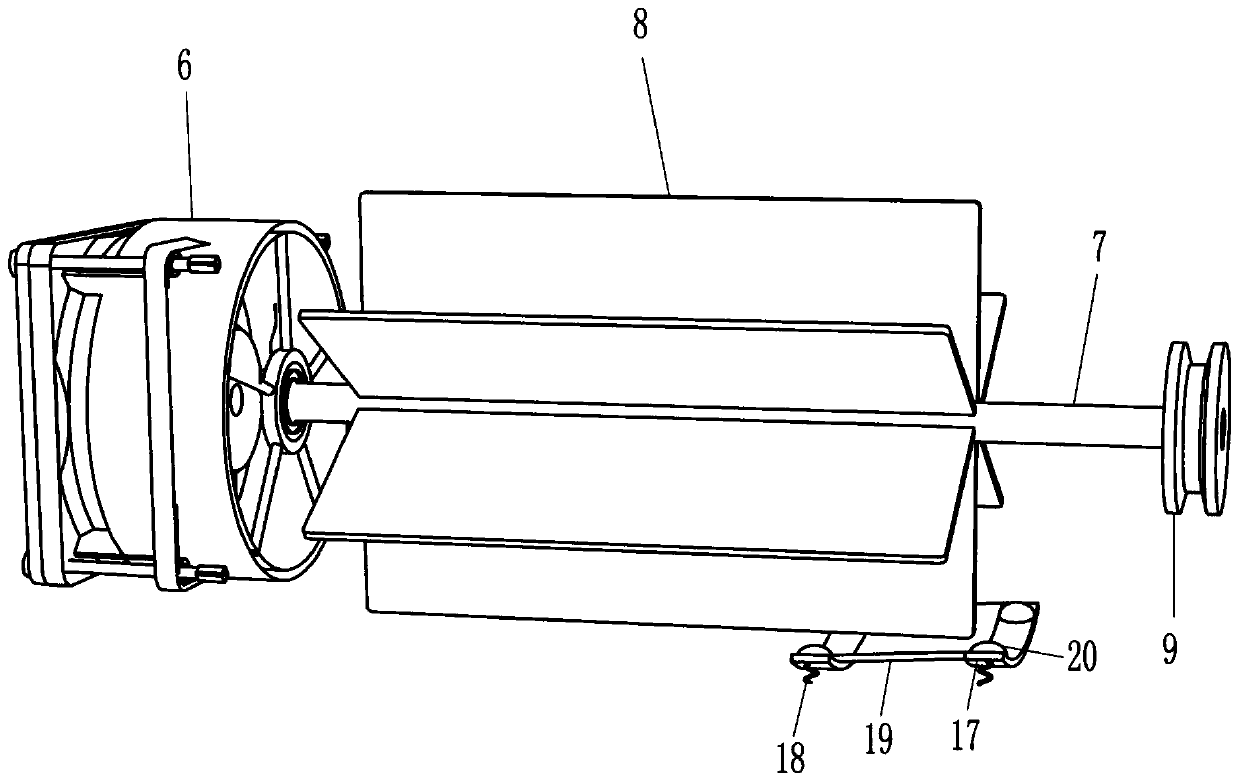

[0028] On the basis of Example 1, such as figure 2 As shown, in order to improve the practicability of the equipment, it also includes an arc-shaped mounting plate 17, a second spring 18, an arc-shaped net plate 19 and a bump 20. There are two slides at the connection between the defective product outlet tube 4 and the cylinder 2. The arc-shaped mounting plate 17, the second spring 18 is welded between the arc-shaped mounting plate 17 and the cylinder 2, the arc-shaped mesh plate 19 is arranged between the arc-shaped mounting plate 17, and the top of the arc-shaped mounting plate 17 is welded with convex Block 20, the protrusion 20 cooperates with the rotating plate 8.

