Patents

Literature

33results about How to "Realize automatic turning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

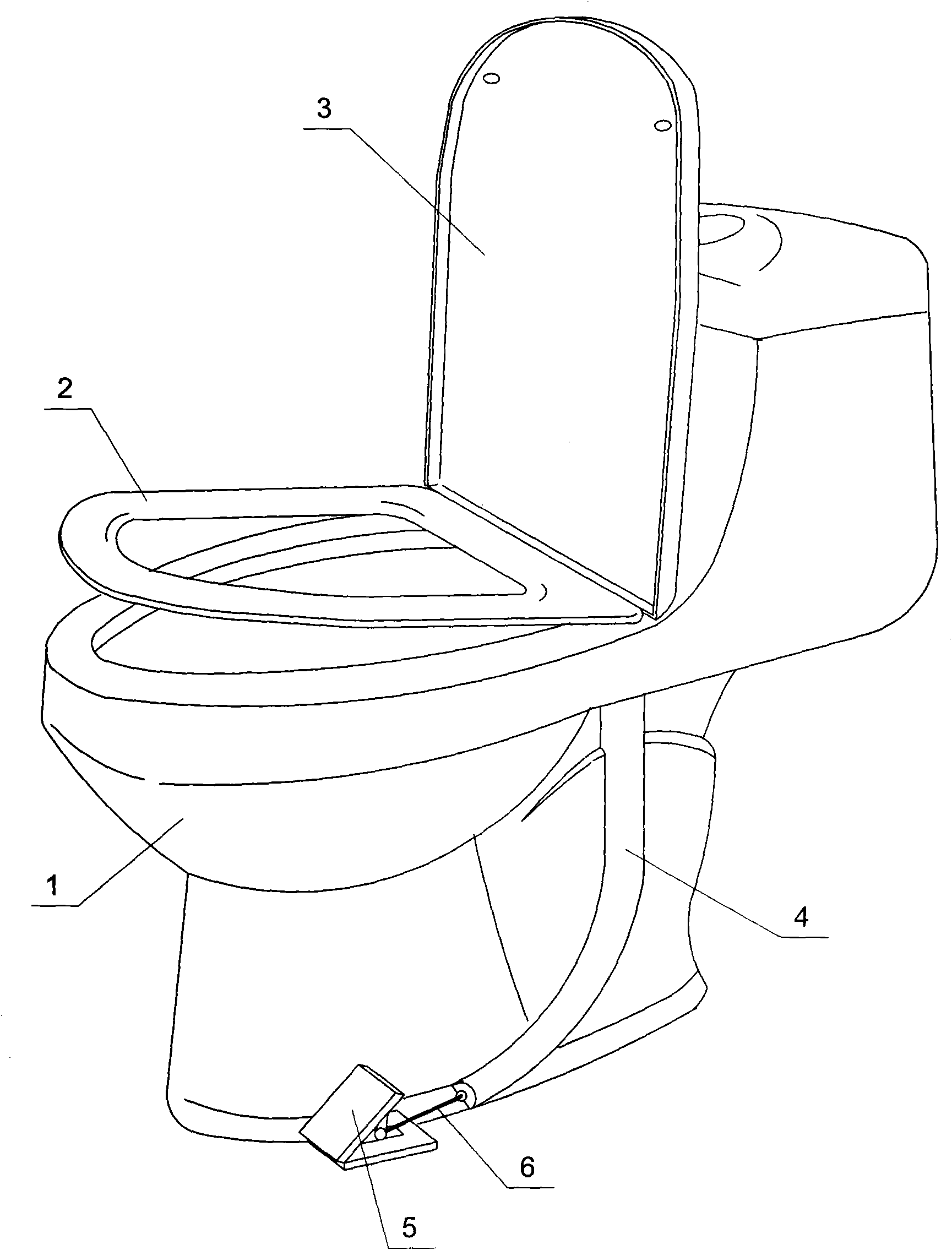

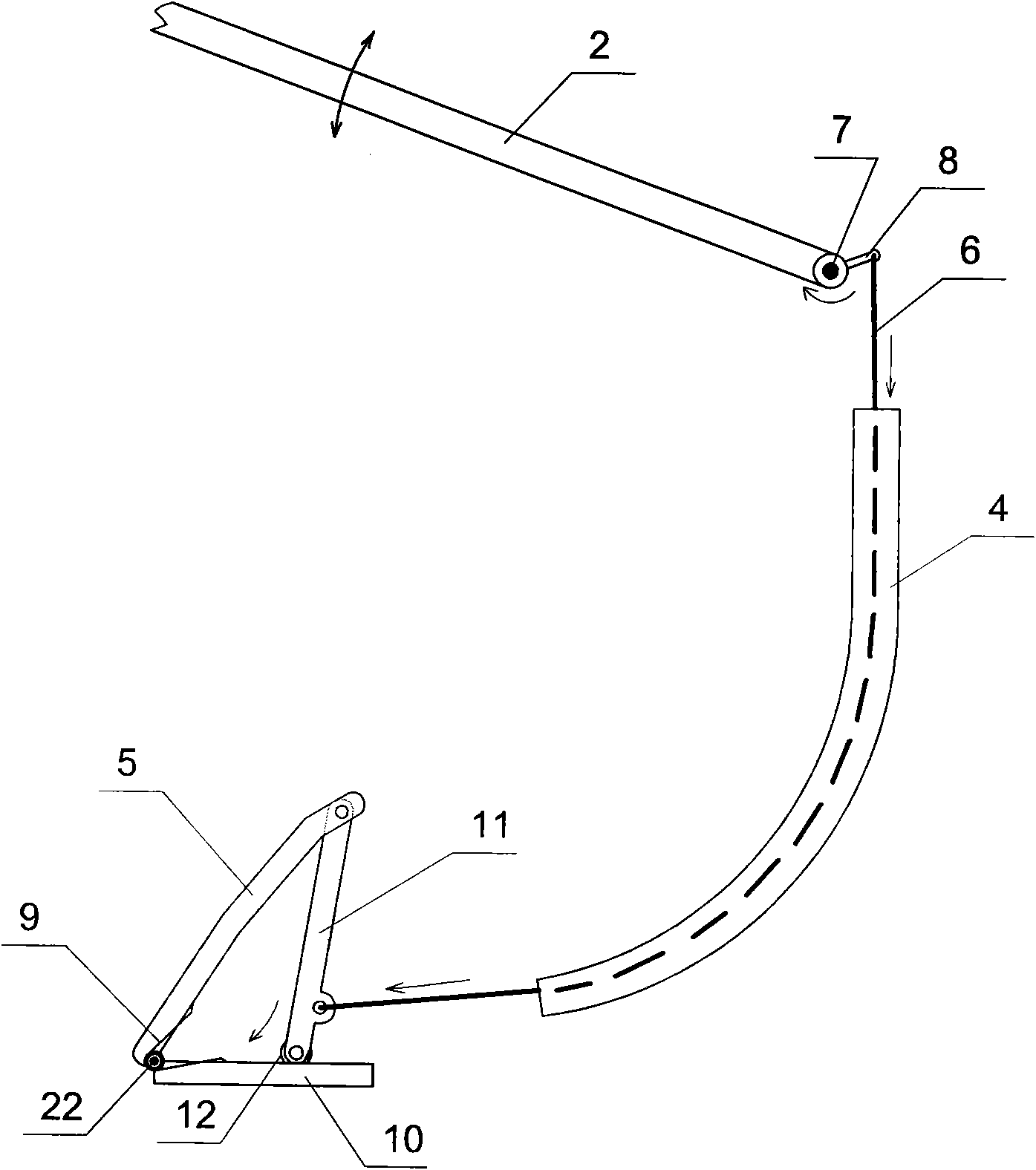

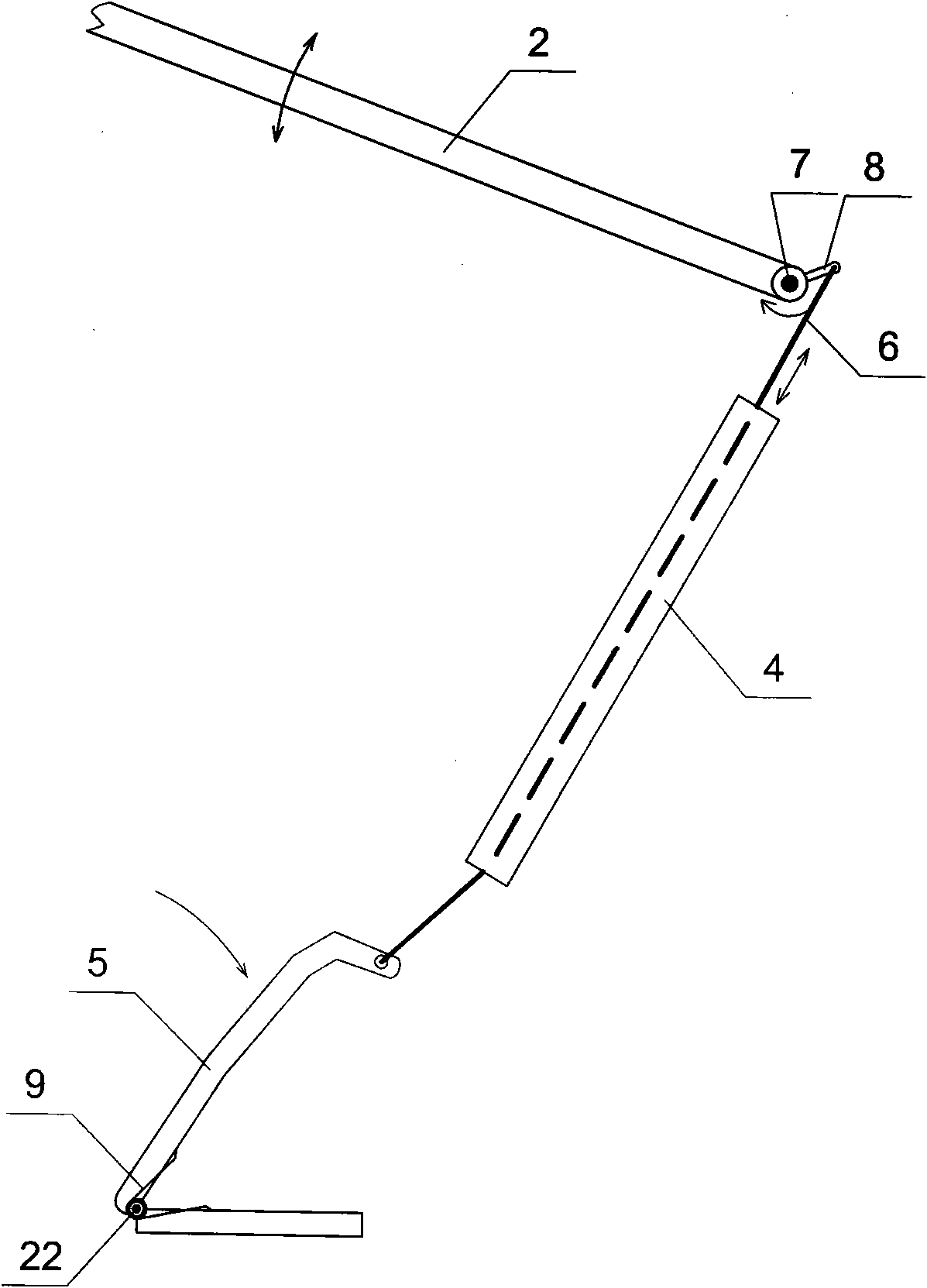

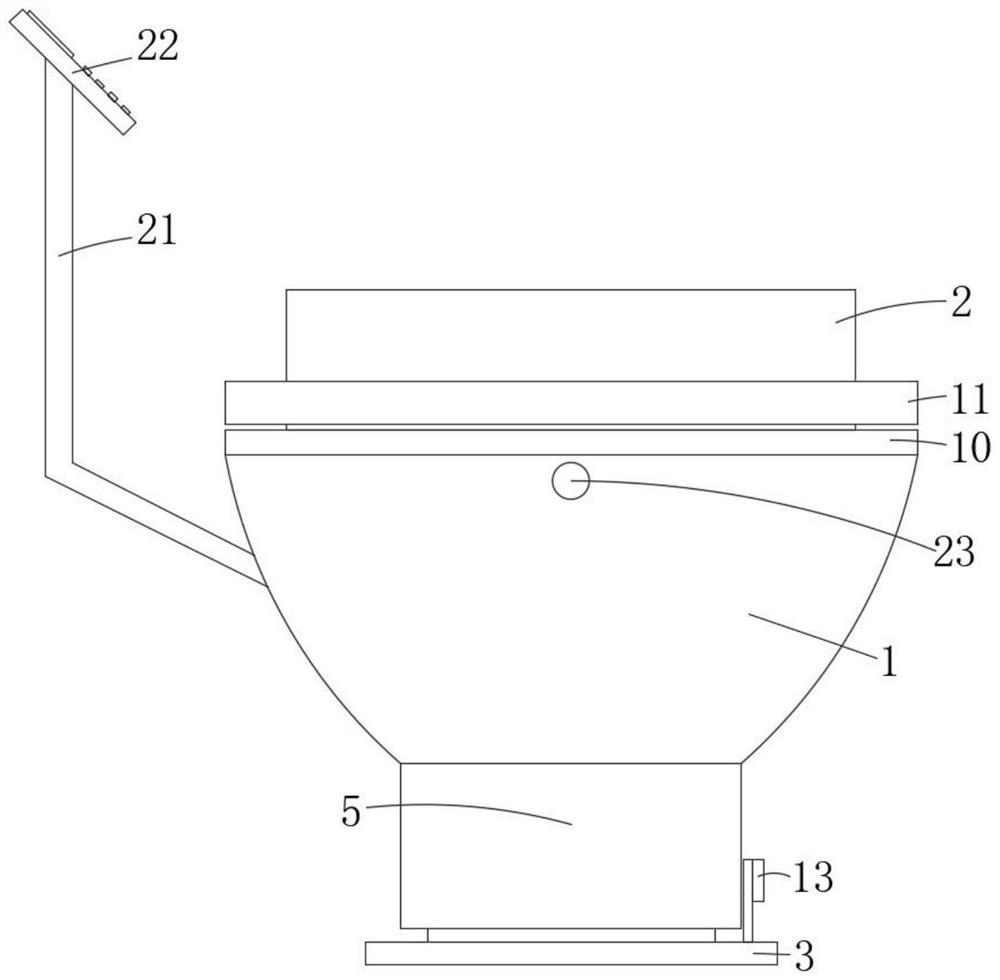

Pedal self-cover overturning toilet bowl

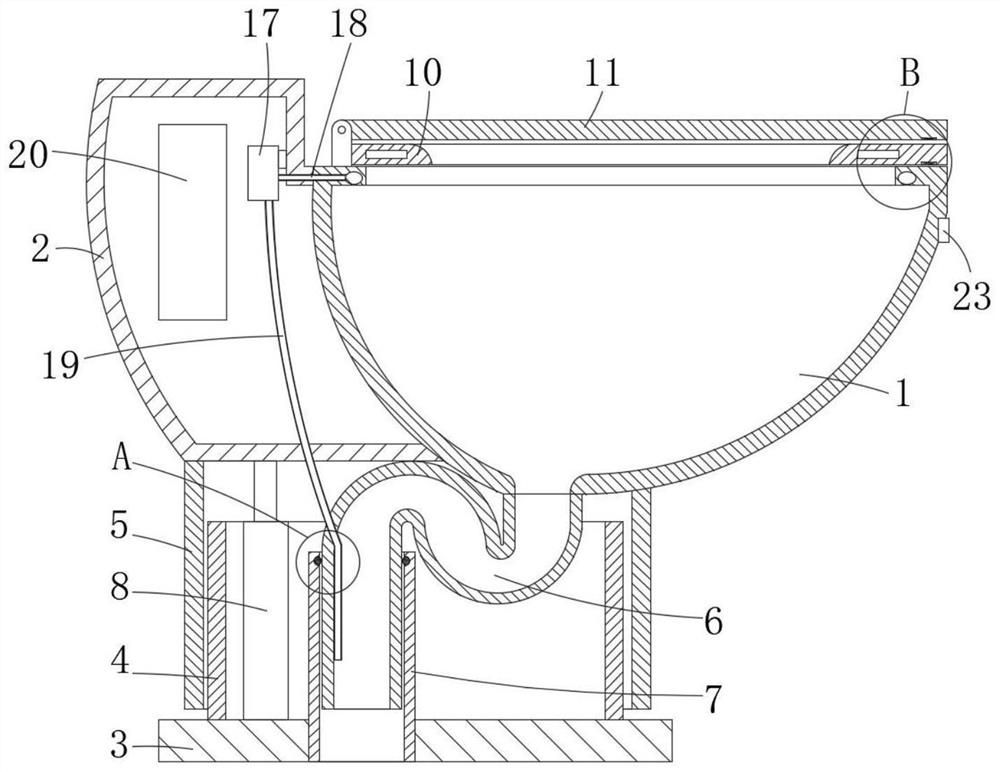

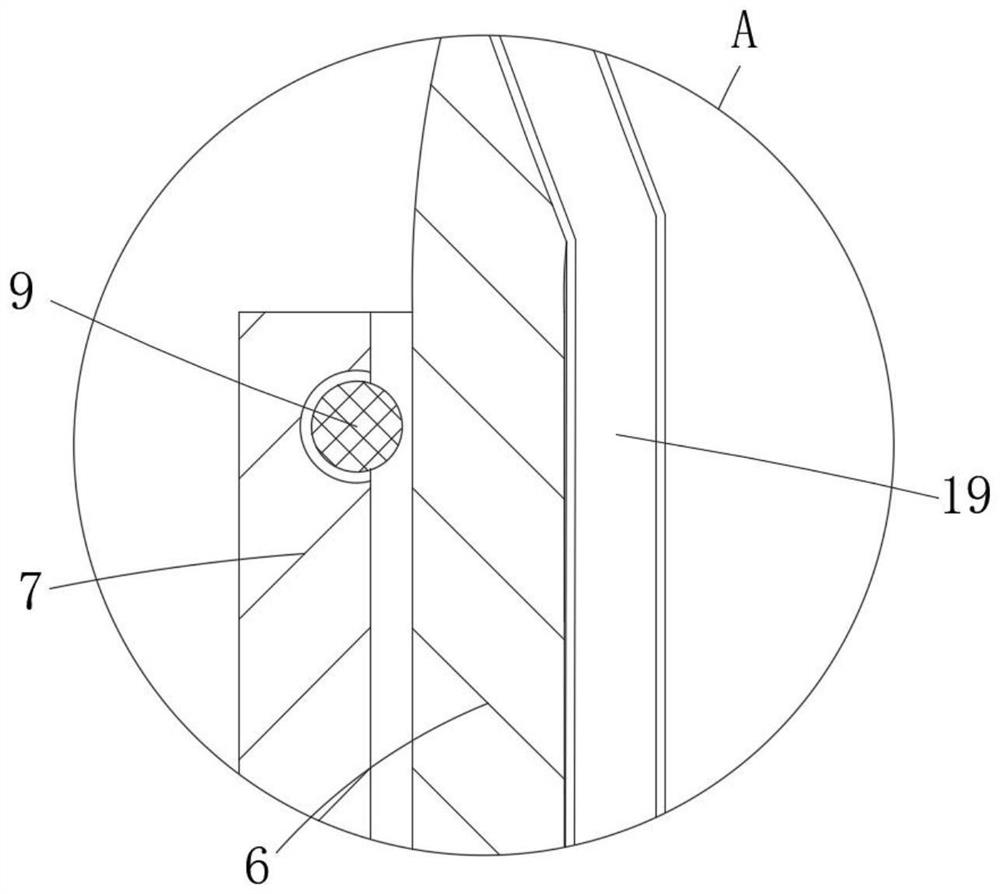

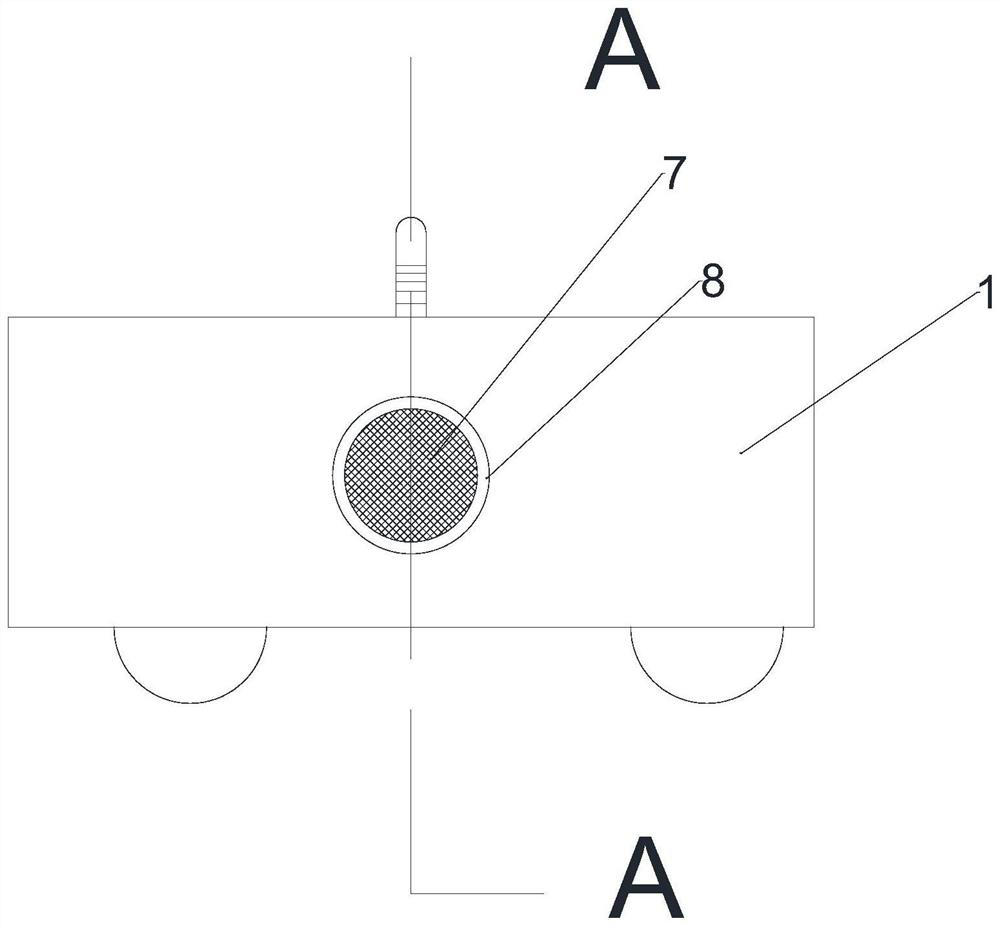

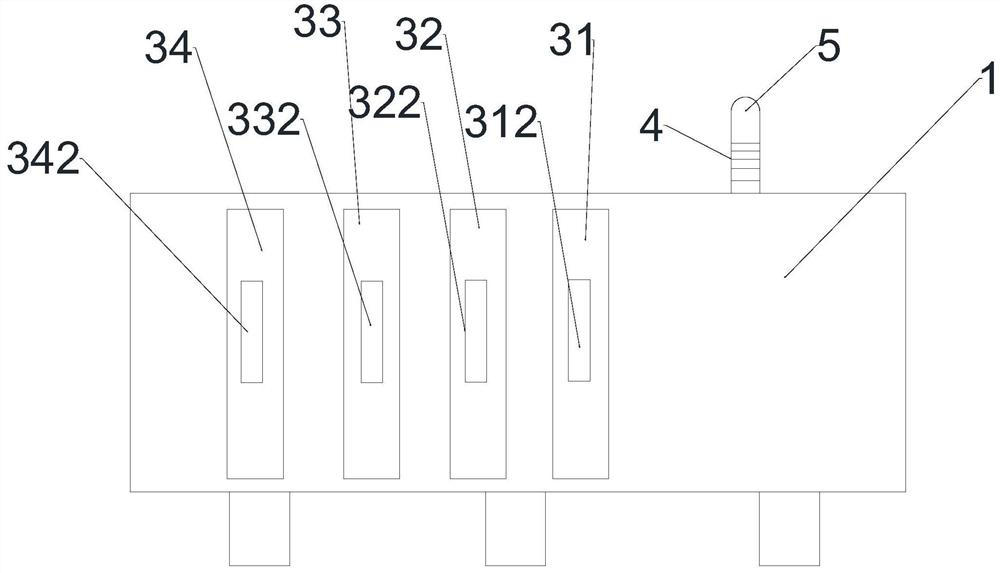

The invention relates to a pedal self-cover overturning toilet bowl. The toilet bowl comprises a toilet bowl body, a overturning cover and a toilet seat, wherein a device for controlling the toilet seat to automatically overturn is arranged at the root of the toilet seat; the automatic overturning device is fixed by at least one shifter lever in the hinging position of the root of the toilet seat; and one end of a telescopic drawing mechanism is connected with the shifter lever and the other end is connected with the pedal of a pedal mechanism so that when the pedal is pressed, the toilet seat can be overturned automatically. When using the pedal self-cover overturning toilet bowl, the toilet seat and even the overturning cover can be overturned automatically by pressing the pedal so that the toilet bowl is especially suitable to be used by family members of different sex, and when a men urinates, the men only needs to press the pedal lightly, thus the toilet bowl is convenient to use. The toilet bowl has simple structure, thus facilitating production-manufacturing or improvement; and the toilet bowl has extremely good use effect, thus facilitating popularization and application.

