Quarter turn conveying device and working method thereof

A conveying device and right-angle turning technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of inconvenient speed adjustment, inconvenient loading and unloading, and inability of the conveying device to turn, so as to solve the inconvenience of speed regulation, The effect of convenient speed adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

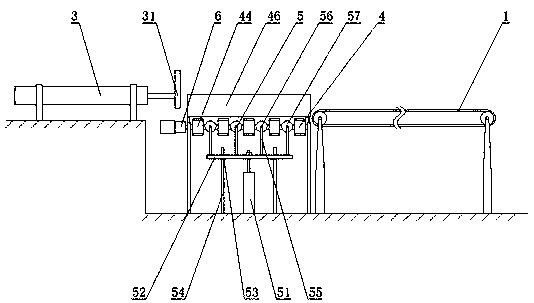

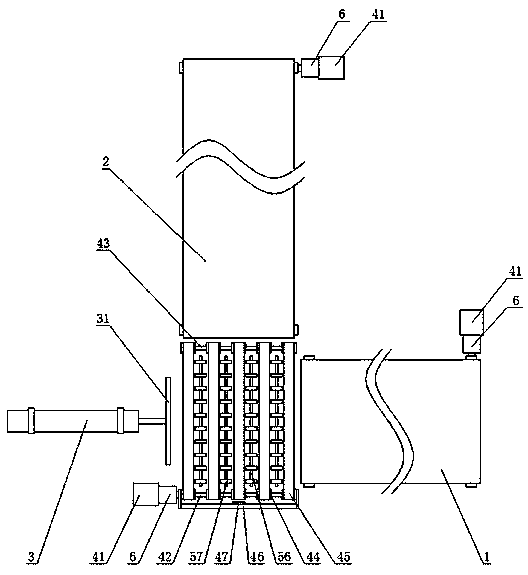

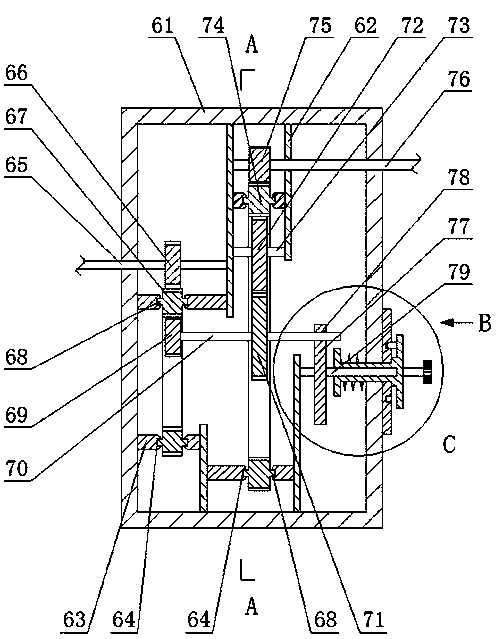

[0032] The embodiment of the present invention provides a right-angle turning conveying device and its working method. By setting the steering gear 4, the pulley unit 5 and the push cylinder 3, the conveyed goods can be moved by the pulley unit when moving from the belt conveyor B2 to the steering gear 4. 5 jacking up, and then pushed to the belt conveyor A1 by the push cylinder 3, so as to realize the automatic turning of the transported items, and solve the technical problem of inconvenient loading and unloading caused by the use of multiple conveying devices. By setting the transmission 6, it is convenient for the production line operators to adjust the speed of the conveying device, thereby solving the technical problem that the current conveying device is not convenient for speed regulation. By adjusting the adjustment wheel 77 in the transmission 6, the gear C71 can be meshed with different gears in the flywheel set 72 to obtain different transmission ratios; The wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com