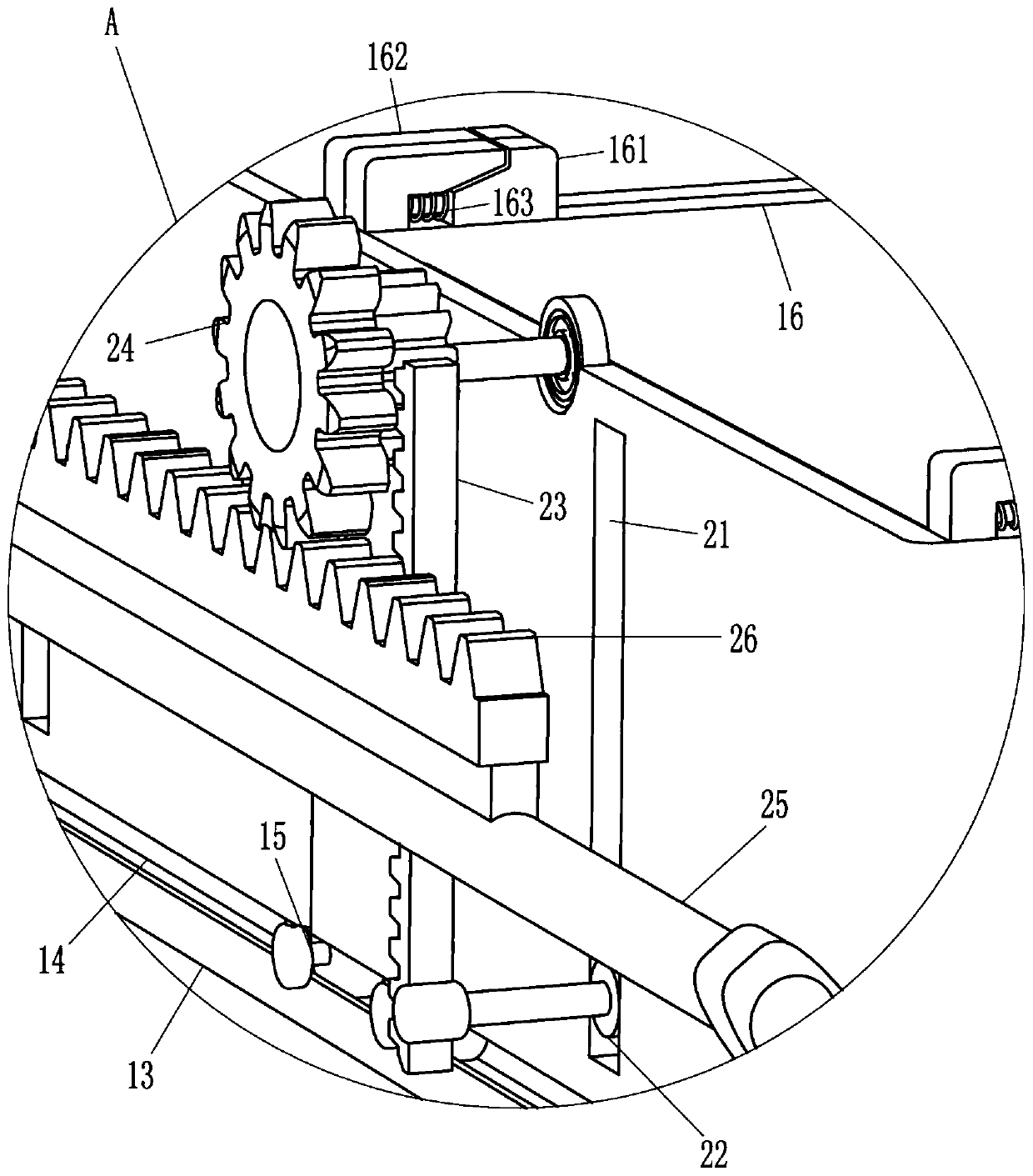

[0029] Such as figure 1 with image 3 As shown, in order to improve the working efficiency of the equipment, it also includes a slider 22, a first rack 23, a convex gear 24, a mounting rod 25, a second rack 26 and a bearing plate 27, and a slot is opened on the left side of the storage box 16. 21, sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com