Owner:HENAN POLYTECHNIC UNIV

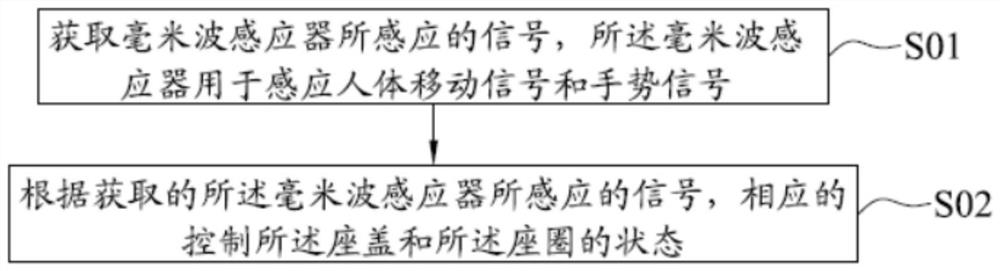

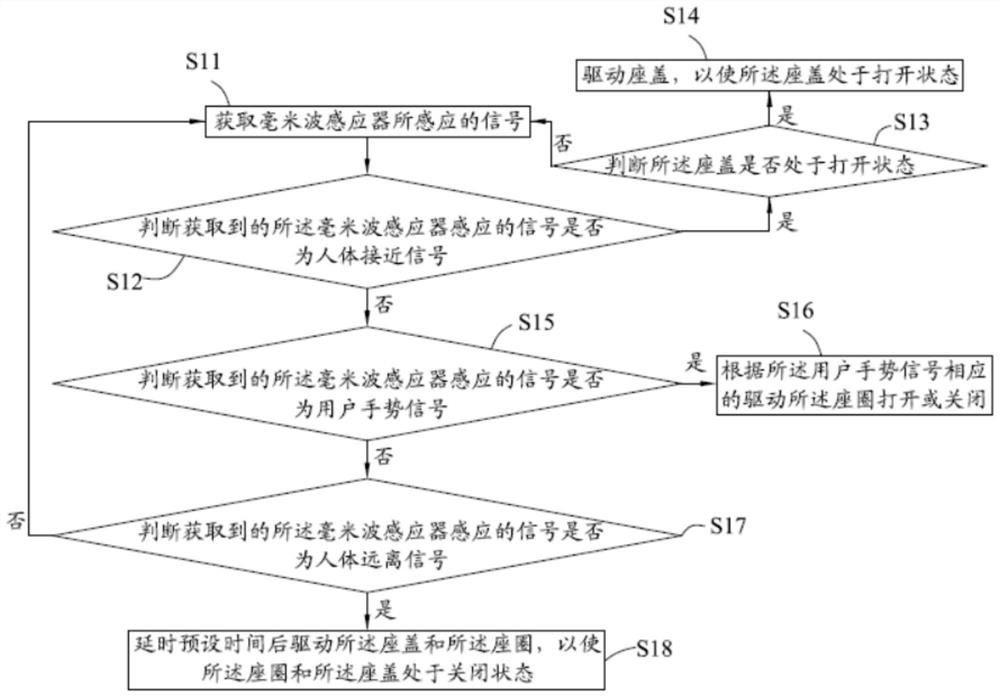

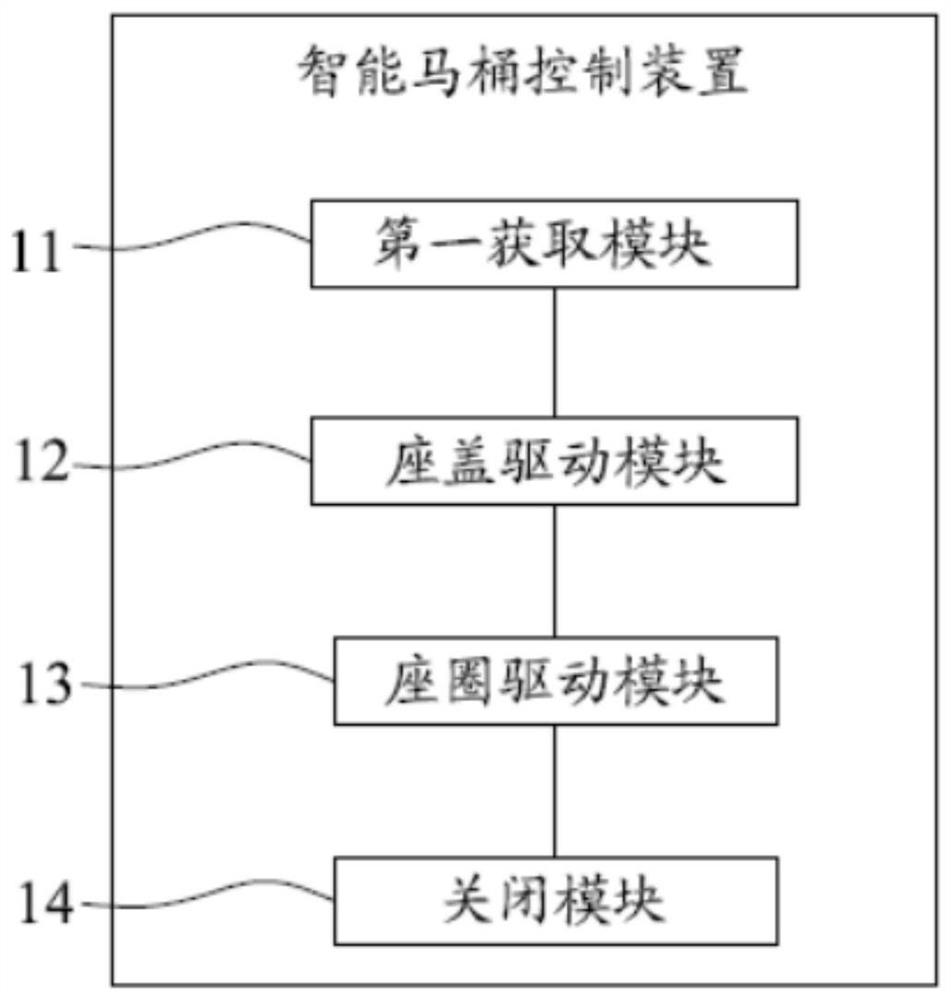

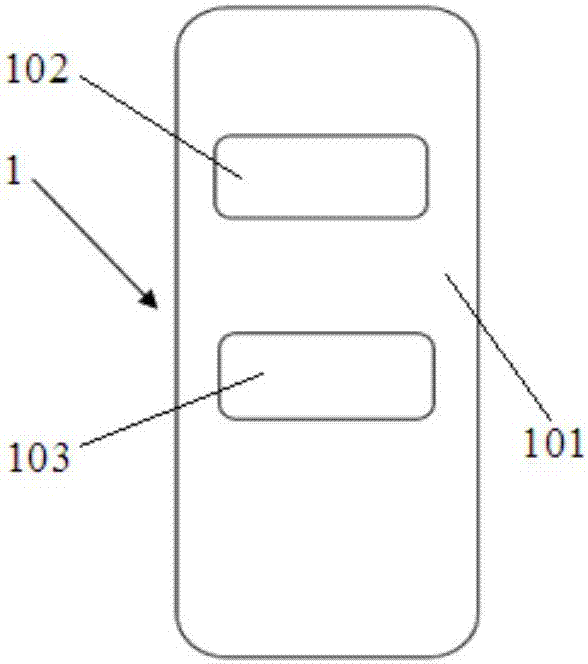

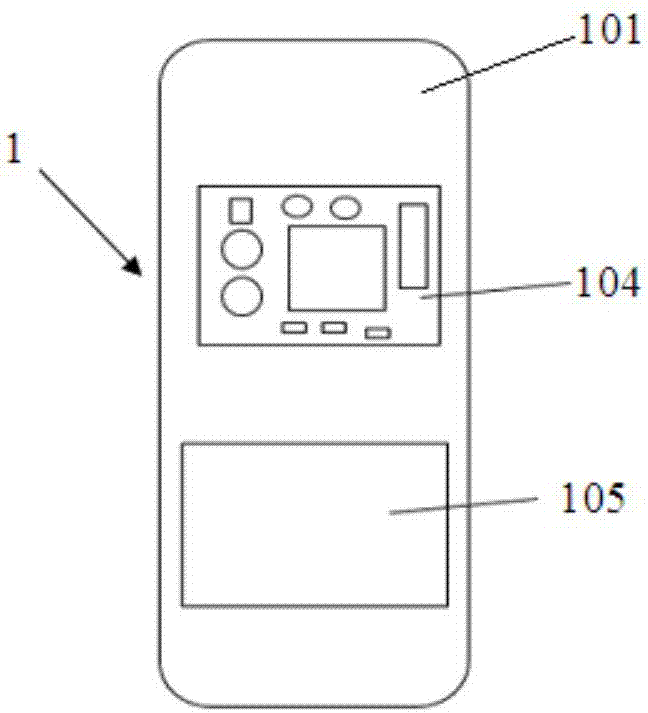

Intelligent closestool control method and device and intelligent closestool

InactiveCN112294171AReduce usageRealize automatic turningBathroom coversHuman bodyElectrical and Electronics engineering

The invention is suitable for the technical field of smart home, and provides an intelligent closestool control method and device and an intelligent closestool, and the intelligent closestool comprises a main body, a seat ring installed at the top of the main body, a seat cover covering the seat ring, and a millimeter wave sensor installed on the main body. The method comprises the following steps: acquiring a signal sensed by the millimeter wave sensor, wherein the millimeter wave sensor is used for sensing a human body movement signal and a gesture signal; and correspondingly controlling thestates of the seat cover and the seat ring according to the acquired signals sensed by the millimeter wave sensor. The millimeter wave sensor capable of sensing the human body movement signal and thegesture signal is arranged on the closestool, the seat cover and the seat ring of the closestool are correspondingly controlled according to the human body movement signal and the gesture signal, theautomatic ring turning and cover turning functions are achieved, the use of devices is reduced, the millimeter wave sensor is installed without drilling, the cost is reduced, and the disassembly, assembly and attractiveness are not affected.

Owner:SHENZHEN TOPBAND

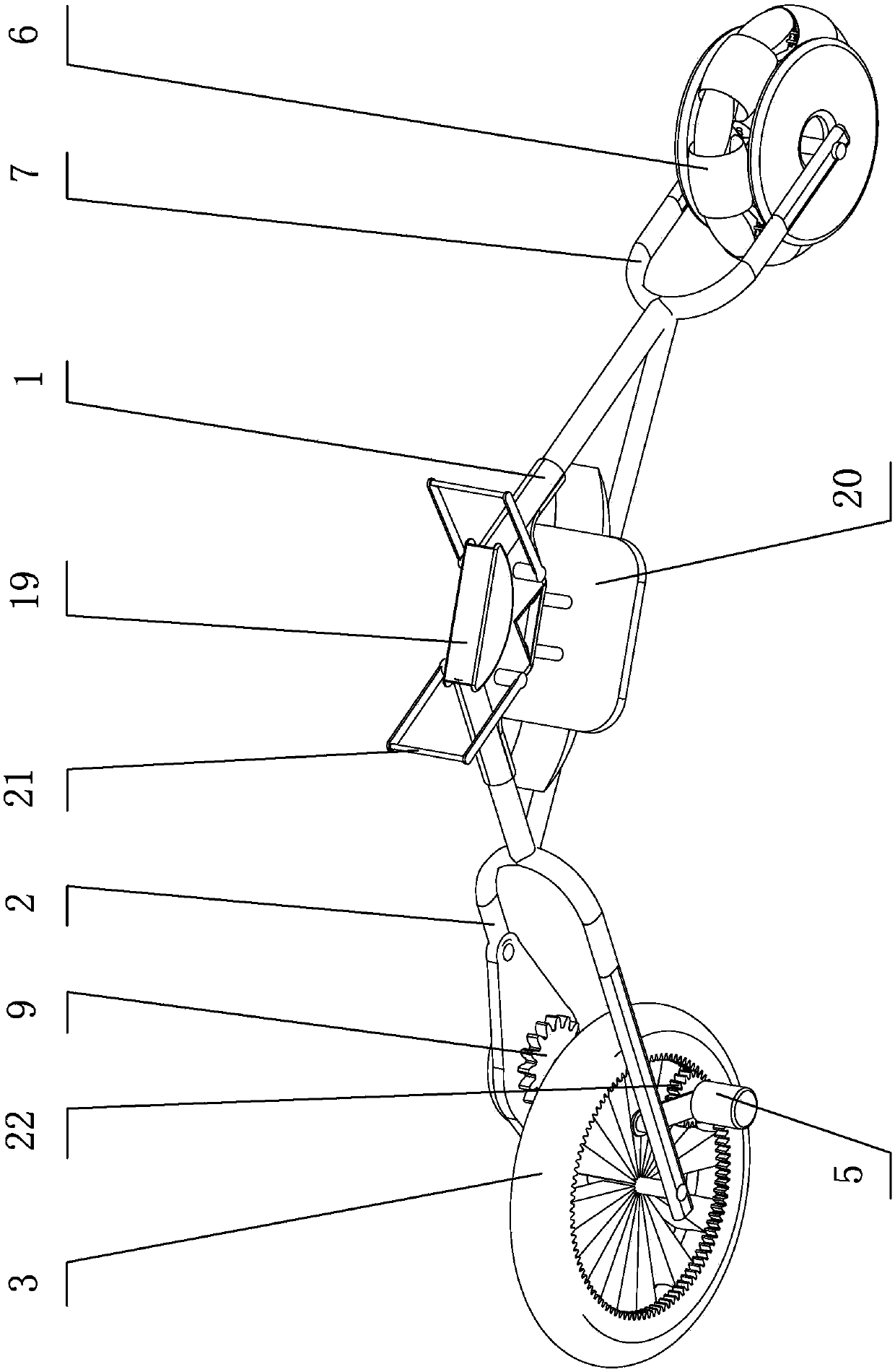

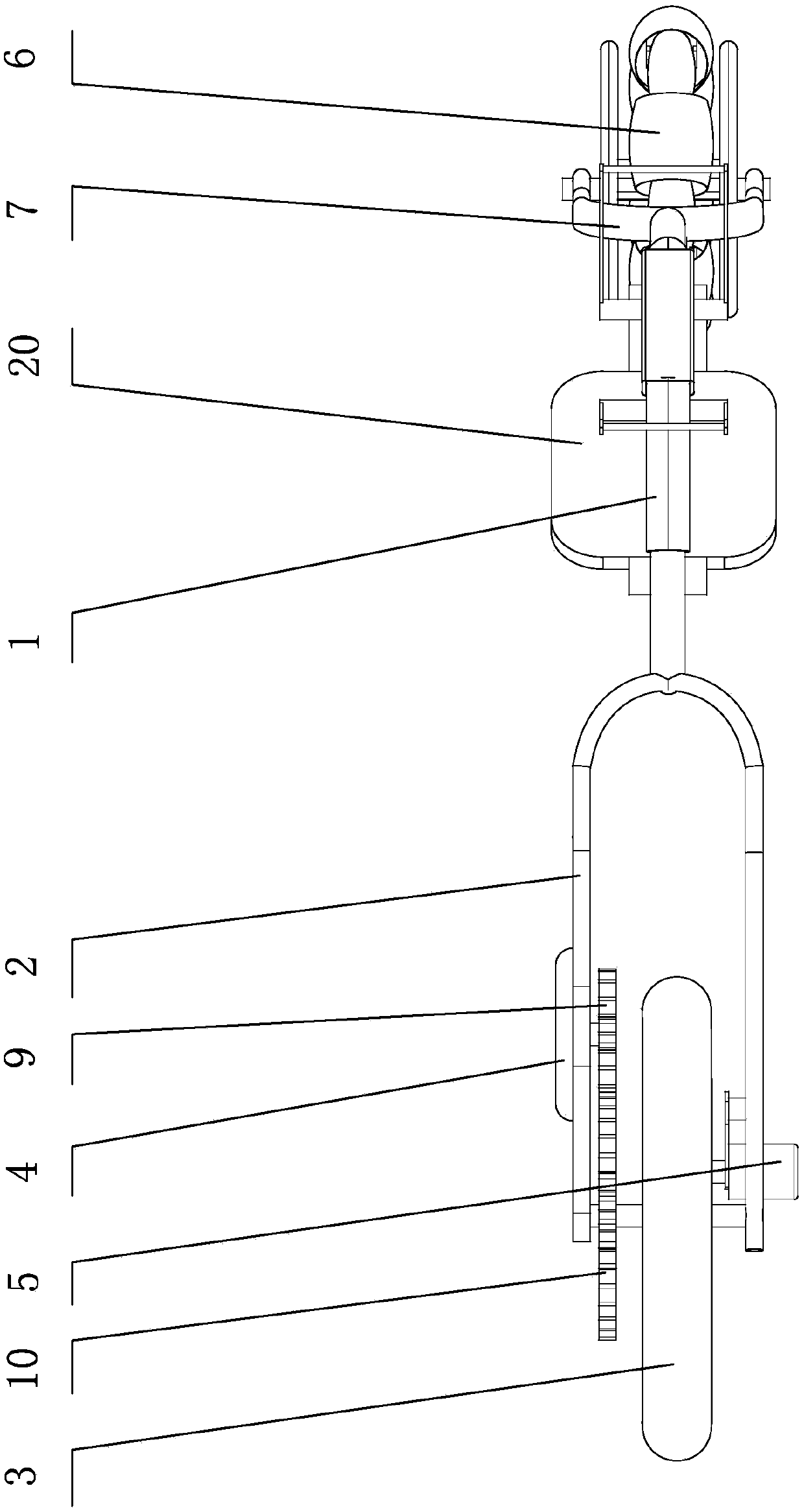

Omnidirectional-wheel-steered handlebar-free self-balancing bicycle

ActiveCN107554663ARealize automatic turningThere is no inner wheel difference problemSteering deviceWheelsDrive wheelGear drive

The invention discloses an omnidirectional-wheel-steered handlebar-free self-balancing bicycle. The omnidirectional-wheel-steered handlebar-free self-balancing bicycle comprises a bicycle frame, a longitudinal travelling device and a horizontal turning device. The longitudinal travelling device comprises a front driving wheel installed at a front bicycle fork of the bicycle frame. The front bicycle fork is provided with a pancake motor for driving the front driving wheel to be rotated through a travelling gear drive mechanism. The front bicycle fork is further provided with a coder for detecting rotational state of the front driving wheel. The horizontal turning device comprises a single-row omnidirectional wheel installed at a rear bicycle fork of the bicycle frame. The single-row omnidirectional wheel comprises section wheels uniformly distributed on the circumference of a wheel hub and rotated horizontally, and each section wheel is connected to be synchronously rotated by a horizontal gear rotation mechanism. The wheel hub is provided with a friction wheel which drives one section wheel to be rotated through a friction force. The driving force of the friction wheel is a turningmotor installed on the wheel hub. In the omnidirectional-wheel-steered handlebar-free self-balancing bicycle, the horizontal velocity vector of the single-row omnidirectional wheel is combined with the longitudinal velocity vector generated by the front driving wheel, so the automatic turning of the handlebar-free bicycle can be realized, and the difference of radius between inner wheels does notexist in the turning method.

Owner:GUILIN UNIV OF ELECTRONIC TECH

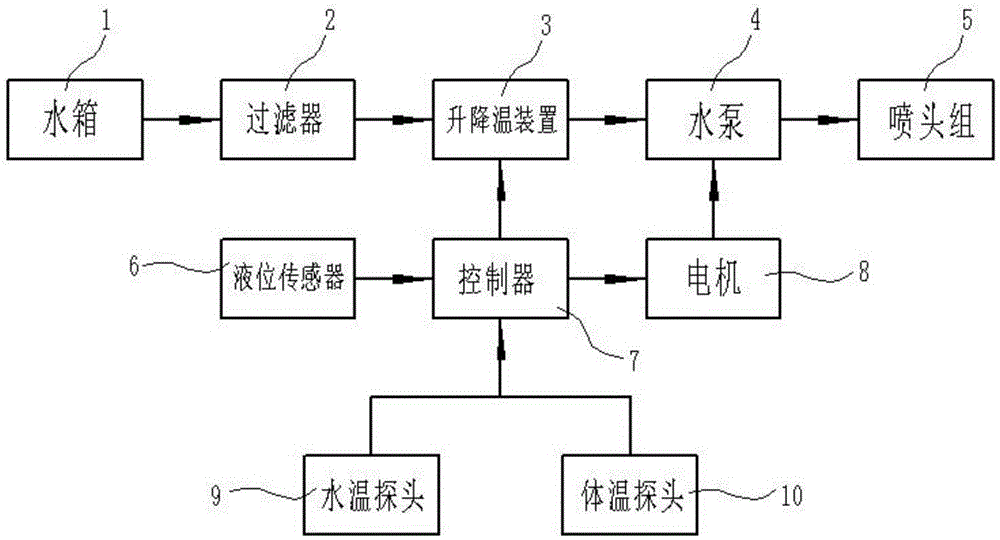

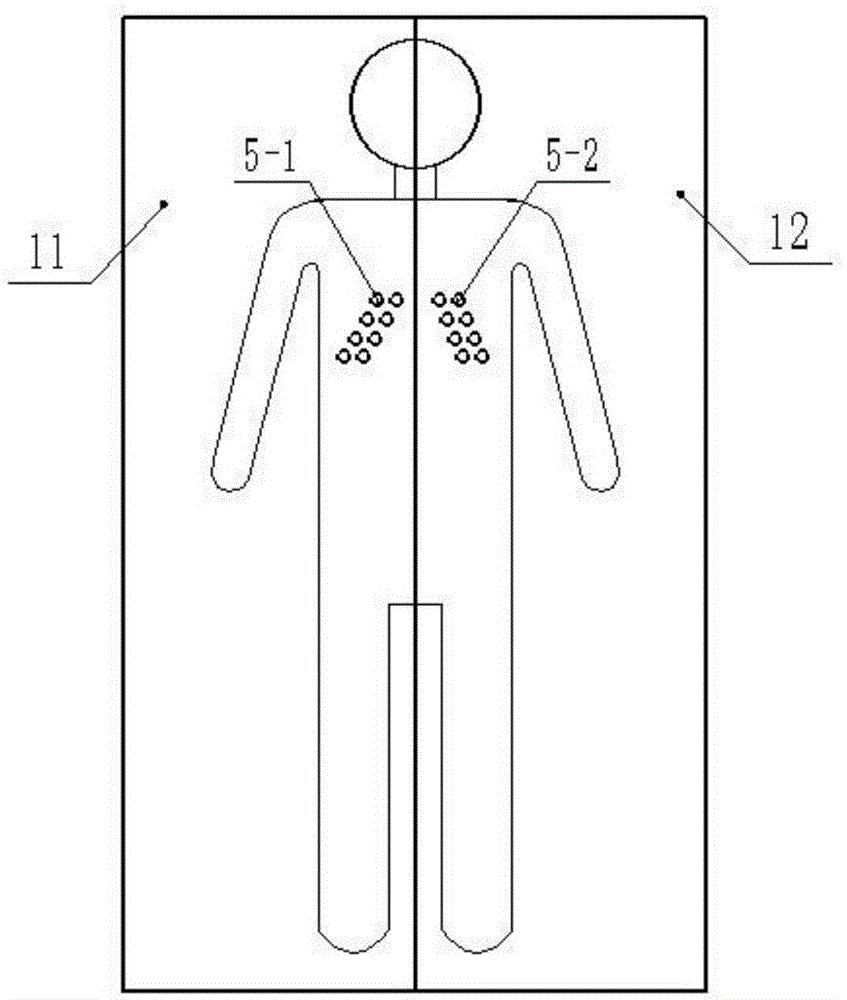

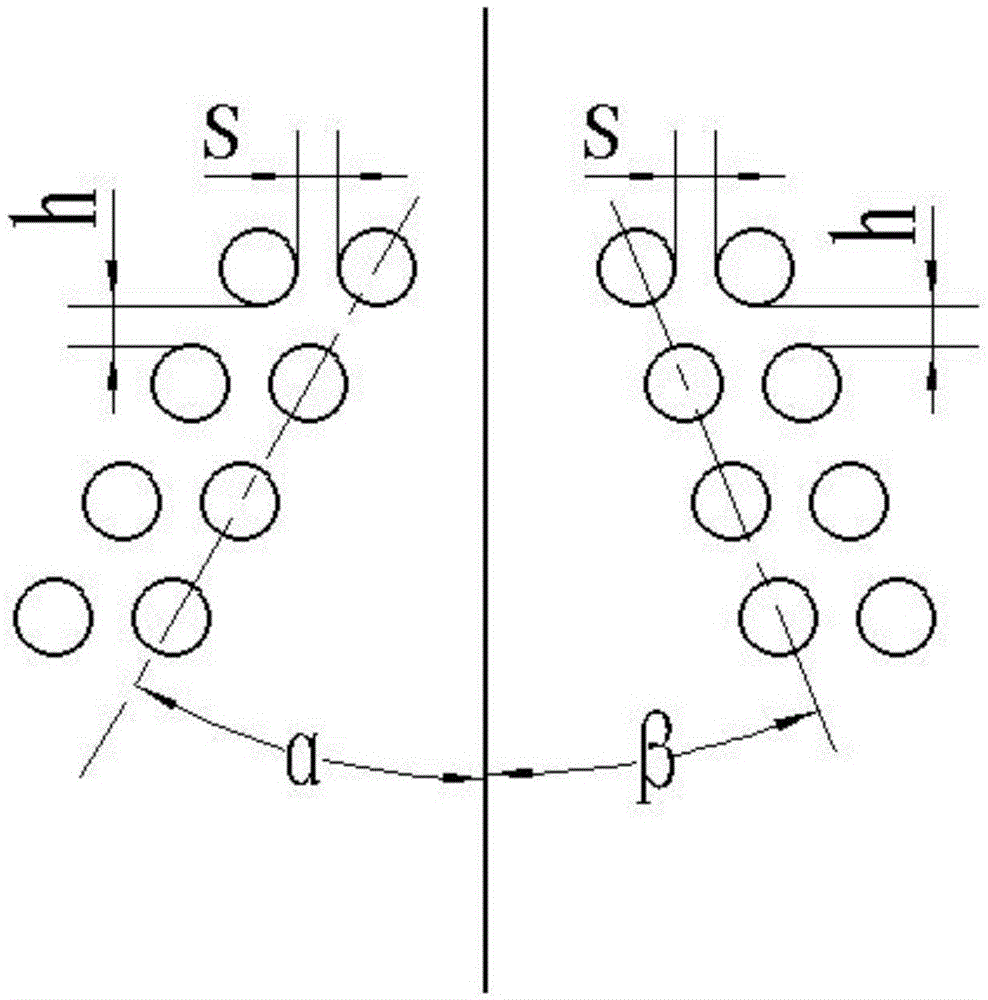

Multifunctional water bed

InactiveCN105596161AAchieve recyclingSave waterDiagnosticsChiropractic devicesPulmonary infectionWater discharge

The invention discloses a multifunctional water bed. The multifunctional water bed comprises a sleeve bag, a water tank, a heater, a water pump, a nozzle group, a controller, a motor and a temperature probe, wherein the sleeve bag is longitudinally separated into a left sleeve bag and a right sleeve bag; the temperature probe comprises a water temperature probe and a body temperature probe; a water discharging hole of the water tank is connected with the heater through a filter; the heater is connected with an inlet of the water pump; the controller is connected with the motor and the heater; the motor is connected with the water pump; the controller is connected with the water temperature probe and the body temperature probe respectively. With the adoption of the multifunctional water bed, a function that a patient can turn over automatically is realized; meanwhile, an automatic back percussion function from bottom to top and from inside to outside of a patient after a thoracic surgery and pulmonary infection is also realized, so that the labor intensity of nurses is greatly alleviated; meanwhile, the multifunctional water bed is a cooling water bed for a patient with high fever and is a heat-conducting treatment water bed, and has an adjunctive treatment effect on the patient.

Owner:卢雯 +1

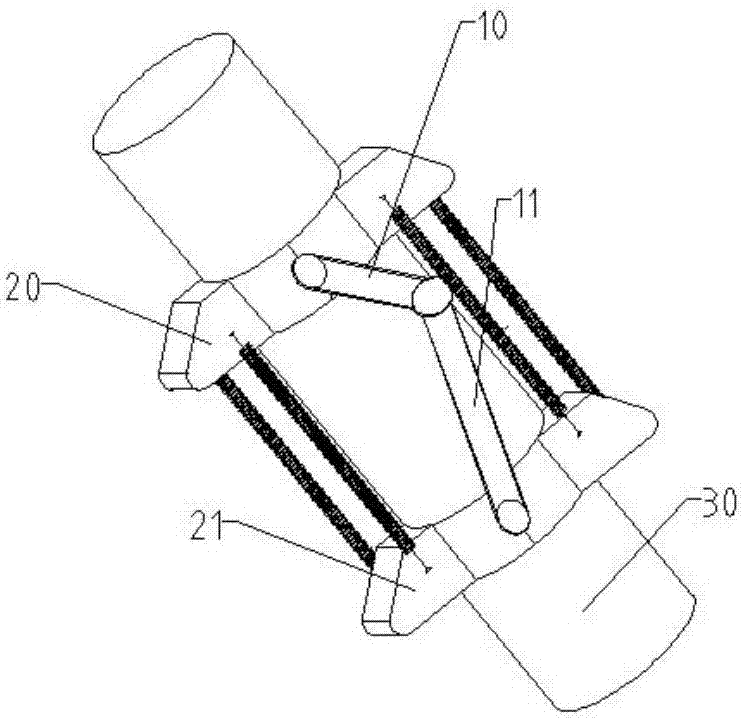

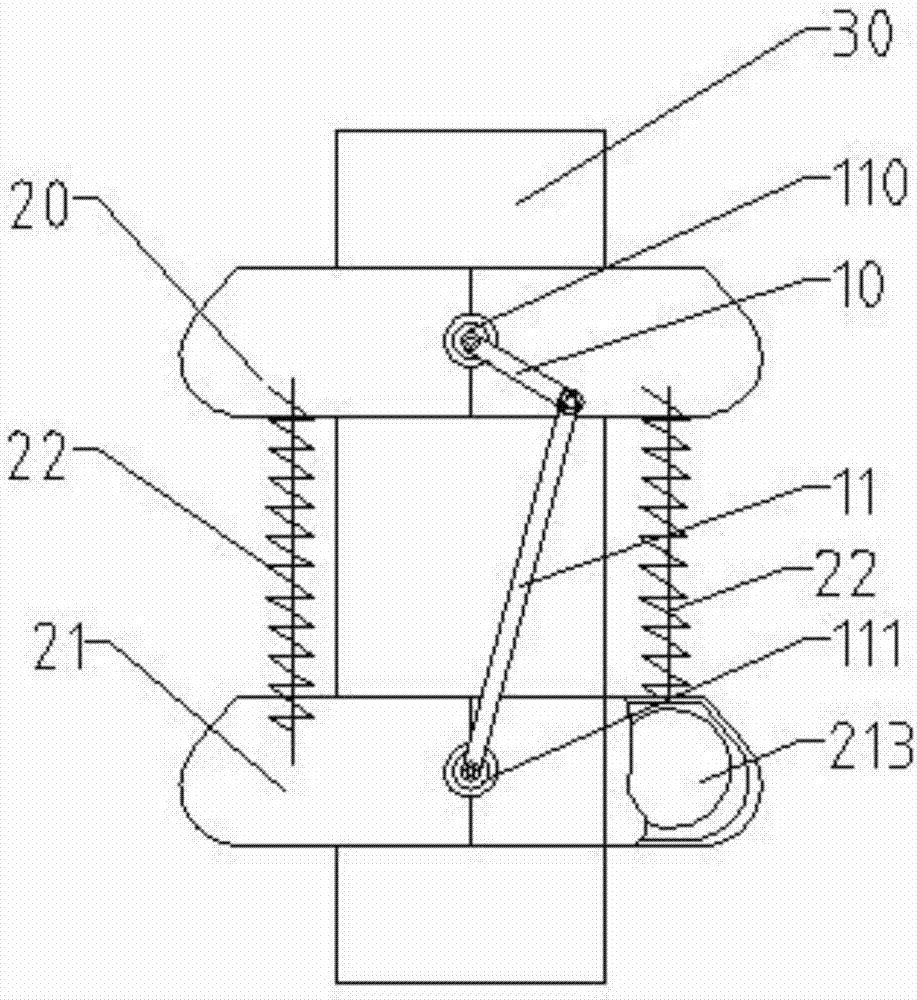

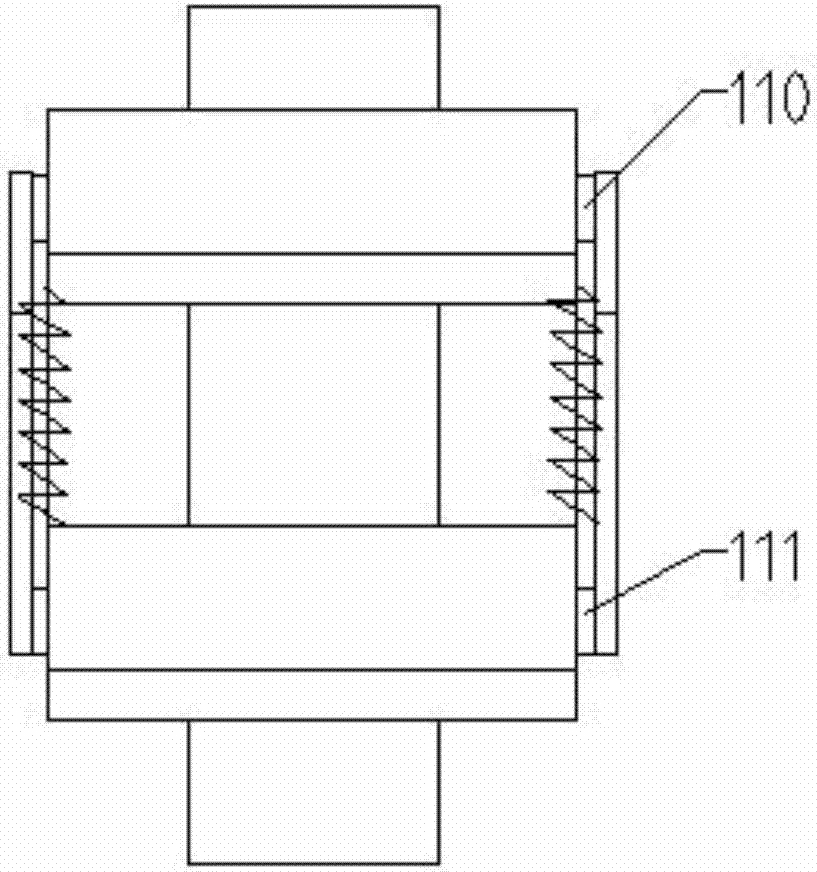

Worm type robot

The invention discloses a worm type robot. The robot comprises self-locking sleeve pair, self-locking balls, and a crank linkage mechanism, wherein the self-locking sleeve pair comprise an upper self-locking sleeve and a lower self-locking sleeve, the upper self-locking sleeve and the lower self-locking sleeve are both provided with through holes for crawling on a cylindrical object, and both ends of the upper self-locking sleeve and the lower self-locking sleeve are provided with a trapezoidal arc structure; the self-locking balls are arranged in both the trapezoidal arc structures and a cavity formed by the upper self-locking sleeve and the lower self-locking sleeve, the diameter of each self-locking ball is greater than the top edge length of each trapezoidal arc structure, and the diameter of the self-locking sphere is less than the bottom length of each trapezoidal arc structure, and the self-locking balls have large enough friction coefficient to provide adequate friction to achieve the self-locking; one end of the crank linkage mechanism is connected in a rotary mode with the upper self-locking sleeve, and the other end is connected in a rotary mode with the lower self-locking sleeve. The worm type robot can achieve the crawling on a complex cylindrical object.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

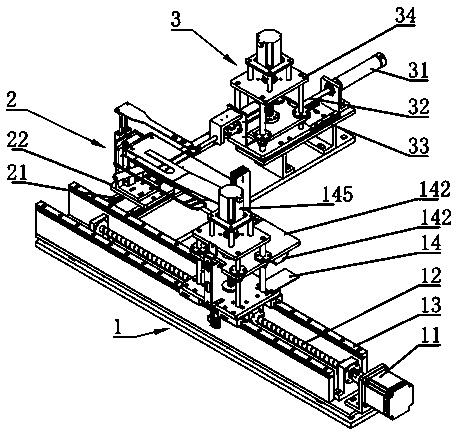

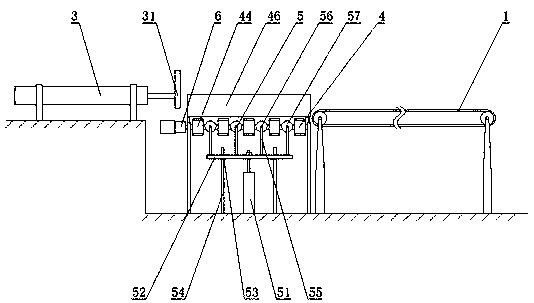

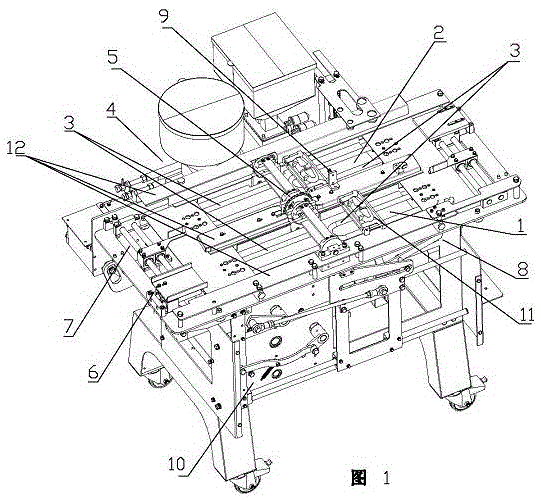

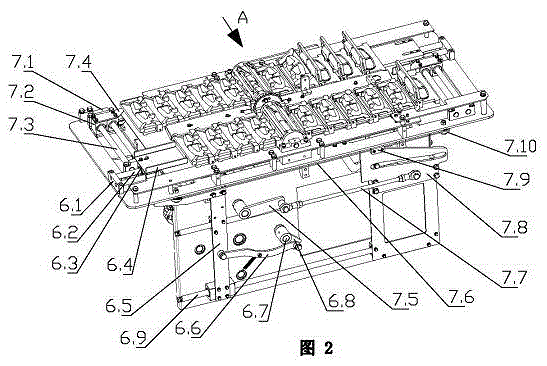

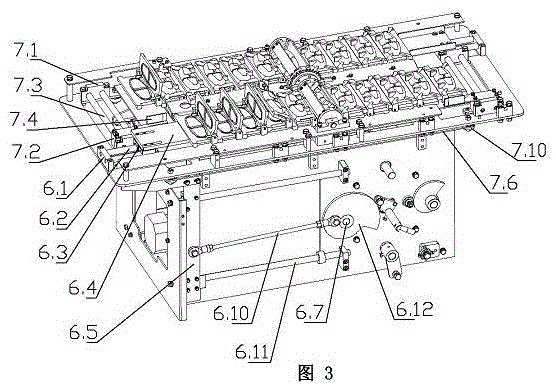

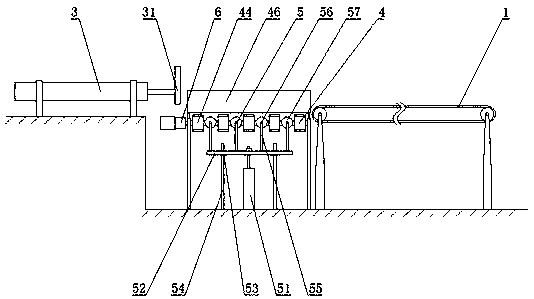

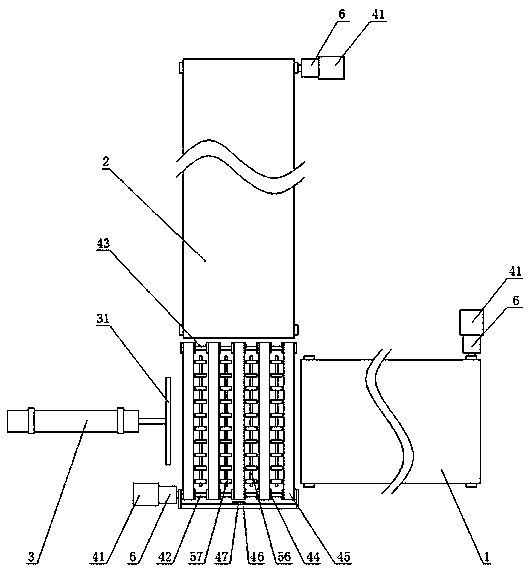

Full-automatic rolling device of egg roll making machine

InactiveCN104223183AEasy to operateReduce labor intensityFood shapingFood preparationEngineeringBall screw

The invention provides a full-automatic rolling device of an egg roll making machine. The full-automatic rolling device at least comprises a rolling and turning assembly, a turning platform assembly and a secondary turning assembly, wherein the rolling and turning assembly comprises a stepping servo motor, a ball screw transmission device which is connected with an output shaft of the stepping servo motor, a horizontally-arranged linear guide rail and a rolling and turning bracket which is movably arranged on the linear guide rail; the turning platform assembly comprises a stepping servo motor, a ball screw transmission device which is connected with the output shaft of the stepping servo motor, a horizontally-arranged linear guide rail and a rolling platform bracket which is movably arranged on the linear guide rail; and the secondary turning assembly comprises a pen-shaped air cylinder, a transmission device which is connected with the output shaft of the pen-shaped air cylinder, a horizontally-arranged linear guide rail and a secondary turning bracket which is movably arranged on the linear guide rail. According to the egg roll making machine, an improved turning fork is adopted and the turning of egg rolls can be completely and mechanically finished; and the full-automatic rolling device of the egg roll making machine, which is simple to operate and high in efficiency, is provided.

Owner:胡海潮

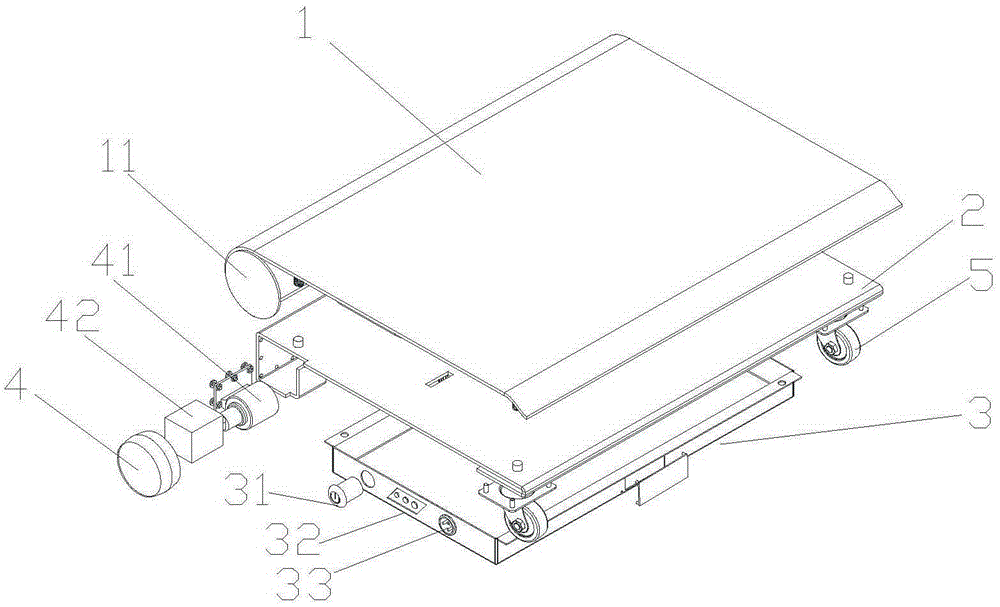

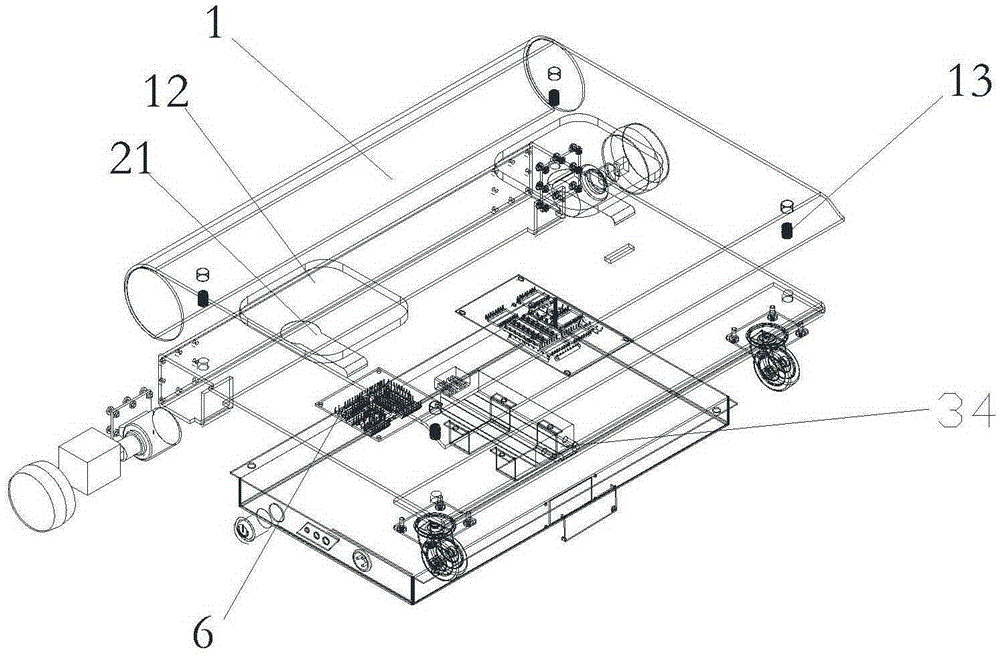

Flat scooter

InactiveCN105329380ASolve the stop problemClearly distinguish pressure changesCyclesControl signalEngineering

The invention discloses a flat scooter. The scooter comprises upper shells which can be used as pedals, lower shells arranged at the bottoms of the upper shells and a separator arranged between the upper shells and the lower shells; four sliding wheels are arranged on the separator; two pressure sensors for sensing the pressure of a human body are arranged between the upper shells and the separator, and are arranged on positions of the upper shells corresponding to the left foot and the right foot of a user; the pressure sensors are arranged on control panels on the lower shells in a connecting manner; the control panels can be used for receiving pressure signals of the pressure sensors and transforming the pressure signals to control signals, and are connected with sliding wheels to control startup of the sliding wheels; when the user steps on the upper shells, the pressure sensors are used for transmitting pressure change signals of left and right feet to the control panels, and the control panels are used for controlling instant stop or turning of the sliding wheels. The flat scooter can be instantly stopped since the pressure sensors are respectively arranged on left and right feet of the user.

Owner:刁会芳

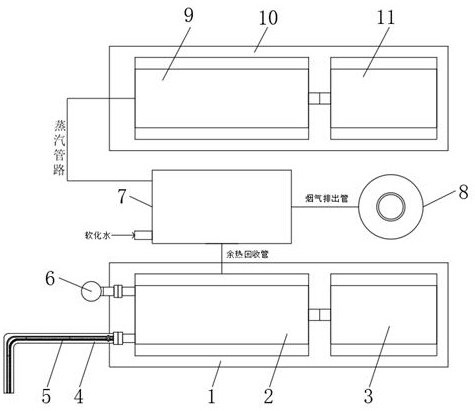

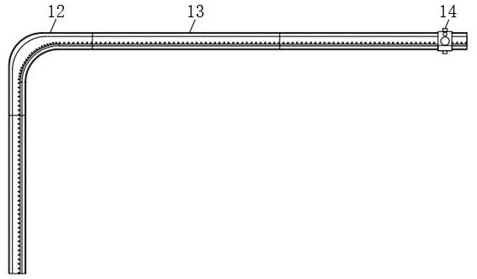

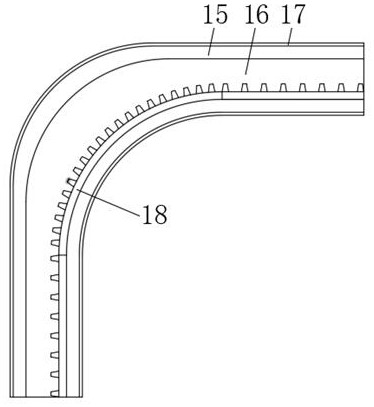

Natural gas power generation system with natural gas pipeline leakage monitoring effect

InactiveCN113739073AReduce frictionReduce corrosionPipe supportsPipeline systemsThermodynamicsProcess engineering

The invention discloses a natural gas power generation system with the natural gas pipeline leakage monitoring effect. The system comprises a first power generation base plate and a second power generation base plate, a gas turbine is fixedly installed at one side of the top of the first power generation base plate, and a gas generator is fixedly installed at the other side of the top of the first power generation base plate. The output end of the gas turbine is fixedly connected with the input end of the gas generator, the gas inlet end of the first power generation base plate is fixedly connected with a gas pipeline, and the top of the gas pipeline is provided with a gas leakage detection guide assembly. According to the natural gas power generation system with the natural gas pipeline leakage monitoring effect, a gas sensor detects whether gas leakage occurs in the gas pipeline while moving, so that the natural gas power generation system has the pipeline gas leakage self-checking effect, and the situation of gas leakage can be found in time; and the waste caused by natural gas leakage is reduced, and the potential safety hazard of gas leakage is avoided.

Owner:陈壮

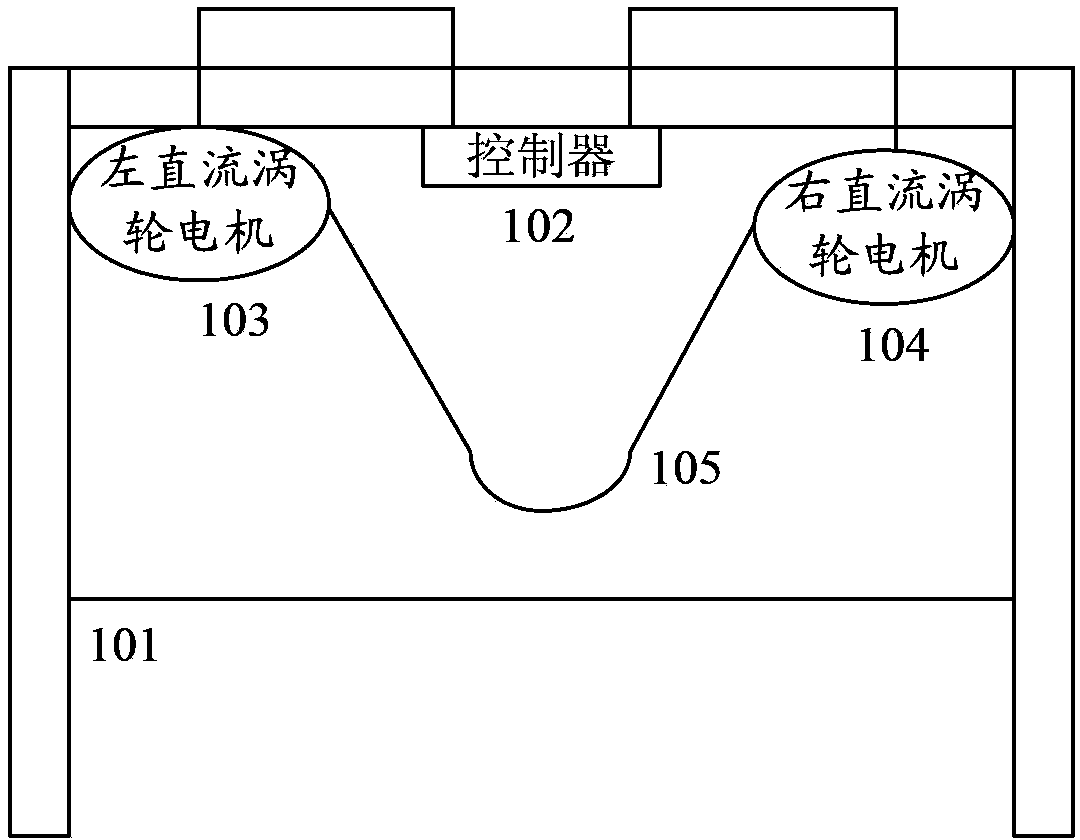

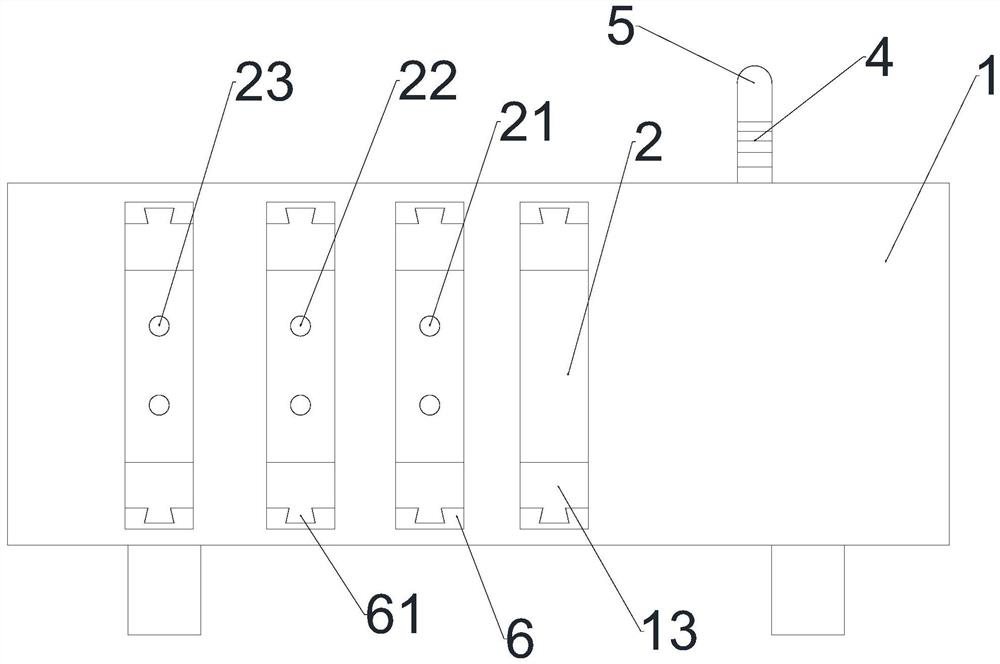

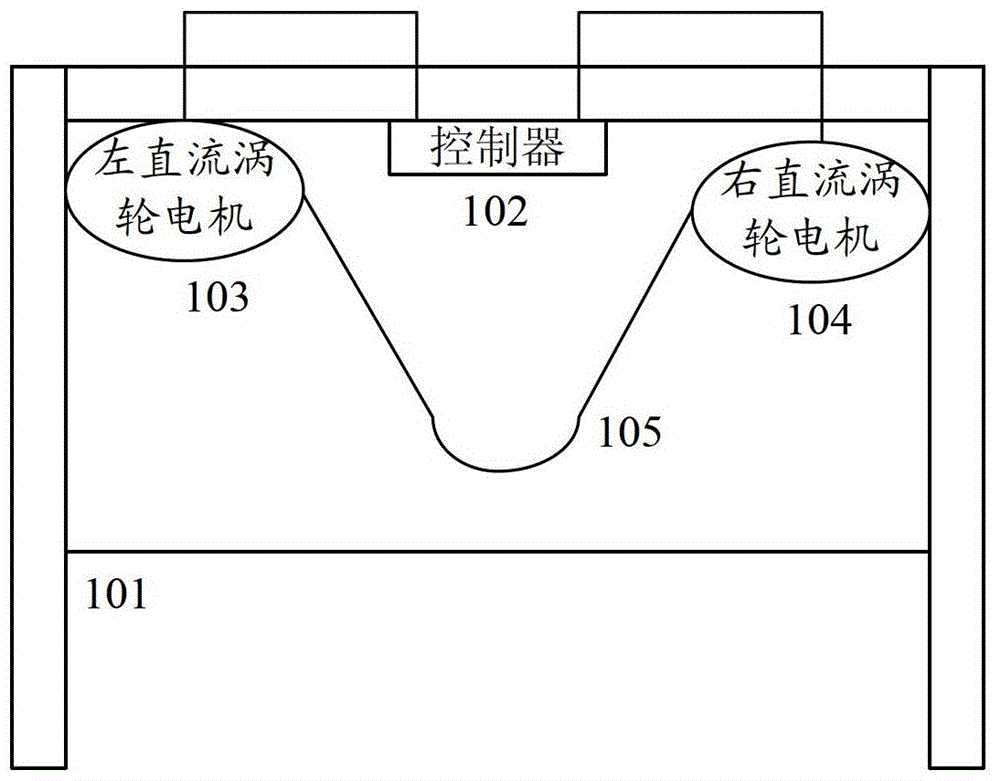

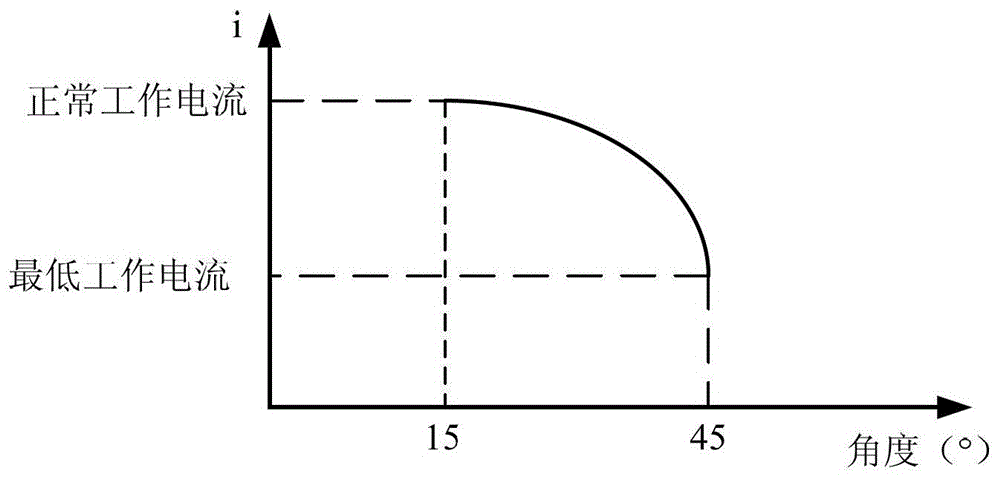

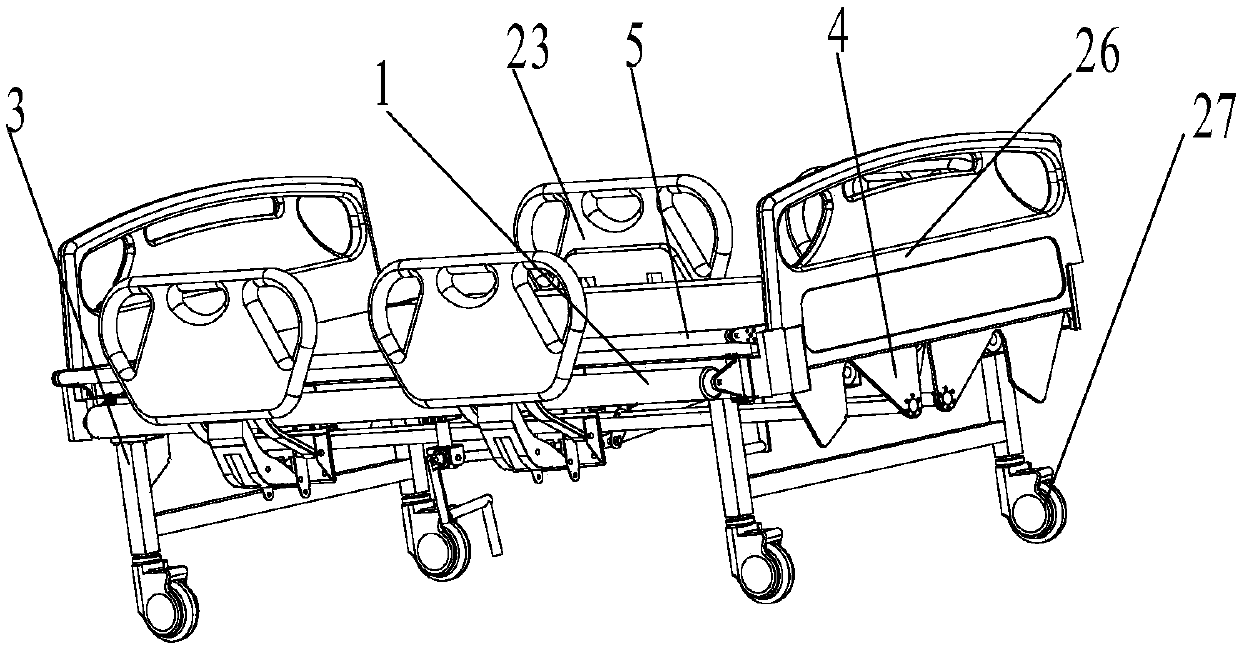

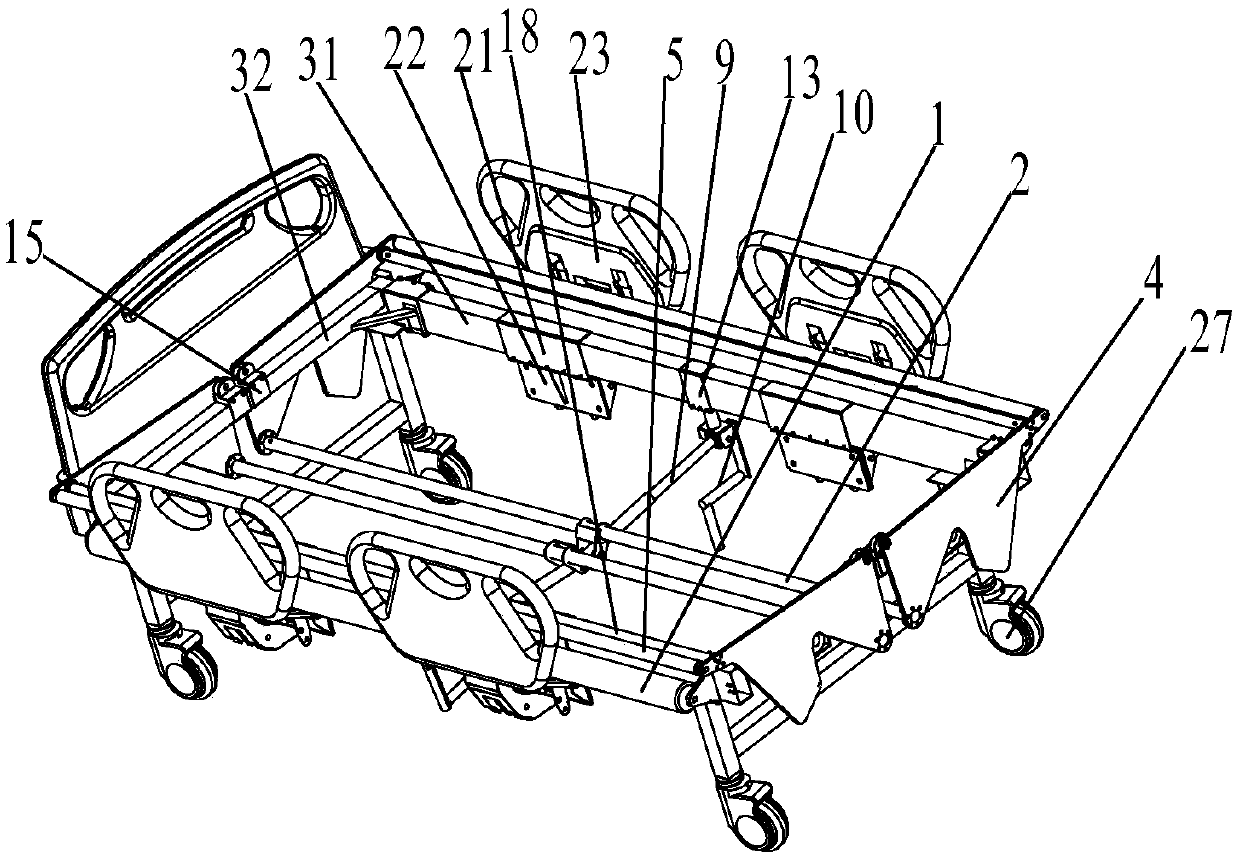

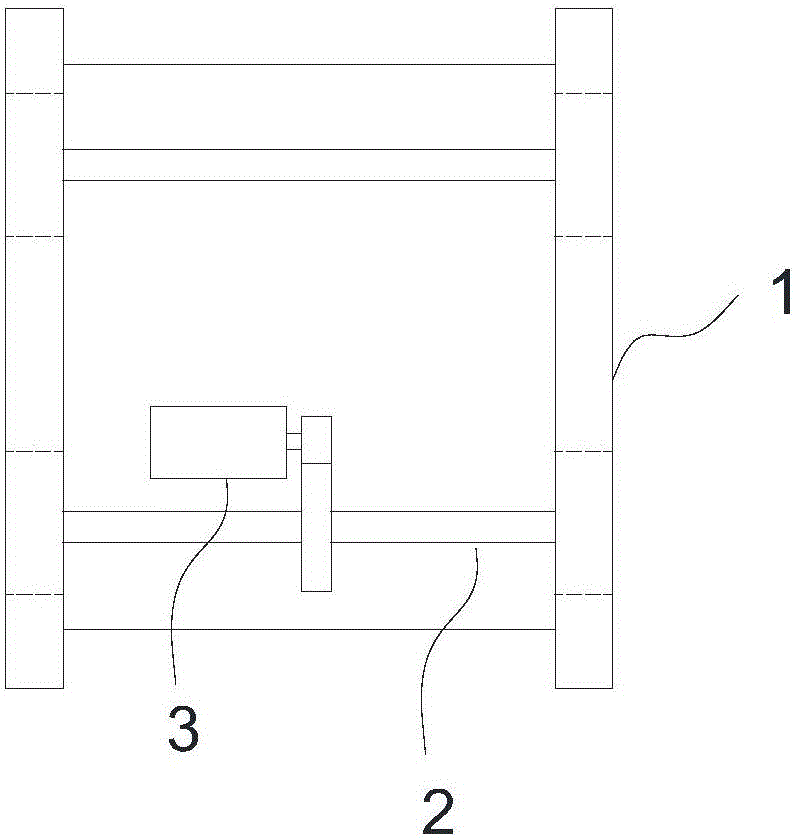

Multifunctional electric stryker frame

ActiveCN103876901ARealize automatic turningAutomatic turn over hasNursing bedsElectricityElectric machine

The invention provides a multifunctional electric stryker frame, and is applicable to the technical field of electronics. The multifunctional electric stryker frame comprises a rack, a controller, a left direct-current turbine motor, a right direct-current turbine motor and a hanging strap, wherein the controller is fixed on the top of the rack, and is electrically connected with the left direct-current turbine motor and the right direct-current turbine motor respectively; rotation of the left direct-current turbine motor and rotation of the right direct-current turbine motor are controlled by the controller; the controller is used for receiving a leftward turning-over command inputted by a user, inputs forward current to the left direct-current turbine motor so as to control forward rotation of the left direct-current turbine motor, and inputs reverse current to the right direct-current turbine motor by delaying two periods so as to control reverse rotation of the right direct-current turbine motor; and the absolute value of the forward current is equal to that of the reverse current. According to the technical scheme provided by a concrete implementing mode of the invention, the multifunctional electric stryker frame has an automatic turning-over function.

Owner:SHENZHEN LIFE BRAVE MECHANICAL TECH +1

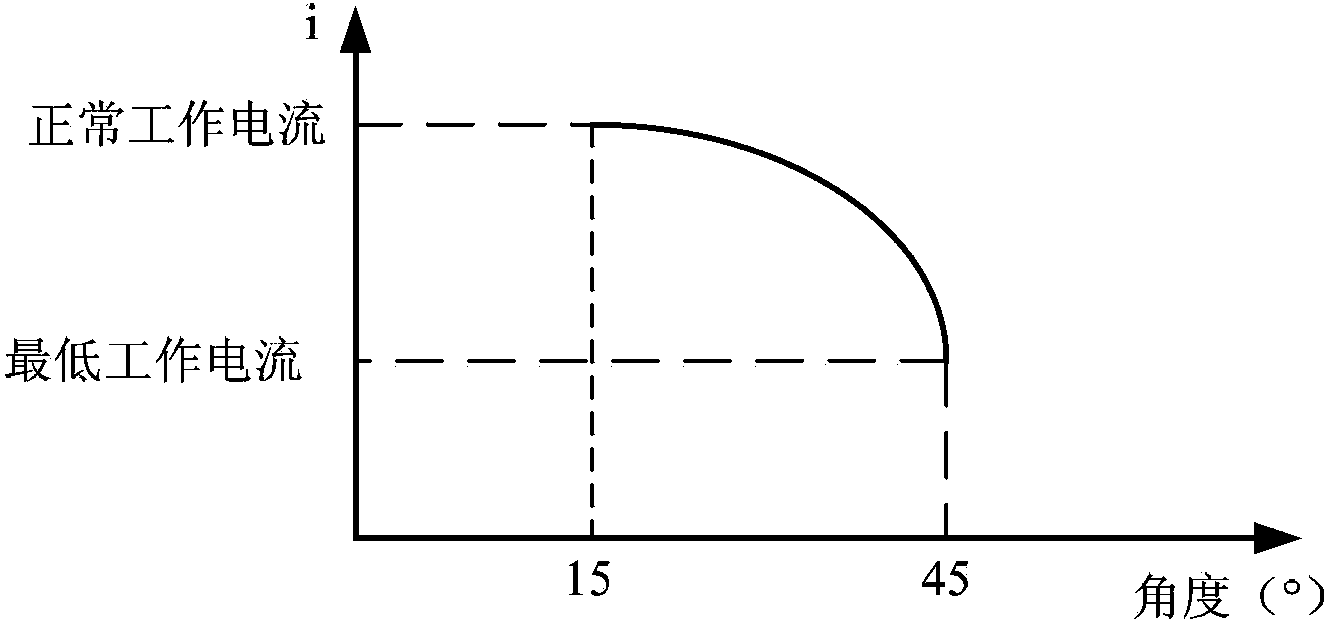

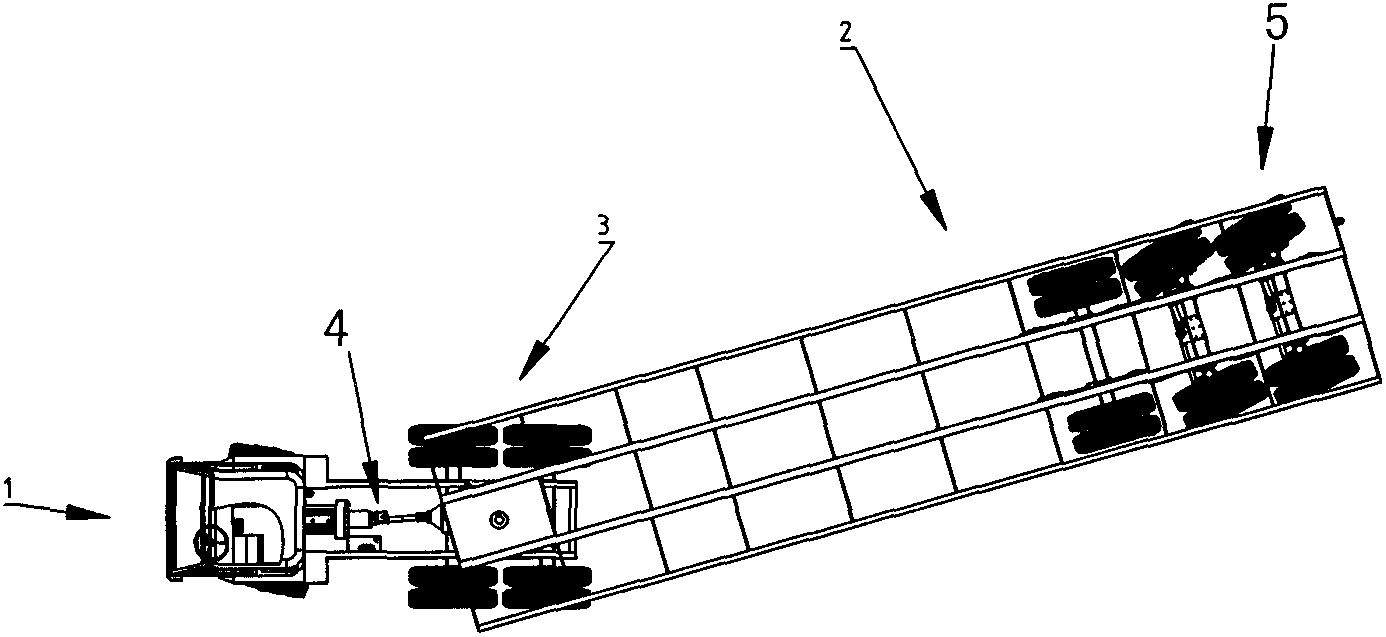

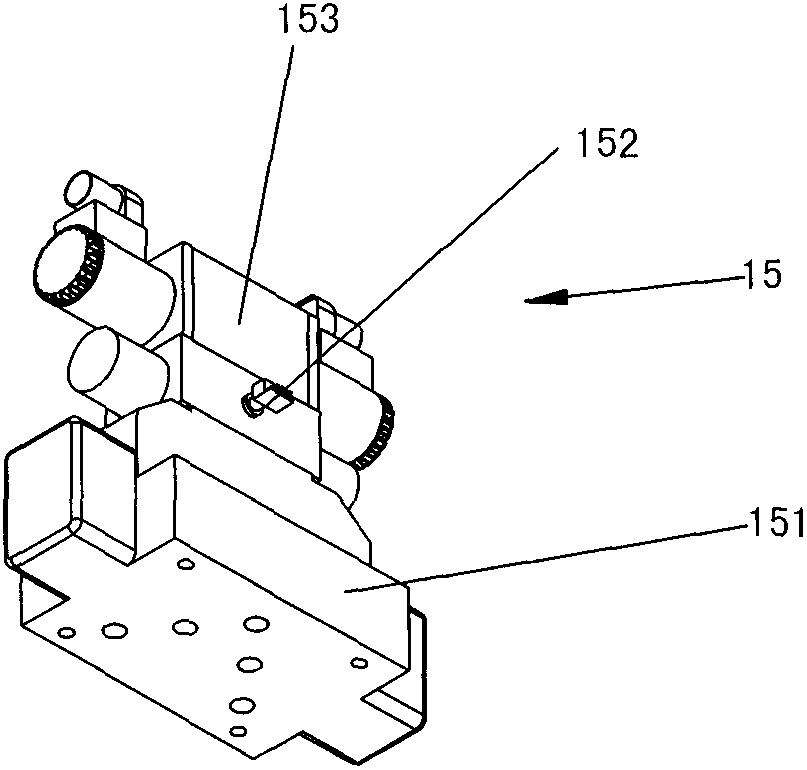

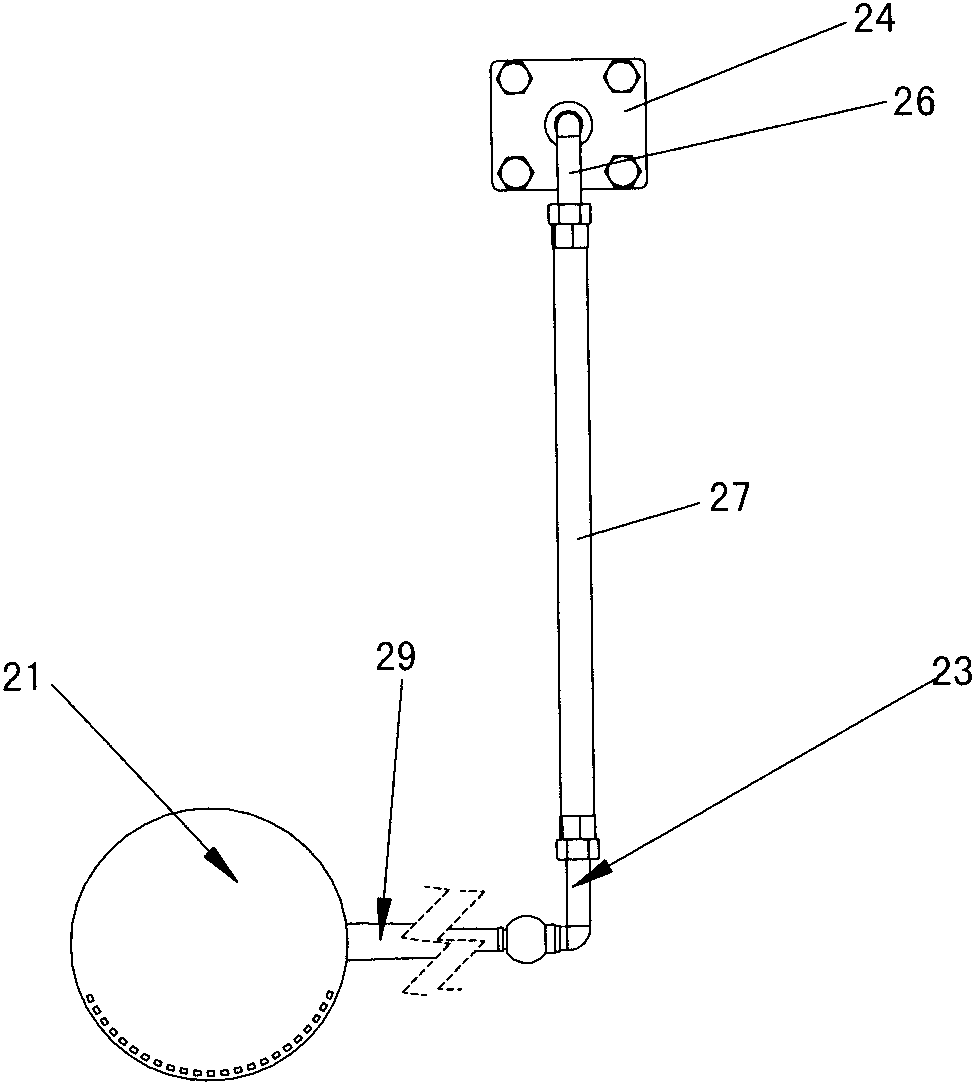

Three-axle trailer steering system

InactiveCN102320329ARealize automatic turningSimple structureElectrical steeringTrailer steeringAutomatic controlSolenoid valve

The invention discloses a three-axle trailer steering system, comprising a hydraulic system and a steering mechanism, wherein the hydraulic system controls the steering mechanism, and the steering mechanism controls wheels of a three-axle trailer to swerve. The three-axle trailer steering system further comprises a sensing system and a control system, wherein the sensing system is used for sensing a tractor swerving angle, the sensing system is mounted on the steering mechanism, and the sensing system is electrically connected with the control system; the control system is used for receiving a signal of the sensing system and controlling the hydraulic system, and the control system comprises a central controller. The three-axle trailer steering system has simple structure, and can realizeautomatic steering of the three-axle trailer. The three-axle trailer steering system has the following benefits that: 1, a PLC (Programmable Logic Controller) technology is used in the trailer, and automatic control is realized by combination with a hydraulic solenoid valve; 2, two groups of steering axle serial oil circuits are provided for realizing synchronization of two groups of steering axles; 3, an axle head of each steering axle is provided with a hinge, and a thrust wheel can rotate for certain degrees around a hinge pin, so that transverse dragging in a steering process is reduced; 4, manual operations are configured in a driving cab, which facilitates operations of meeting other cars, backing up, moving to other sites, and the like, for a driver.

Owner:迟树廷

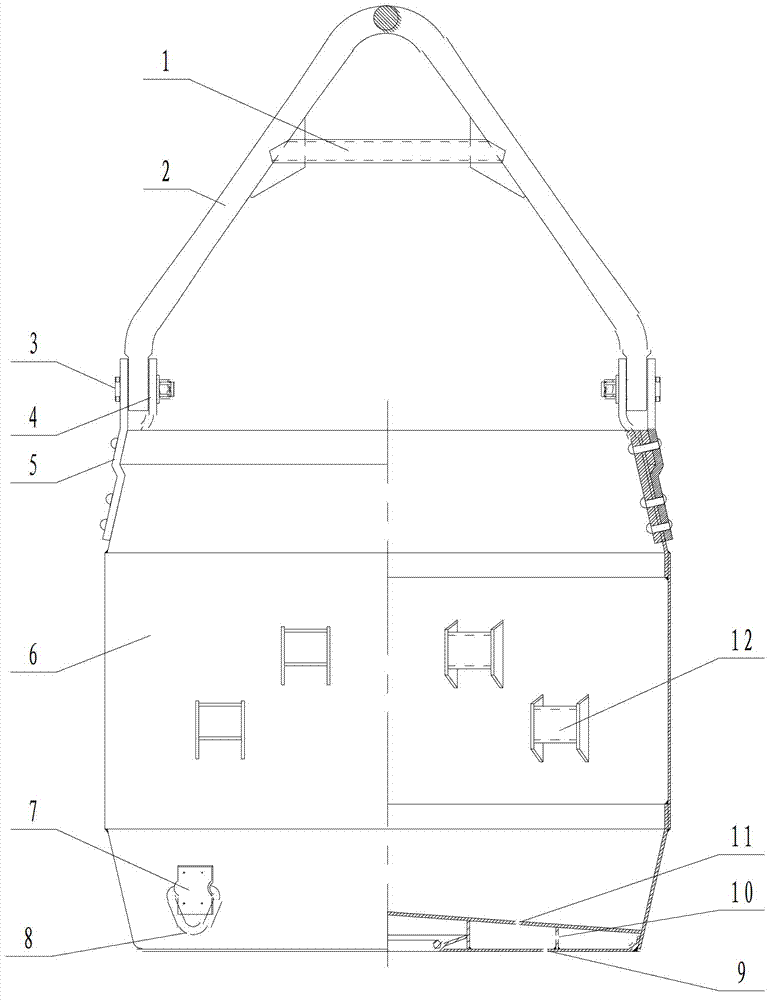

Seat hook type hoist bucket

ActiveCN102923557AFlexible rotationFirmly connectedLoad-engaging elementsShaft liningLifting capacityHeadframe

The invention relates to a seat hook type hoist bucket, which comprises a bucket beam, hinge pins, an inner earring, an outer earring, a bucket body and a double-layer bucket bottom, wherein the bucket beam is arranged on the top of the hoist bucket and movably fixed between the inner earring and the outer earring through the hinge pins which penetrate through the inner earring arranged on the inner side of the top of the bucket body and the outer earring arranged on the outer side of the top of the bucket body; the bottom of the bucket body is provided with double layers; and the double-layer bucket bottom is matched with a seat hook device arranged on a gangue turnover platform of a sinking headframe, so that automatic gangue turnover of the bucket is realized. The volume value of the bucket is between 5.5 cubic meters and 8 cubic meters and is acquired with an interval of 0.5 cubic meter. By the seat hook type hoist bucket, the volume of the bucket is increased, gangue lifting capacity in unit time is improved, at the determinate lifting speed, gangue conveying capacity of a shaft project is greatly improved, and the gangue removing time is reduced; and rapid construction of the large-scale mine deep shaft project is guaranteed.

Owner:JCHX MINING MANAGEMENT +1

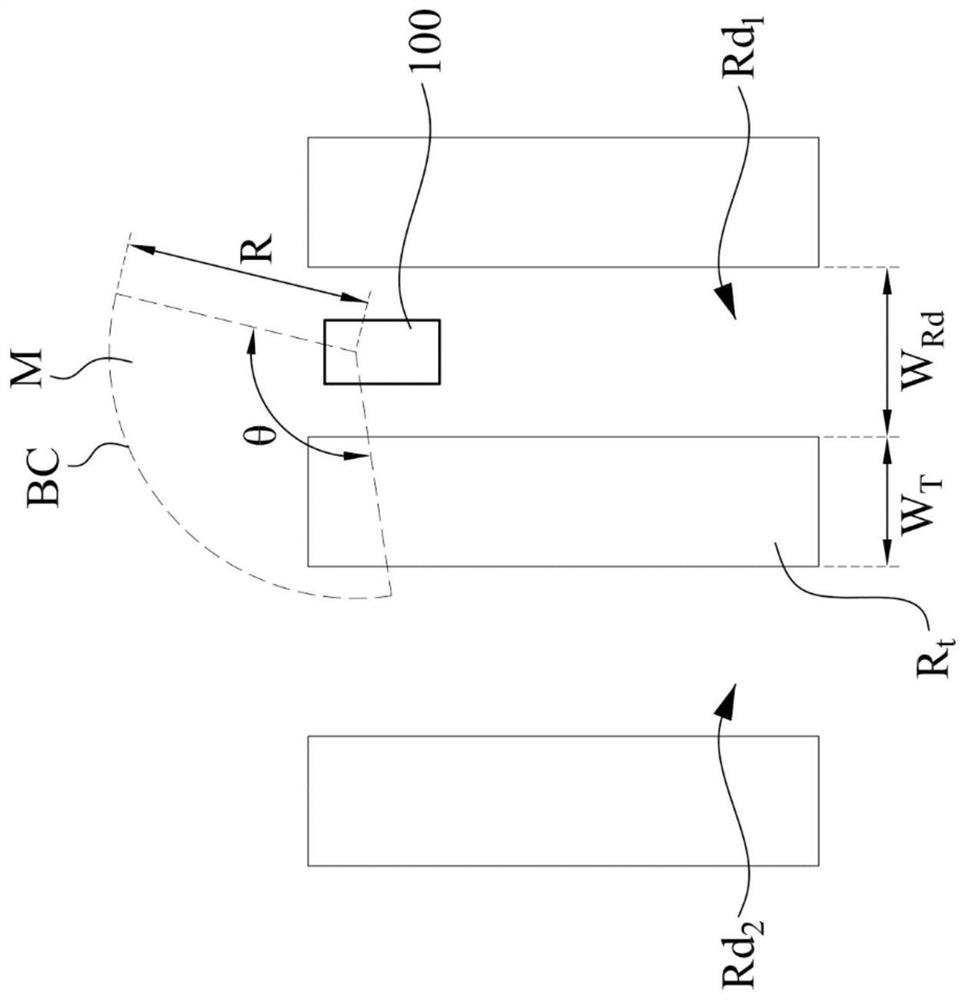

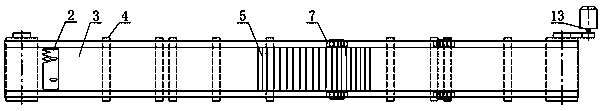

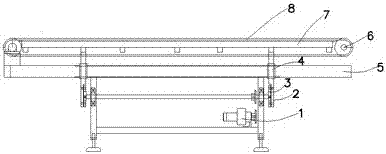

Quarter turn conveying device and working method thereof

ActiveCN110921273ARealize automatic turningSolve the technical problems of inconvenient loading and unloadingConveyorsControl devices for conveyorsElectric machineryIndustrial engineering

The invention discloses a quarter turn conveying device and a working method thereof. The quarter turn conveying device comprises a belt conveyer A and a belt conveyer B, and is characterized in thatthe belt conveyer A and the belt conveyer B are arranged to form an angle of 90 degrees, the intersection of the belt conveyer A and the belt conveyer B is provided with a steering gear, a sliding wheel unit is arranged on the lower side of the steering gear, a push cylinder is arranged on one side of the steering gear, the belt conveyer A, the belt conveyer B and the steering gear are each provided with a motor, the steering gear further comprises a machine frame, a rotating shaft A and a rotating shaft B are rotationally connected with the machine frame, one end of the rotating shaft A is fixedly connected with the output end of the corresponding motor, the rotating shaft A and the rotating shaft B are each sleeved with a plurality of belt wheels at intervals, and a belt is connected between the belt wheels sleeving the rotating shaft A and the belt wheels sleeving the rotating shaft B. The quarter turn conveying device aims to solve the problems that when a plurality of conveying devices are used in cooperation at present, feeding and discharging are not convenient and the conveying devices cannot turn a corner or conveniently adjust the speed.

Owner:山东炎黄工业设计有限公司

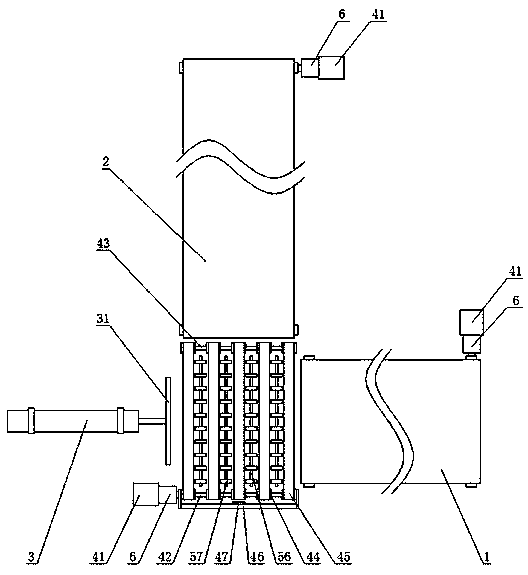

Cake making machine

InactiveCN105532772AFunction as a sliding bearingRealize automatic turningBaking vesselsRoasters/grillsPulp and paper industryInjection device

The invention discloses a cake making machine. The cake making machine comprises a machine frame, cake moulds and a material injection device comprising a material barrel. An inner heating zone and an outer heating zone are arranged on the table top of the machine frame in parallel. A mould turning device is arranged at the middle section of the table top of the machine frame. Two longitudinal mould pushing devices are longitudinally arranged at one group of opposite angles of the table top of the machine frame and are in transmission connection with a longitudinal driving shaft, and two transverse mould pushing devices are transversely arranged at the other group of opposite angles of the table top of the machine frame. A mould closing stopping block is arranged on the table top of the machine frame. A mould opening device comprising a mould opening rocker is further arranged on the machine frame. The mould opening device and the transverse mould pushing devices are both driven by a transverse crank. According to the cake making machine, the cake moulds can be automatically and circularly pushed and automatically turned over; the cake making machine is reasonable in structure and safe to use.

Owner:WUJIN DISTRICT HUTANG HUIFU MACHINERY EQUIP FACTORY

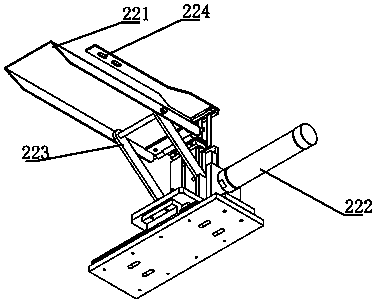

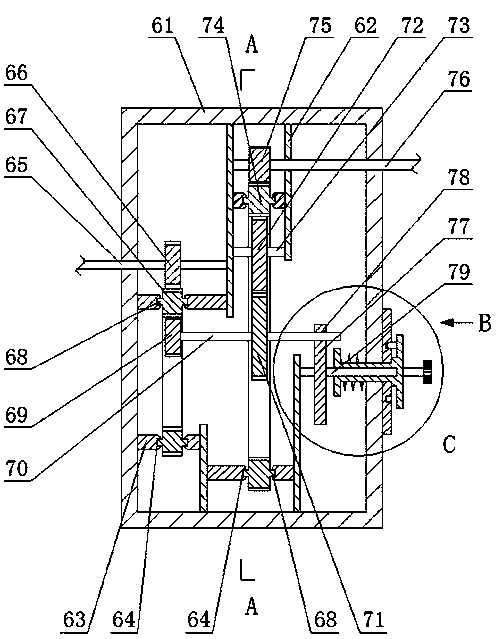

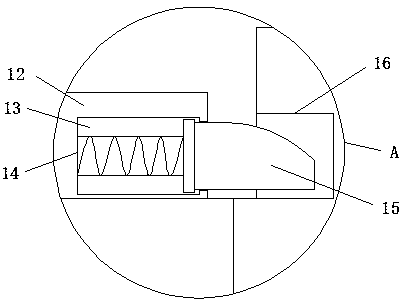

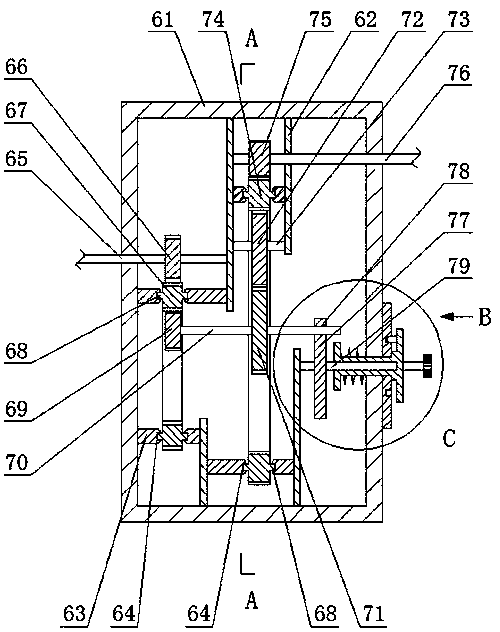

Automatic turning mechanism used for nursing bed

ActiveCN107898577AEasy dockingReduce stressNursing bedsAmbulance serviceHydraulic cylinderButt joint

The invention discloses an automatic turning mechanism used for a nursing bed. The automatic turning mechanism comprises a bottom plate and further comprises an automatic turning mechanism body and abed board lifting mechanism, wherein the automatic turning mechanism body is arranged at the top of the bottom plate, and the bed board lifting mechanism is located in the middle of the automatic turning mechanism body; the automatic turning mechanism body comprises a first supporting plate and a second supporting plate, wherein the first supporting plate and the second supporting plate are weldedto the two sides of the bottom of the bottom plate, a motor is installed on the outer end face of the second supporting plate, a turning support is arranged between the first supporting plate and thesecond supporting plate, and the motor drives the turning support to rotate in the axial direction; a moving opening is formed in the bottom of the turning support and corresponds to the bed board lifting mechanism, an elastic butt joint mechanism is arranged inside the turning support and comprises a butt joint support and a first hydraulic cylinder driving the butt joint support to move in thevertical direction, and strip-shaped sliding grooves are formed in the inner walls of the two sides of the butt joint support respectively. The automatic turning mechanism is reasonable in design layout, achieves the purpose of automatic turning, makes turning safe and stable, helps a patient to recover, and improves the comfort degree for the patient and the using quality of the nursing bed.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

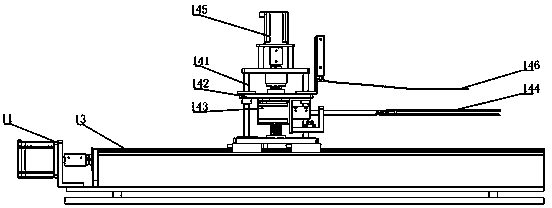

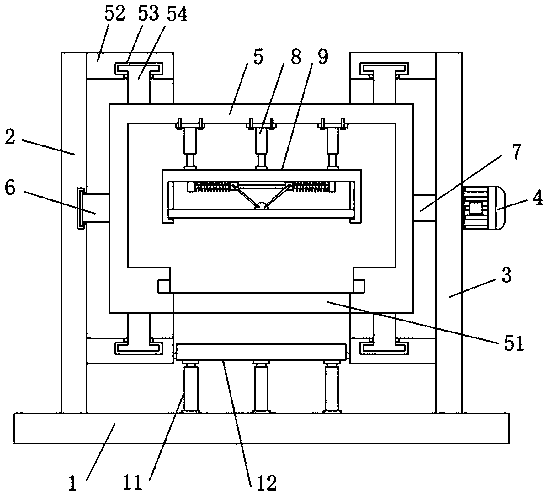

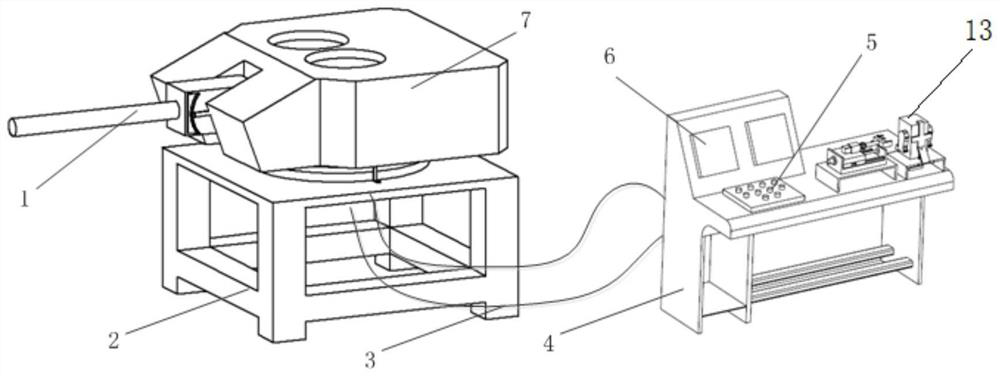

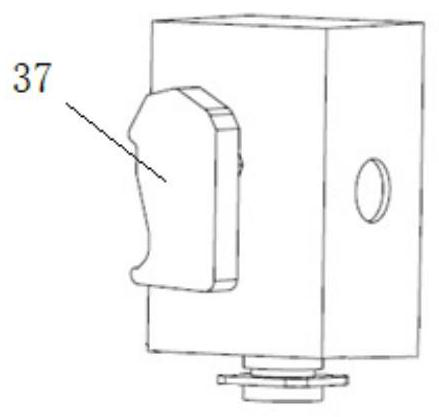

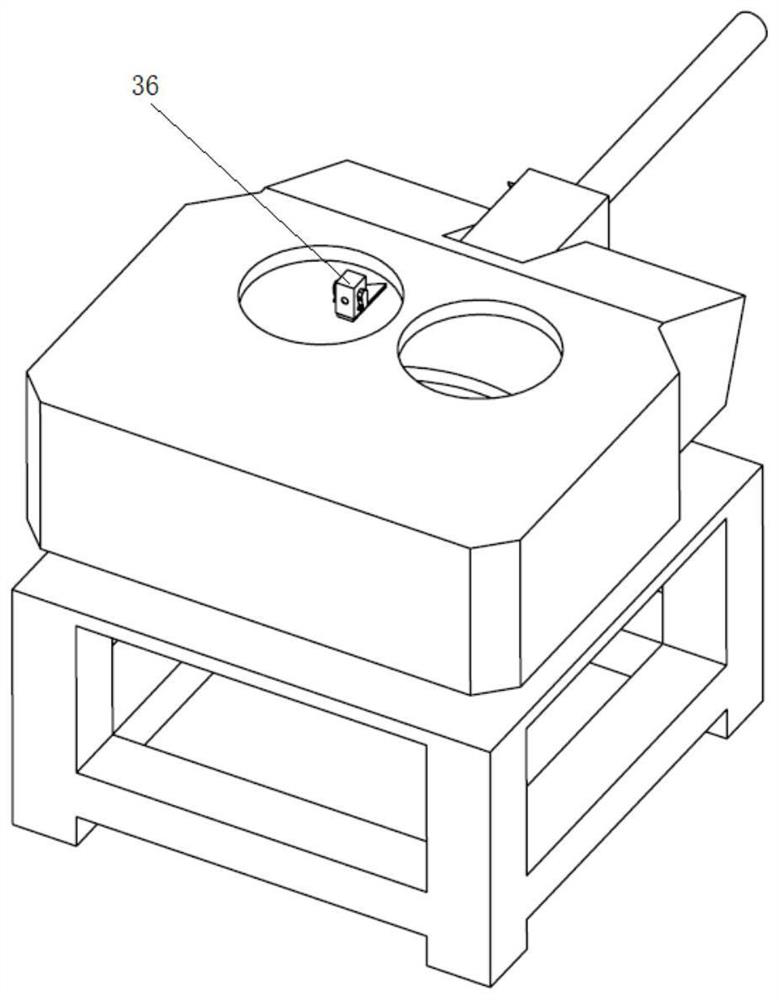

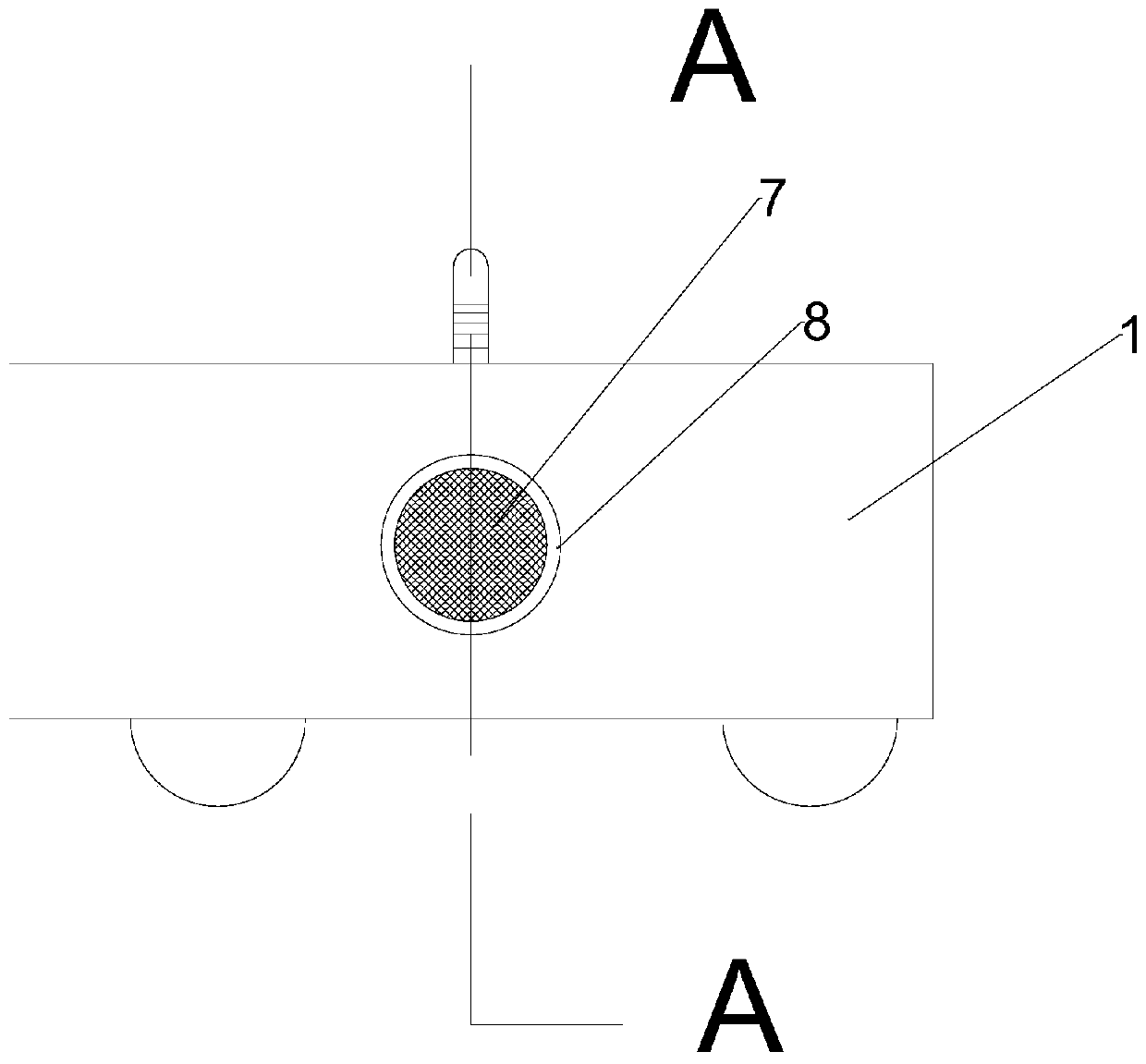

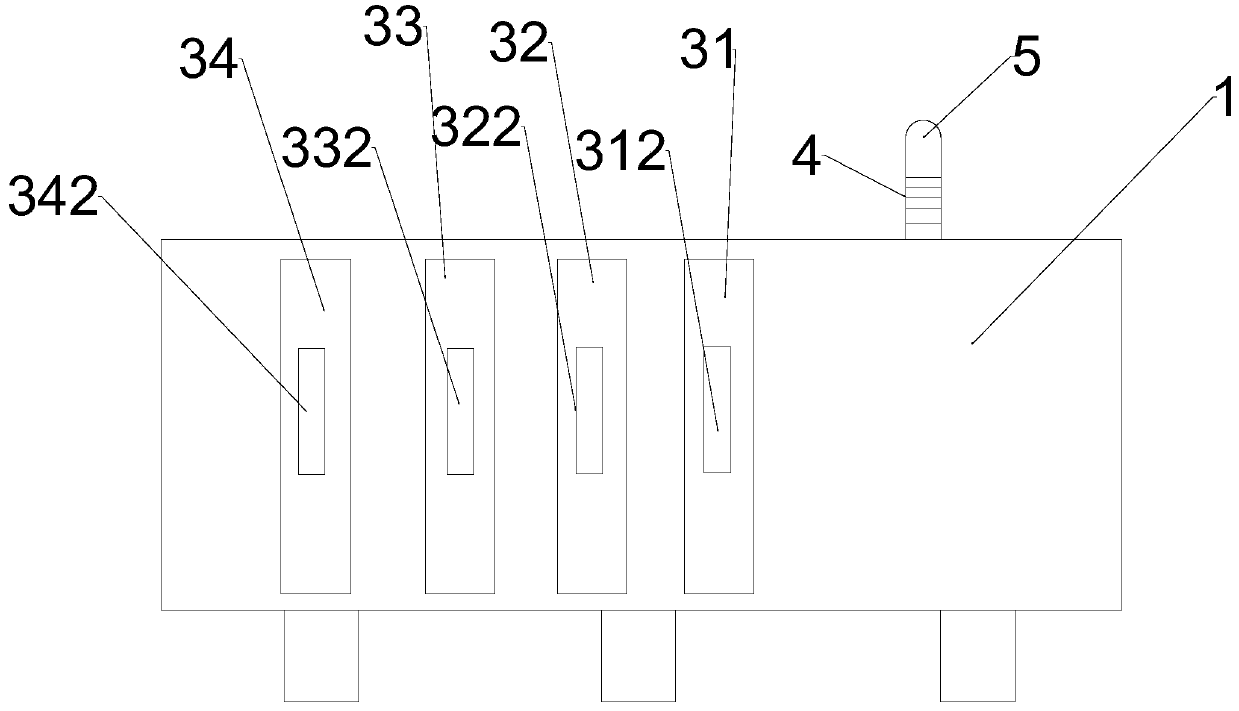

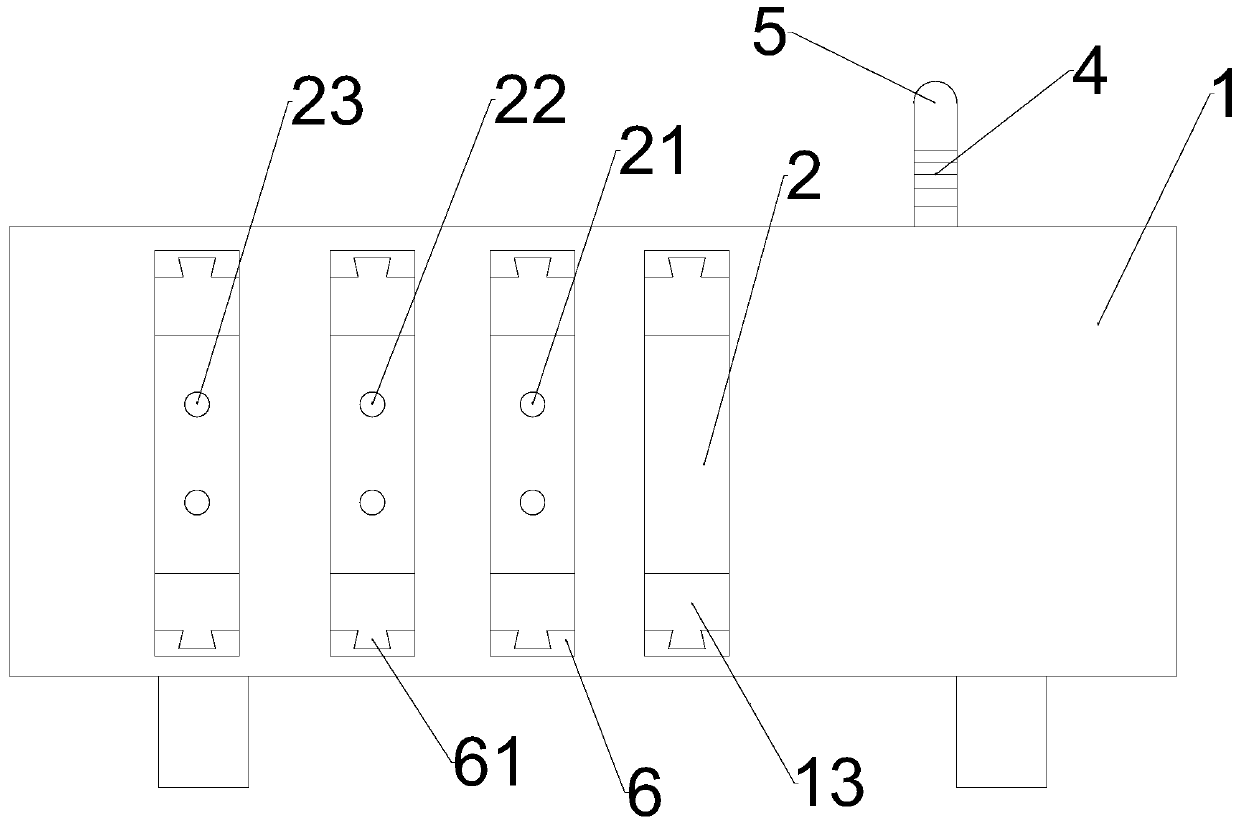

Detection system applied to tank fire control system

ActiveCN113686204AEasy to implementLarge operating spaceWeapon control systemsFire-control systemControl engineering

The invention discloses a detection system applied to a tank fire control system. The detection system comprises an operation platform, and a console driving part, a data acquisition part and a control part which are mounted on the operation platform; the console driving part is used for controlling a product console to perform pitching motion and horizontal rotation; the data acquisition part is used for acquiring and calculating an angular velocity value in the pitching motion and horizontal rotation process of an artillery and transmitting the angular velocity value to the control part; and the control part is used for driving the console driving part and carrying out quantitative index detection on the artillery according to the received angular velocity value. According to the detection system, technologies of data acquisition and analysis, servo control, mechanical design and the like are used as supports, a traditional method of functions and quantitative indexes of the tank fire control system is optimized, detection separation of the functions and the quantitative indexes of the tank fire control system is completed, automatic detection of the quantitative indexes is realized, the precision and efficiency are improved, and the labor cost is reduced.

Owner:CHINA NORTH VEHICLE RES INST

Air purification intelligent robot with mosquito repellent function

ActiveCN111442434AAchieve purificationRealize automatic turningMechanical apparatusLighting and heating apparatusMachineEnvironmental engineering

The invention provides an air purification intelligent robot with a mosquito repellent function. In the air purification intelligent robot with the mosquito repellent function, a main body of the robot has the function of detecting obstacles and can realize automatic turning, that is, the robot can be placed indoors to realize automatic path finding, and air purification of each corner in the roomis achieved. The air mixed with dust enters a machine shell from an air inlet, and the air mixed with dust penetrates through a pre-filter, a photocatalytic layer unit, a purple light unit, an electric mosquito liquid incense unit, a negative ion generator, an ozone generator in sequence and is treated by a plurality of module units; and an electric telescopic pole is further arranged, the electric telescopic pole is connected with a UV lamp, the electric telescopic pole can be controlled through a main control board to expand and contract so that the UV lamp can reach the designated positionfor sterilization; and meanwhile each module unit in the machine shell can be easily disassembled and taken out, is convenient for cleaning and convenient for maintenance and replacement.

Owner:东莞市恒达睿电子科技有限公司

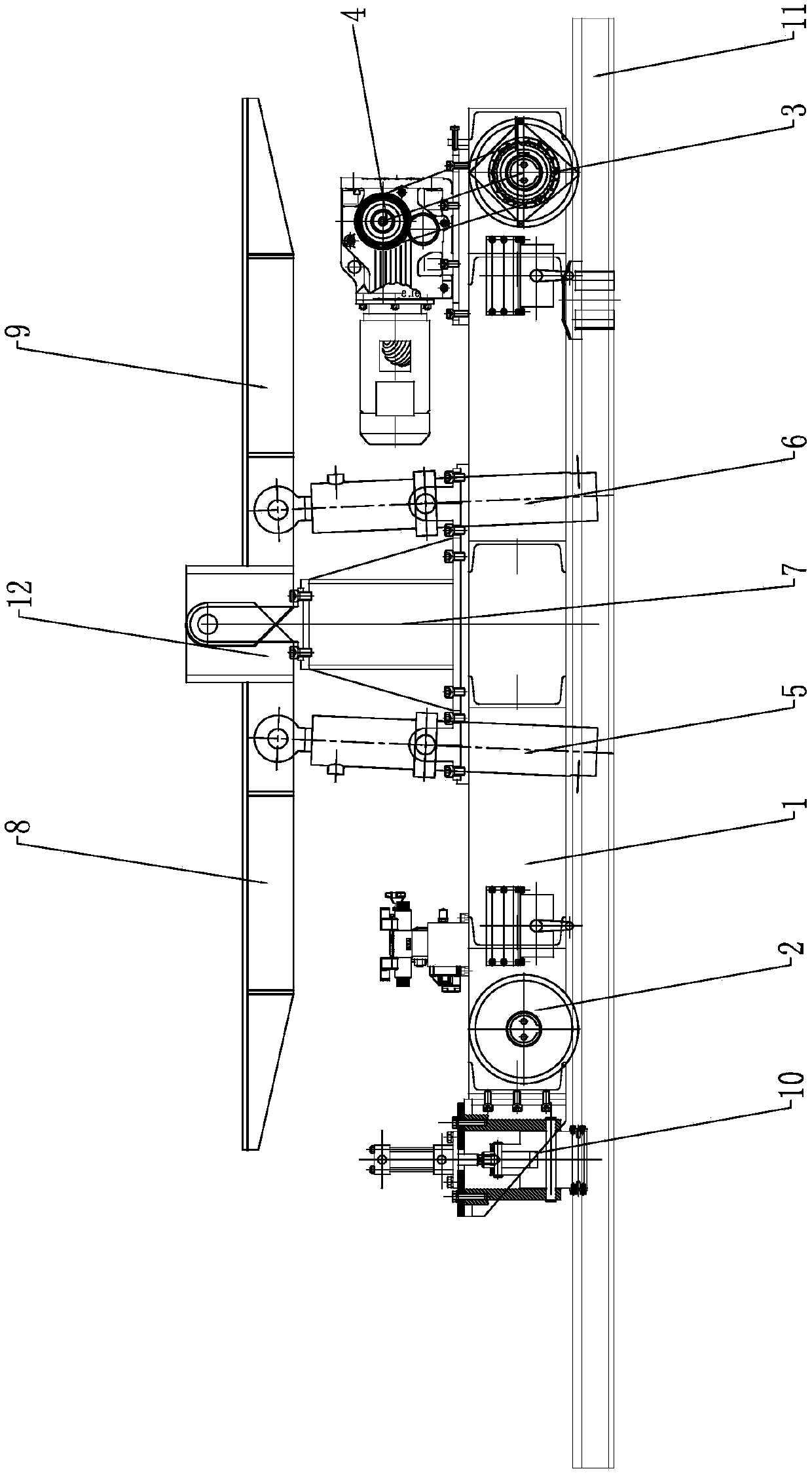

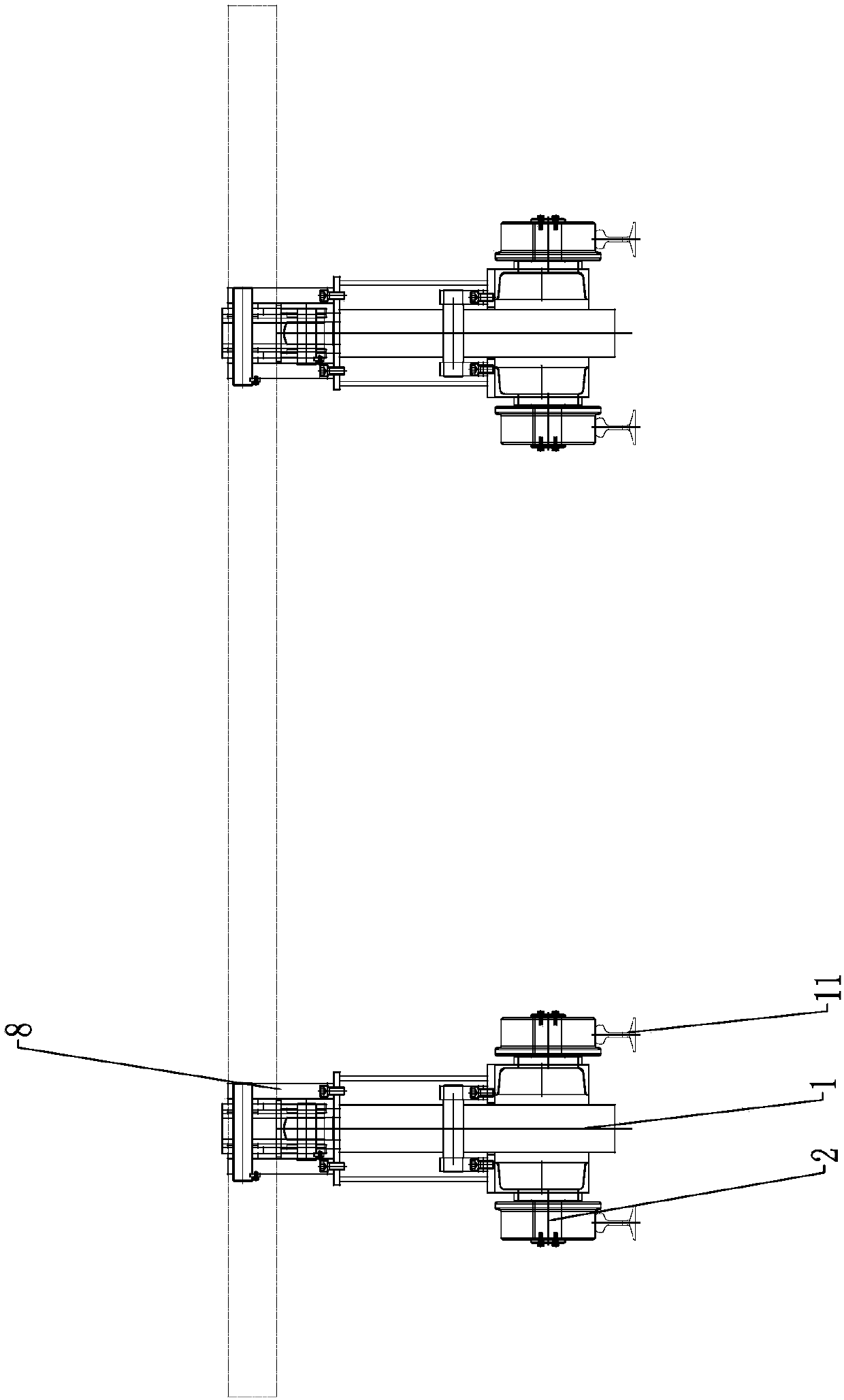

Automatic steel tube bundle overturning mechanism

PendingCN107671485ARealize automatic turningReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention relates to an automatic steel tube bundle overturning mechanism, in particular to conveying equipment used for achieving positive and negative overturning of steel tube bundles in the welding process in the steel tube bundle assembly line production process, and belongs to the technical field of steel tube bundle production equipment. The automatic steel tube bundle overturning mechanism comprises a walking rack, a driving mechanism, a first overturning oil cylinder, a second overturning oil cylinder, a first overturning arm and a second overturning arm, wherein an overturning arm support is fixed at the middle of the walking rack, a connecting frame is hinged to the overturning arm support, and the first overturning arm and the second overturning arm are connected to the left end and the right end of the connecting frame separately; and the first overturning oil cylinder and the second overturning oil cylinder are arranged at the left end and the right end of the overturning arm support, the front end of a telescopic rod of the first overturning oil cylinder is hinged to the first overturning arm, and the front end of a telescopic rod of the second overturning oil cylinder is hinged to the second overturning arm. According to the automatic steel tube bundle overturning mechanism, automatic overturning of the steel tube bundles can be achieved, and the automatic steel tube bundle overturning mechanism has the advantages of being high in conveying efficiency, intelligent, economical, safe, reliable, convenient and flexible to use, and capable of greatly reducing the labor intensity of workers and improving the working efficiency.

Owner:WUXI HUALIAN SCI & TECH GROUP

Intelligent closestool for smart home

PendingCN114108767AImprove comfortRealize automatic turningWater closetsBathroom coversControl valvesControl theory

The invention relates to the technical field of smart home, in particular to a smart toilet for smart home, and aims to solve the problem that a toilet in the prior art is poor in comfort, the smart toilet comprises a toilet body, the toilet body comprises a toilet body and a shell fixedly connected to the back of the toilet body, and a distance sensor is mounted on the front of the toilet body; a PLC is installed on one side of the barrel body, a flushing control valve is installed on the inner side of the shell, and a connecting pipe is fixedly connected to the bottom of the barrel body. The toilet bowl is reasonable and stable in structure, the height of the toilet bowl can be conveniently adjusted, the cushion can be automatically heated and deodorized, the using comfort of the toilet bowl is improved, and the toilet bowl is easy to popularize and use.

Owner:南京创斐信息技术有限公司

An air-purifying intelligent robot with the function of repelling mosquitoes

ActiveCN111442434BAchieve purificationRealize automatic turningMechanical apparatusLighting and heating apparatusAntiseptic sterilizationEngineering

This application provides an air purification intelligent robot with mosquito repelling function. In this application, the main body of the robot has the function of detecting obstacles and can realize automatic turning. Air purification: the air mixed with dust enters the casing from the air inlet, and the air mixed with dust passes through the pre-filter, photocatalytic layer unit, purple light unit, electric mosquito liquid incense unit, negative ion generator, and ozone generator in sequence , and processed by multiple module units; and it is also equipped with an electric telescopic rod, which is connected to a UV lamp, which can be controlled by the main control board to expand and contract the electric telescopic rod so that the UV lamp can reach the designated position for sterilization and disinfection. At the same time, each module unit in the casing can be easily disassembled and taken out, which is convenient for cleaning and maintenance and replacement.

Owner:东莞市恒达睿电子科技有限公司

A multi-functional electric turning bed

The invention provides a multifunctional electric stryker frame, and is applicable to the technical field of electronics. The multifunctional electric stryker frame comprises a rack, a controller, a left direct-current turbine motor, a right direct-current turbine motor and a hanging strap, wherein the controller is fixed on the top of the rack, and is electrically connected with the left direct-current turbine motor and the right direct-current turbine motor respectively; rotation of the left direct-current turbine motor and rotation of the right direct-current turbine motor are controlled by the controller; the controller is used for receiving a leftward turning-over command inputted by a user, inputs forward current to the left direct-current turbine motor so as to control forward rotation of the left direct-current turbine motor, and inputs reverse current to the right direct-current turbine motor by delaying two periods so as to control reverse rotation of the right direct-current turbine motor; and the absolute value of the forward current is equal to that of the reverse current. According to the technical scheme provided by a concrete implementing mode of the invention, the multifunctional electric stryker frame has an automatic turning-over function.

Owner:SHENZHEN LIFE BRAVE MECHANICAL TECH +1

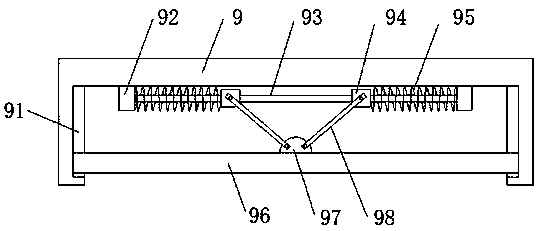

Sickbed for assisting automatic turn-over and transfer for patients

PendingCN110856681ARealize automatic turningReduce labor intensityNursing bedsPhysical medicine and rehabilitationSick person

The invention belongs to the technical field of rehabilitation medical devices and specifically relates to a sickbed for assisting automatic turn-over and transfer for patients. The sickbed includes abed frame and a roller mechanism. The roller mechanism includes a power drum and swinging plates. The swinging plates are rotatably connected with a crossbeam. A longitudinal pipe is arranged betweenthe two swinging plates, which are symmetrically arranged back and forth. An unpowered roller is arranged between the two swinging plates, which are symmetrically arranged back and forth. A fork plate is fixedly arranged in the middle part of the longitudinal pipe, and the end part of the fork plate is connected with a lead screw sleeve. The roller mechanism also comprises a lead screw and a transmission cloth. One end of the lead screw is connected with a rocker, and the other end of the lead screw is in threaded connection with the lead screw sleeve. The lead screw is connected on a longitudinal beam through a hoisting device. Two ends of the transmission cloth are respectively wound on power rollers on the left and right sides of the bed frame, and bypass the unpowered rollers. According to the invention, by adjusting the unpowered rollers arranged on the swing rod to different heights and driving with the power drum, automatic turn-over of patients sleeping on the transmission cloth is realized.

Owner:浙江佑仁智能机器人有限公司

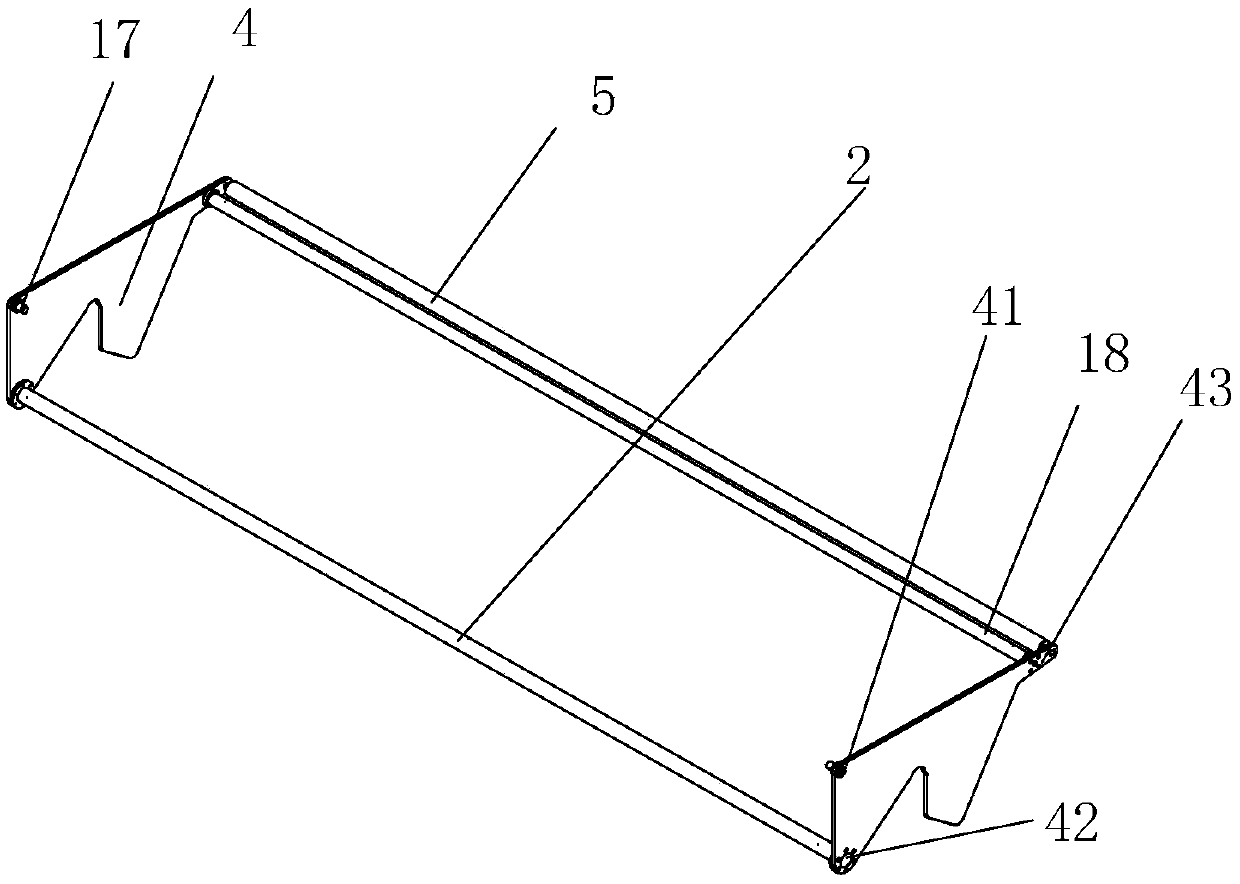

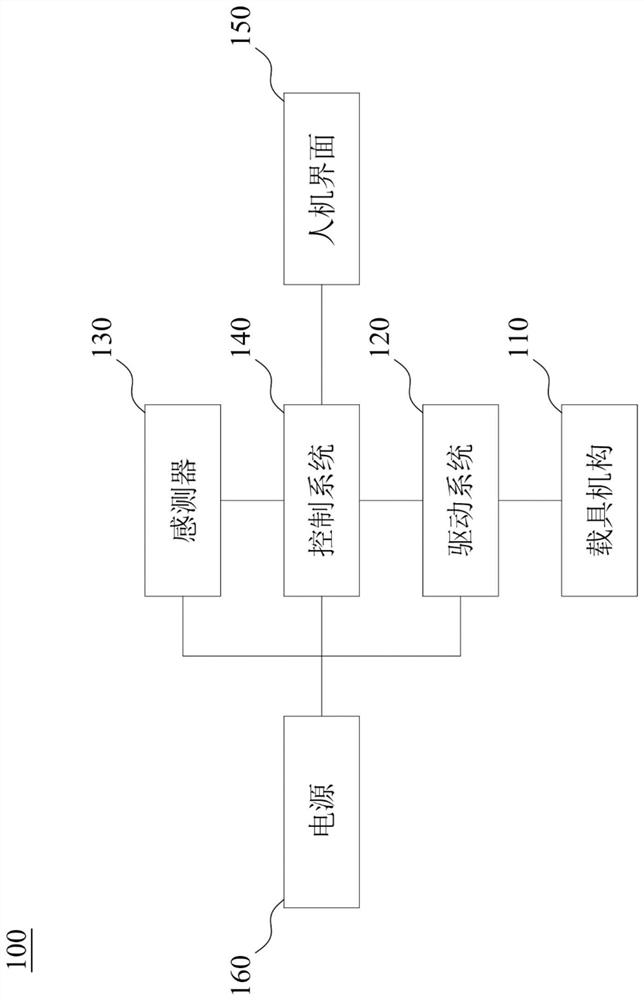

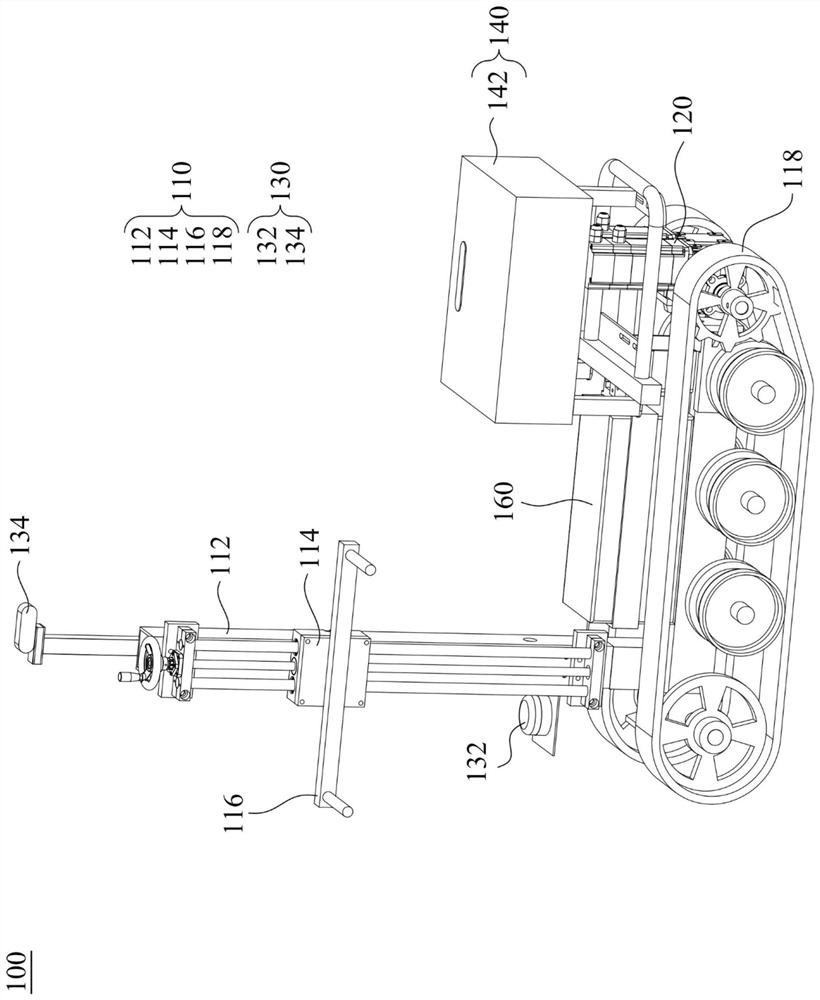

Carrier system

PendingCN113805575ARealize automatic turningPosition/course control in two dimensionsVehiclesInformation controlControl system

A carrier system capable of cooperating with a user comprises a carrier mechanism, a driving system, a sensor and a control system. The carrier mechanism is used for bearing a workpiece. The driving system drives the carrier mechanism to move on the moving path. The sensor detects movement information or an instruction of a user, and environment information within a range in the movement direction of the carrier mechanism. The control system is connected between the driving system and the sensor. The control system receives the movement information of the user and the environment information to establish a map of the detection range, and sets the current target within the boundary range of the map according to the movement information of the user or the instruction of the operator. The control system also plans a moving path according to the current position of the carrier mechanism and the current target, and moves along a tracking path. Therefore, the carrier system can realize cooperative work with the user.

Owner:颜炳郎

A quarter-turn conveying device and its working method

ActiveCN110921273BRealize automatic turningSolve the technical problems of inconvenient loading and unloadingConveyorsControl devices for conveyorsElectric machineryEngineering

The invention discloses a right-angle turning conveying device and its working method, comprising a belt conveyor A and a belt conveyor B, characterized in that: the belt conveyor A and the belt conveyor B are arranged at an angle of 90°, the belt conveyor A and the belt conveyor The intersection of the machine B is provided with a steering gear, the bottom of the steering gear is provided with a pulley unit, one side of the steering gear is provided with a push cylinder, and the belt conveyor A, belt conveyor B, and the steering gear are all provided with motors, The steering gear also includes a frame on which a rotating shaft A and a rotating shaft B are rotatably connected, one end of the rotating shaft A is fixedly connected to the output end of the motor, and the rotating shaft A and the rotating shaft B are evenly spaced A plurality of belt pulleys are sleeved, and a belt is connected between the belt pulley sleeved on the rotating shaft A and the belt pulley sleeved on the rotating shaft B. The purpose of the present invention is to solve the problems of inconvenient loading and unloading, inability of the conveying devices to turn, and inconvenient speed adjustment of the conveying devices caused by the combined use of multiple conveying devices.

Owner:山东炎黄工业设计有限公司

Glass fiber winder

ActiveCN114014092ARealize automatic turningRealize automatic top-upFilament handlingSevering textilesGlass fiberYarn

The invention discloses a glass fiber winder. The glass fiber winder comprises a winder body, a rotating disc, a plurality of machine heads and yarn guide wheels. The rotating disc is arranged on the winder body, the rotating disc can rotate, and a plurality of yarn guide rod sets are arranged on the rotating disc; the multiple machine heads are arranged on the rotating disc at intervals and rotate along with the rotating disc, the machine heads are matched with the yarn guide rod sets, and when one machine head in the multiple machine heads is in a preset state, the machine head adjacent to the machine head in the preset state is started in the clockwise or anticlockwise direction, after the number of meters of wound yarn balls on the machine heads in the preset state reaches the preset number of meters, the rotating disc rotates, and the yarn is guided to the next machine head from the previous machine head through the yarn guide rod set. The yarn guide wheel is used for guiding the yarn to the machine head in a preset state. According to the glass fiber winder, automatic cylinder turning and automatic head feeding of yarn in the winding process can be smoothly achieved, the operation procedures are reduced, the labor intensity is lowered, and the winding efficiency is improved.

Owner:JUSHI GRP CO

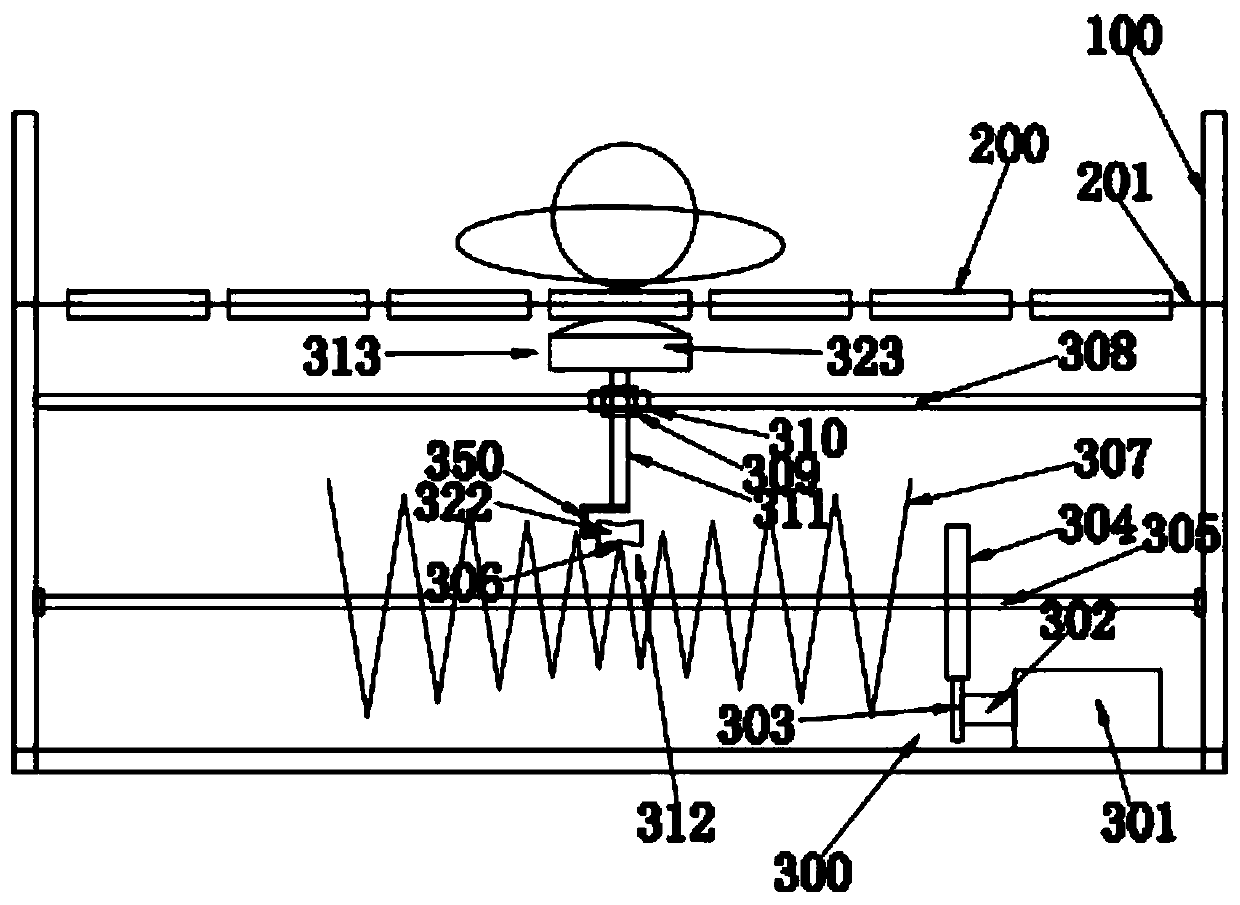

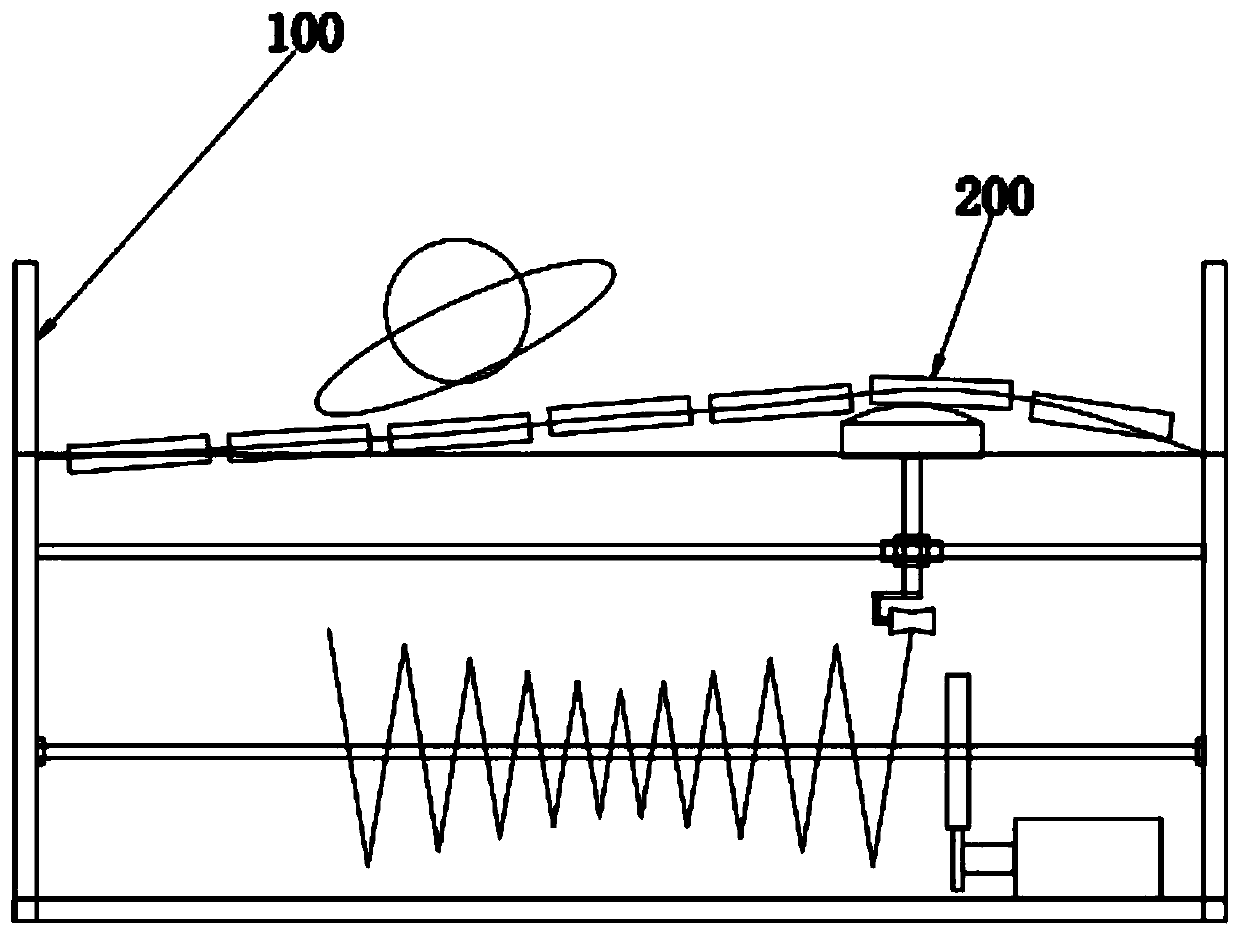

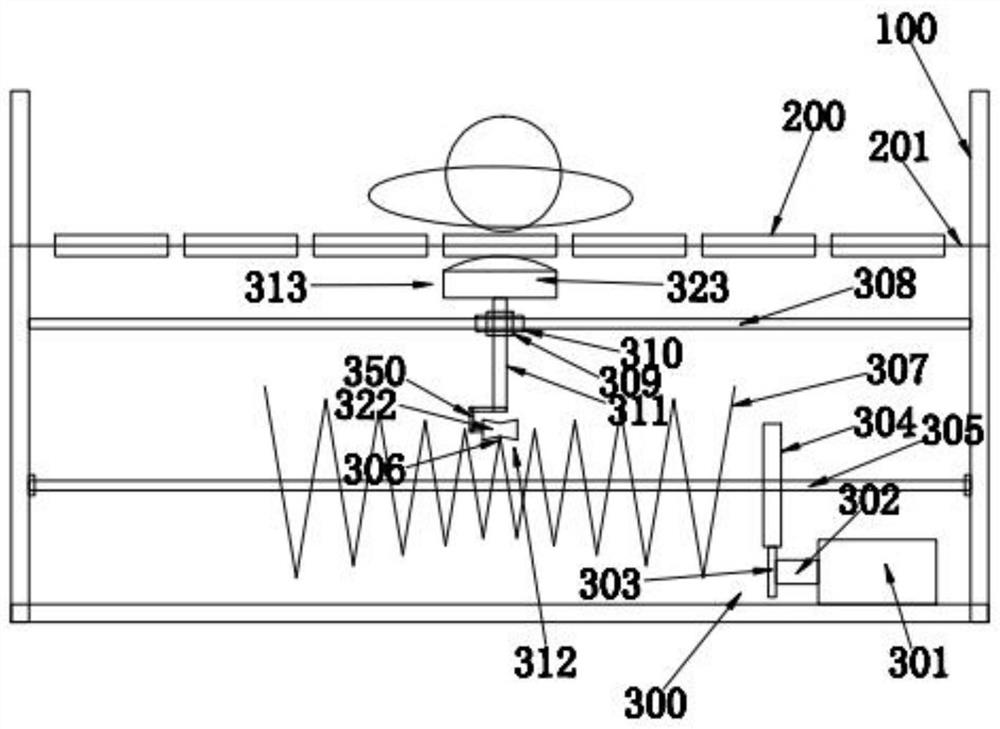

Medical sickbed and method

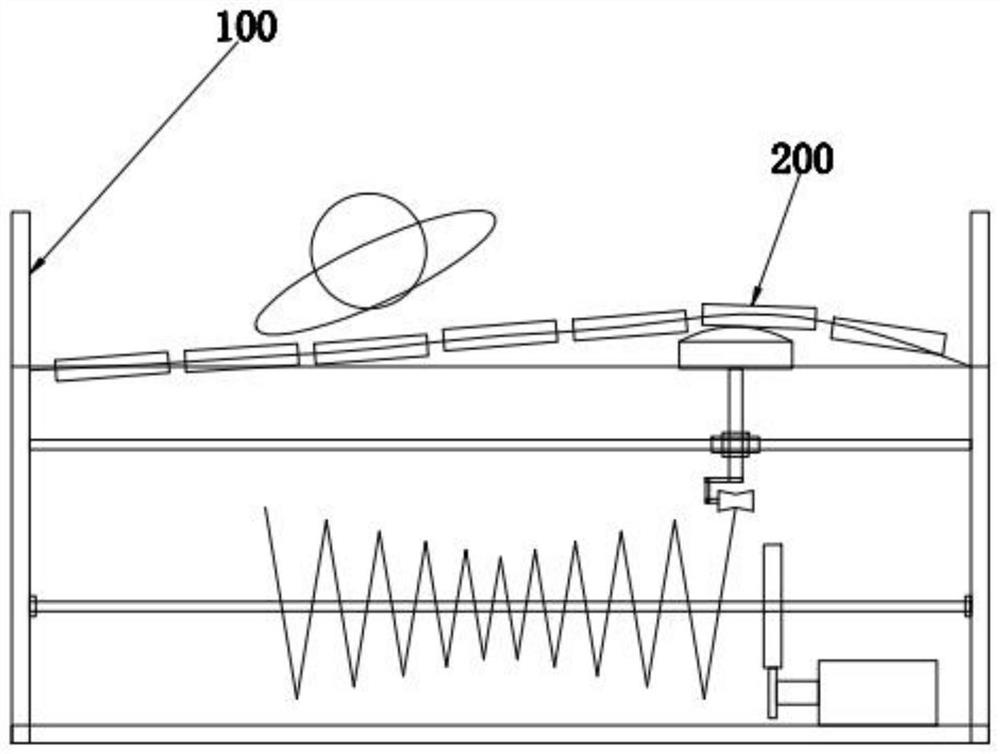

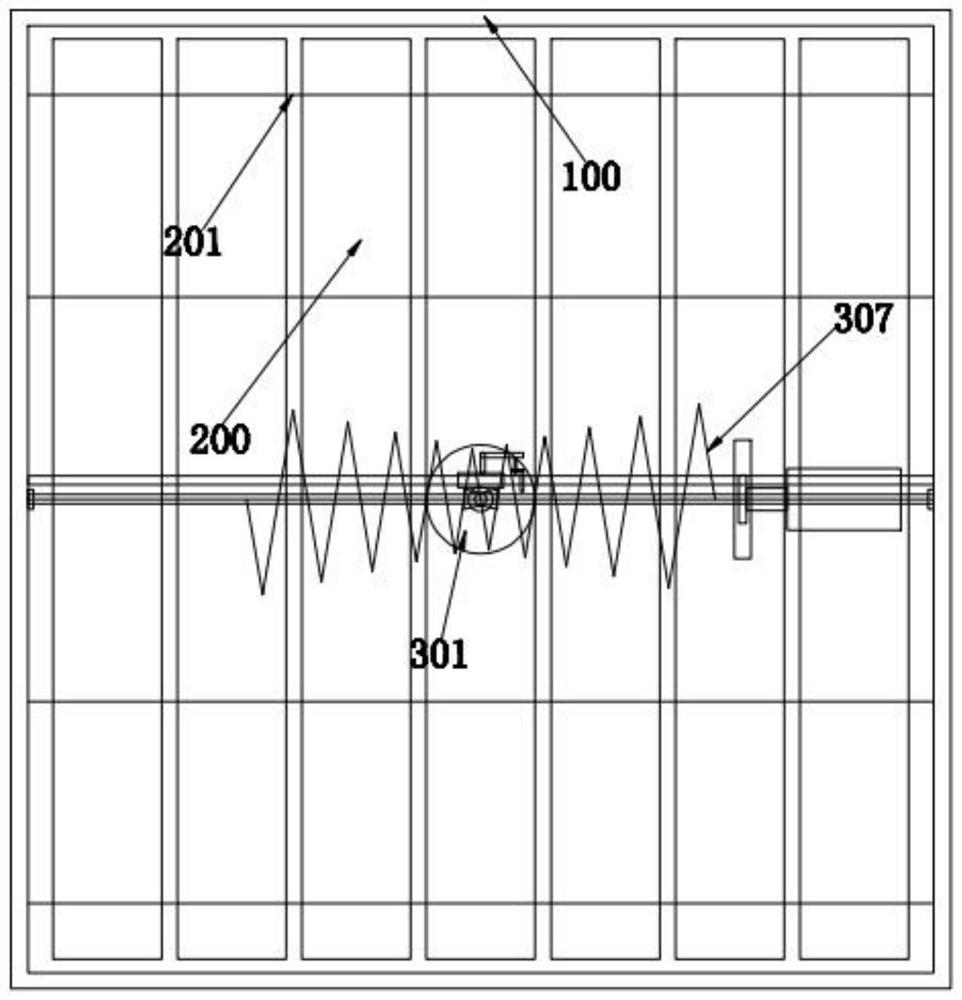

ActiveCN111407553ARealize automatic turningAvoid symptoms such as bedsoresNursing bedsAmbulance serviceMedicineWhole body

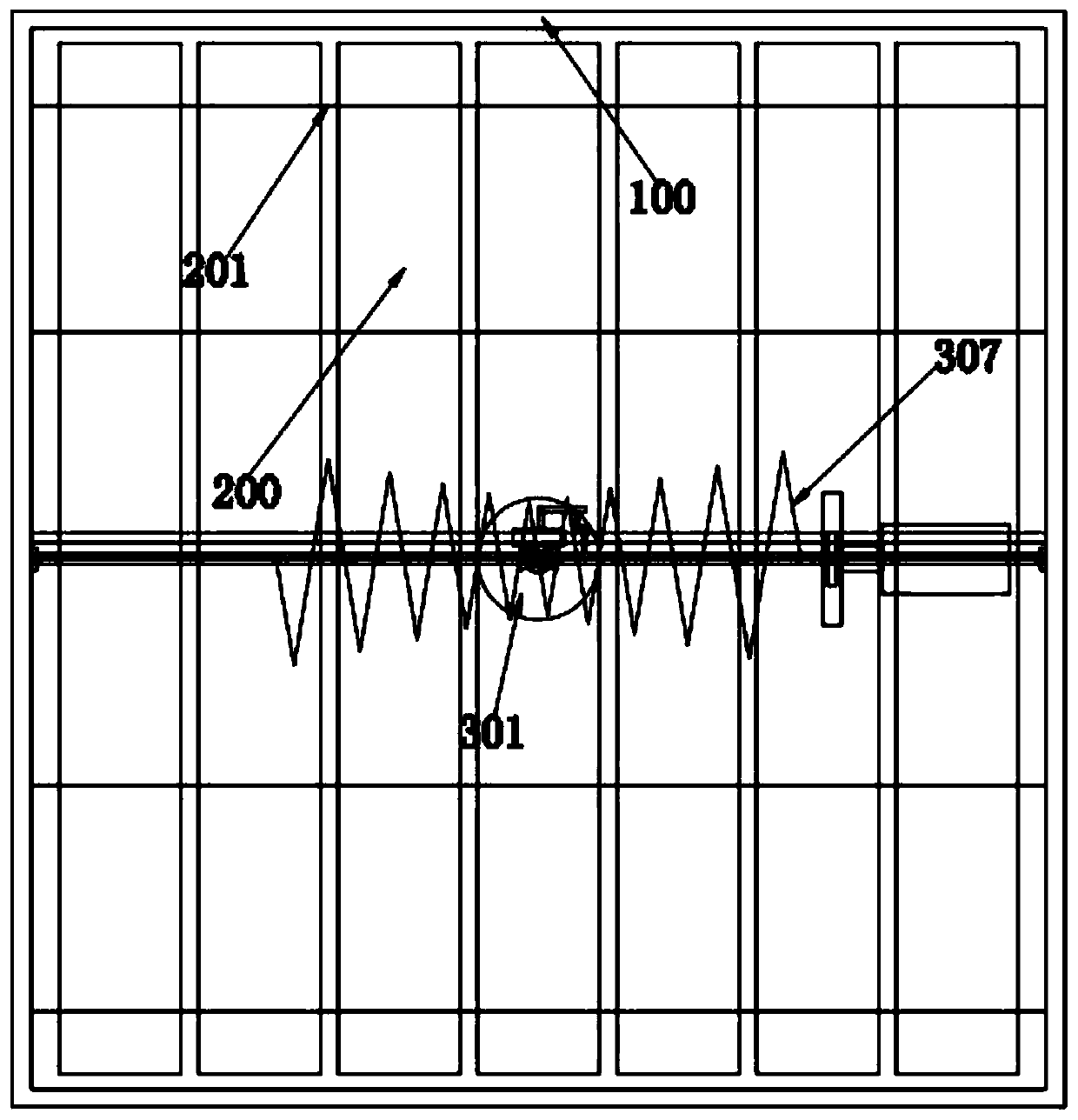

The invention discloses a medical sickbed. The medical sickbed comprises a bed box (100), at least three ribbed frames (200) and a turn-over part (300), a motor (301) drives a spiral guide rail (306)to rotate to enable a lifting rod (311) to rise and fall and move along a first guide rail (308) to change the up-down position of one or more of the at least three ribbed frames (200) and assist a user in turning over. The medical sickbed assists the user in turning over by adjusting one or more of the multiple ribbed frames (200) through the turn-over part (300), and can realize automatic turning over, guarantee sufficient blood supply for the whole body of the user and avoid symptoms such as pressure ulcer.

Owner:商青青

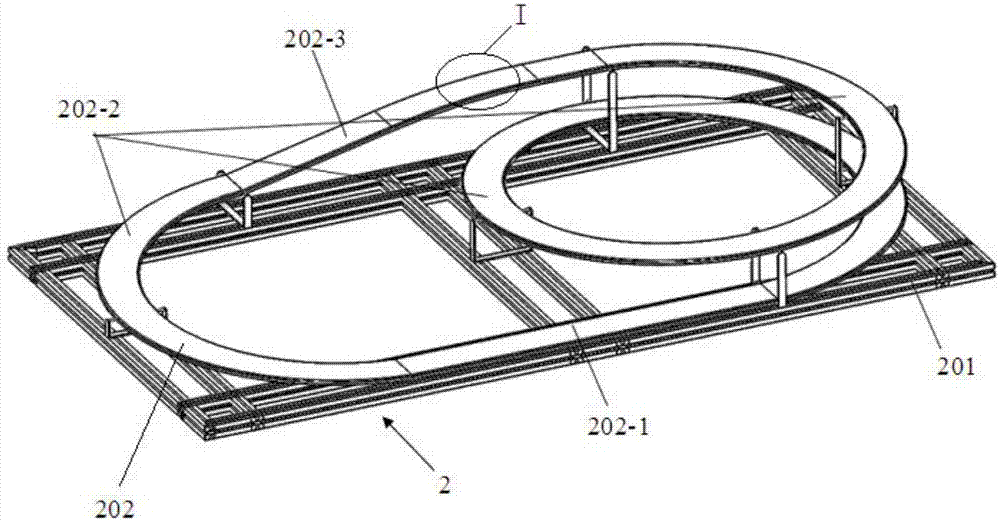

Pneumatic high-temperature superconducting magnetic levitation rail vehicle system

InactiveCN107351725AEasy to driveChange in ambient air pressureRailway vehicle testingElectric propulsionRemote controlHigh temperature superconducting

The invention discloses a pneumatic high-temperature superconducting magnetic levitation rail vehicle system. The pneumatic high-temperature superconducting magnetic levitation rail vehicle system comprises a remote controller, a permanent magnetic rail and a superconducting rail vehicle. The remote controller comprises a remote control box, a first pressing key, a second pressing key, a remote control battery and a signal emitting system. The permanent magnetic rail is made up of a circular rail fixed on a bracket. The superconducting rail vehicle comprises a vehicle type outer shell, and the front part of the vehicle type outer shell is internally provided with a vehicle body battery and a signal receiving system. The circular rail is evenly inlaid with permanent magnet bulks. The permanent magnet bulks are distributed in rows in the width direction of the circular rail and are distributed in columns in the length direction of the circular rail. An injecting hole is formed in the top of the vehicle type outer shell. A power system which adopts an air driving way is arranged at the tail of the vehicle type outer shell. A low-temperature vessel is arranged at the bottom of the vehicle type outer shell. The low-temperature vessel comprises a vessel room and an upward liquid nitrogen canned channel. High temperature superconducting bulks are evenly and symmetrically arranged in the vessel room. According to the pneumatic high-temperature superconducting magnetic levitation rail vehicle system, the manufacturing cost of the permanent magnetic rail is reduced, and the payload capacity of the superconducting rail vehicle is improved.

Owner:TIANJIN UNIV +1

Special driving and guiding device for air conditioner pipe robot

The invention discloses a special driving and guiding device for an air conditioner pipe robot. The special driving and guiding device comprises a movable vehicle body. A crawler belt moving mechanism and a guiding mechanism are arranged on the movable vehicle body. The crawler belt moving mechanism comprises crawler belts, crawler wheels, transverse wheel axles connecting the crawler wheels on the two sides and a crawler belt driving motor. The crawler belt driving motor drives the crawler belts to move forwards or backwards by driving at least one transverse wheel axle. The guiding mechanism comprises guide wheels arranged on the front portions of the left and right sides of the crawler belts. The guide wheels are connected to guide wheel carriers through guide wheel axles. The guide wheel carriers are fixedly connected to the movable vehicle body through slanting supporting plates. The guide wheel axles on the left and right sides are in driving connection with a guide wheel driving motor arranged on the movable vehicle body. The guide wheel driving motor drives the guide wheels to rotate. The special driving and guiding device can automatically make a turn through the guide wheels.

Owner:天津中化洁安科技股份有限公司

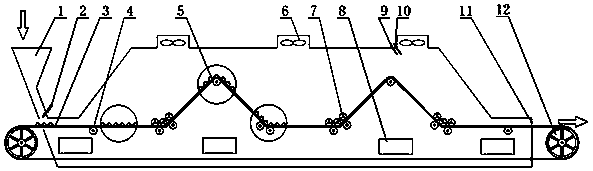

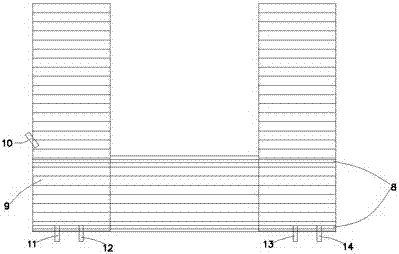

Arch Bridge Ladder Conveyor Tunnel Dryer

InactiveCN107957179BDry evenlyKeep dryDrying gas arrangementsDrying machines with progressive movementsBridge typeWaste product

The invention discloses an arch bridge ladder conveying type tunnel drying machine. The arch bridge ladder conveying type tunnel drying machine comprises a drying box. One end of the drying box is a feeding port, the other end of the drying box is a discharging port, a conveying belt is arranged between the feeding port and the discharging port, power rolling wheels are arranged at the two ends ofthe conveying belt correspondingly, and the power rolling wheels are connected with a variable frequency motor through a reduction box; and the conveying belt is a transportation screen mesh made ofstainless steel, the hole diameters of the transportation screen mesh are 0.1-1.0 cm, supporting rolling wheels are arranged on the lower portions of the transportation screen mesh, and the transportation screen mesh is an arc bridge type ladder conveying belt. According to the arch bridge ladder conveying type tunnel drying machine, automatic turnover can be conducted on materials containing water, piece-shaped materials, block-shaped materials, strip-shaped materials, spoon-shaped materials and powder prone to being blocked in the drying process or irregular materials through the arch bridgeladder conveying type tunnel drying machine, material drying is more even through surrounding hot wind on the lower portion of the drying box, and waste products are obviously reduced.

Owner:HUAIAN HIGH TECH INST OF LANZHOU UNIV +5

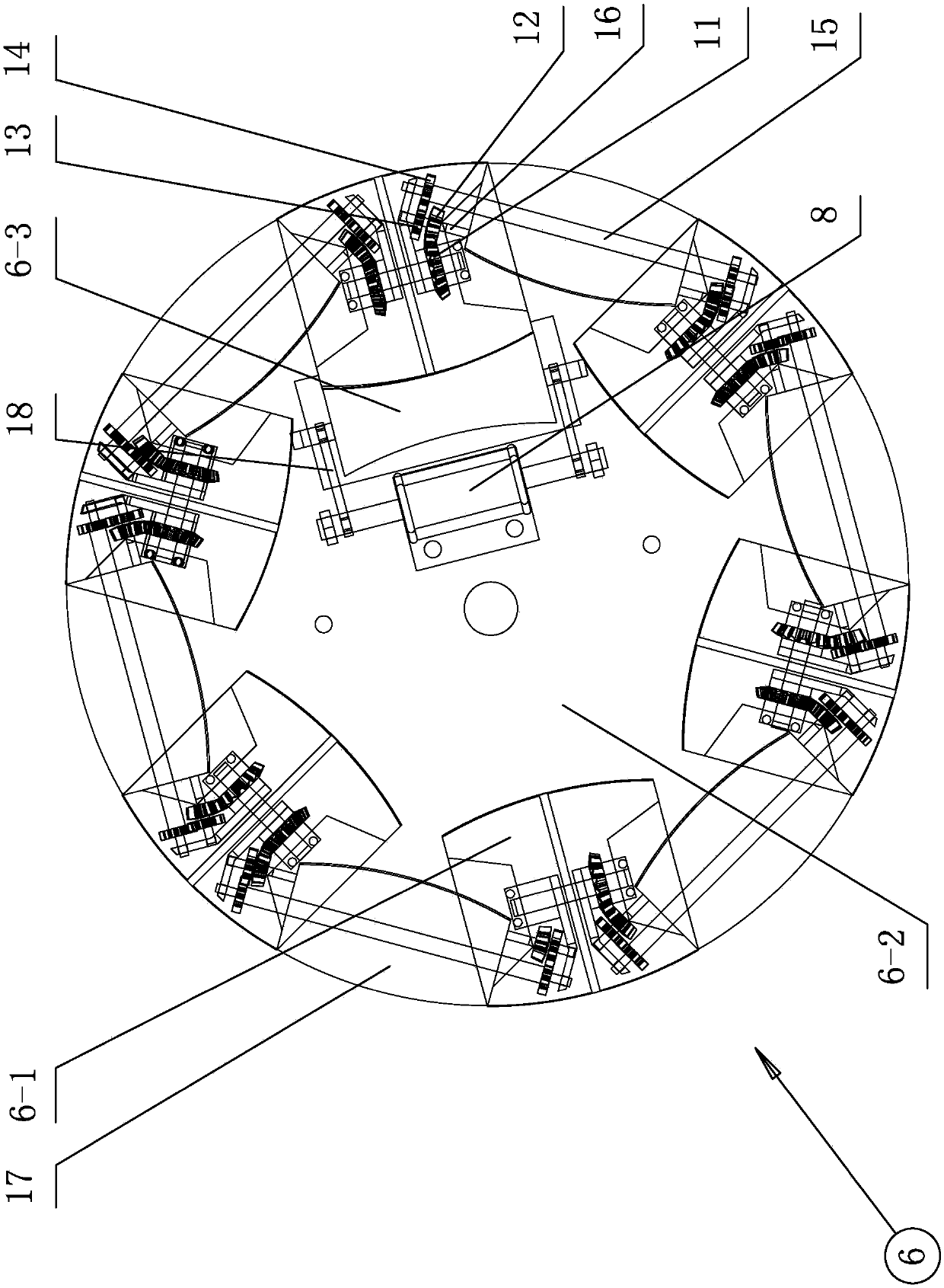

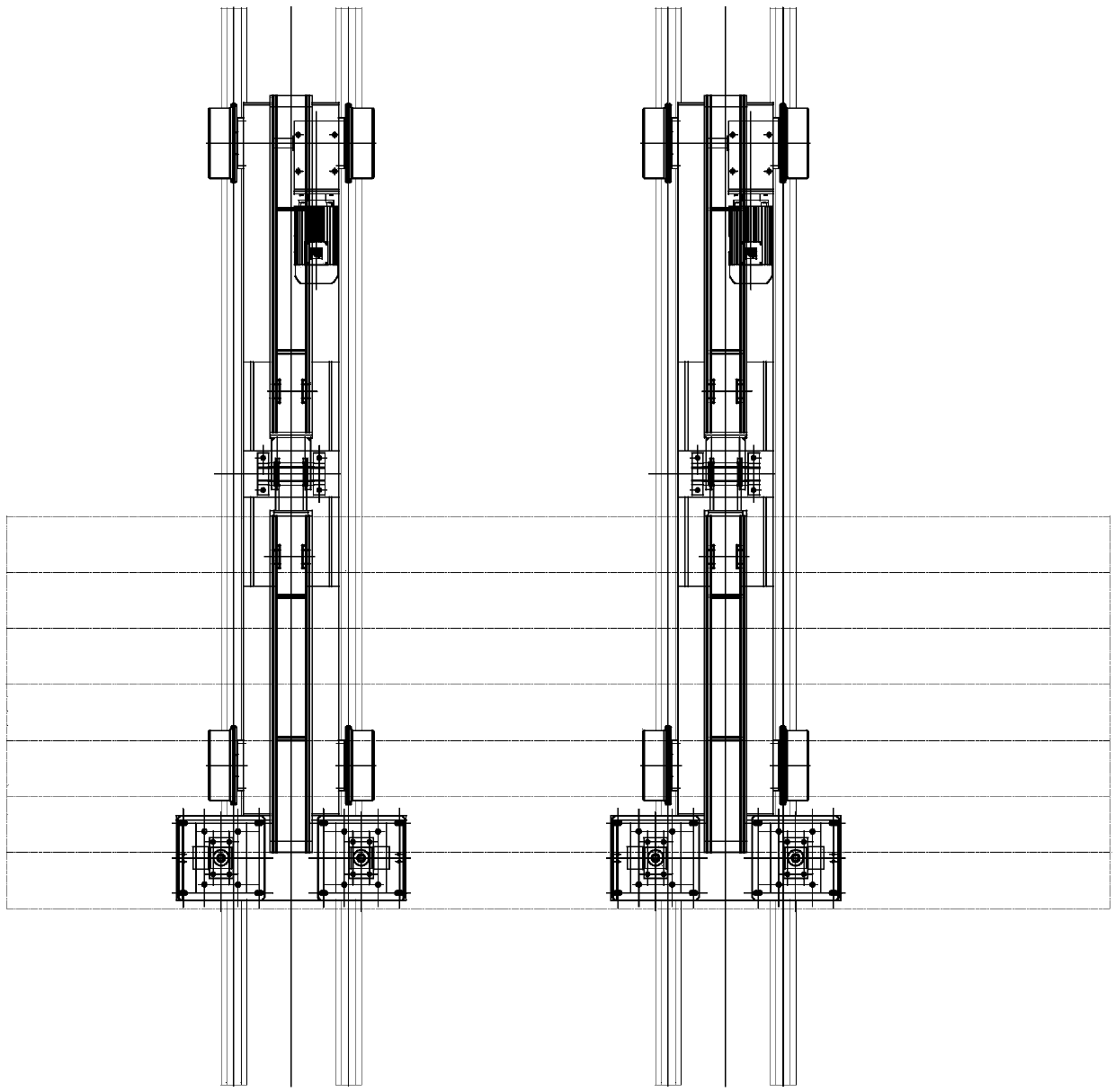

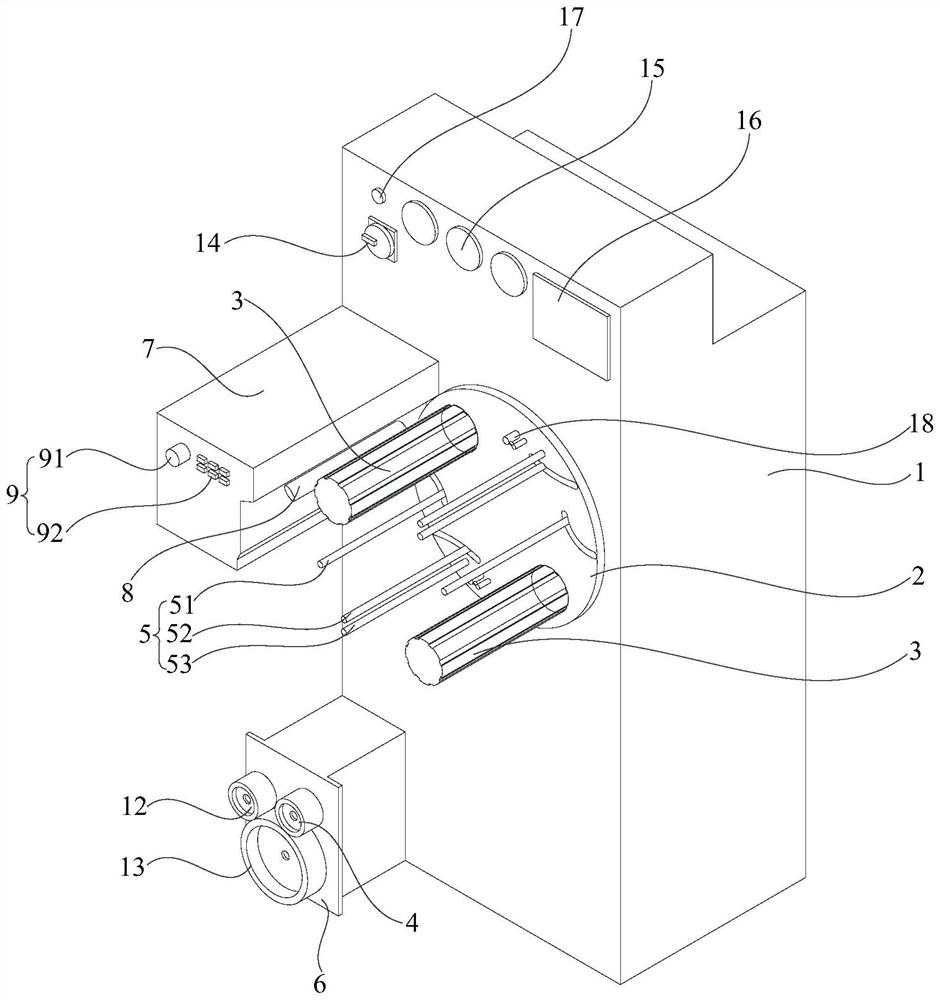

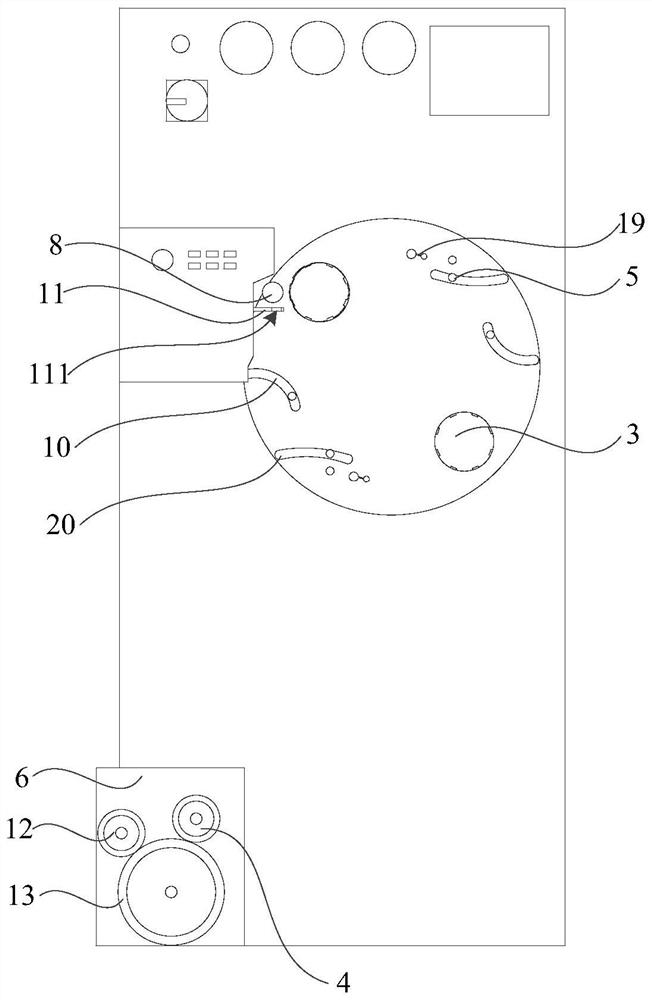

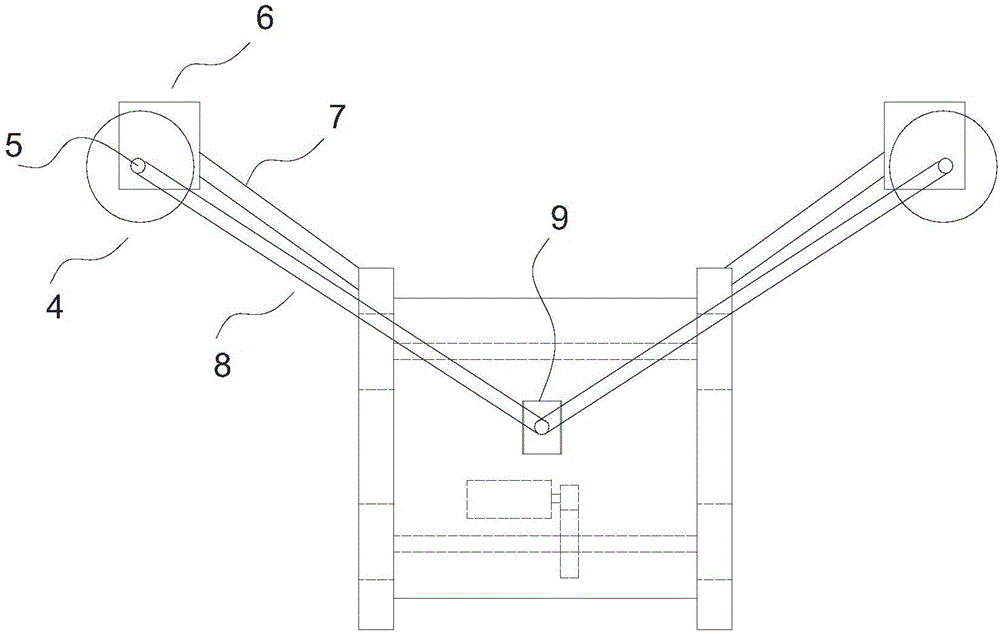

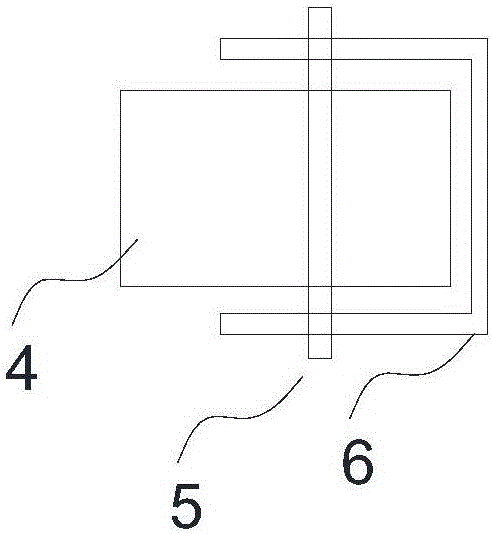

Automatic turning machine for roller kiln

The invention discloses an automatic turning machine for a roller kiln. The automatic turning machine structurally comprises a motor (1), a bearing (2), an eccentric wheel (3), a shaft sleeve (4), a fixing frame (5), a chain wheel (6), a movable frame (7), a double supporting plate chain (8), a roller stick (9), an acceleration induction monitor (10), deceleration induction monitors (11) and (13) and positioning induction monitors (12) and (14). According to the automatic turning machine, the roller kiln can automatically turn by 90 degrees, the using space is reduced, and the automatic turning machine can replace manual work to automatically push products into the kiln through the time difference.

Owner:徐新毅

A kind of medical bed and method

ActiveCN111407553BRealize automatic turningAvoid symptoms such as bedsoresNursing bedsAmbulance serviceWhole bodyMechanical engineering

A medical bed of the present invention includes a bed box (100), at least three row frames (200), and a turning part (300). Moving along the first guide rail (308), the up and down positions of one or more of the at least three row frames (200) are changed to assist the user to turn over. The present invention assists the user to turn over by adjusting the upper and lower positions of one or more of the plurality of row frames (200) through the turning part (300), which can realize automatic turning, ensure sufficient blood supply to the user's whole body, and avoid symptoms such as bed sores.

Owner:商青青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com