Full-automatic rolling device of egg roll making machine

A fully automatic, egg roll machine technology, applied in food preparation, food forming, food science and other directions, can solve the problems of labor-intensive, poor working environment, low processing efficiency, etc. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

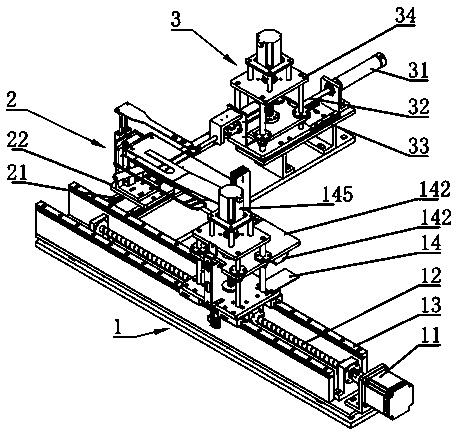

[0033] Attached below Figure 1-4 The present invention is described further:

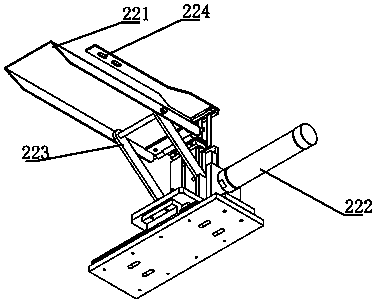

[0034] A fully automatic rolling device of an egg roll machine according to the present invention comprises a roll taking and turning assembly 1, a turning platform assembly 2, and a secondary turning assembly 3;

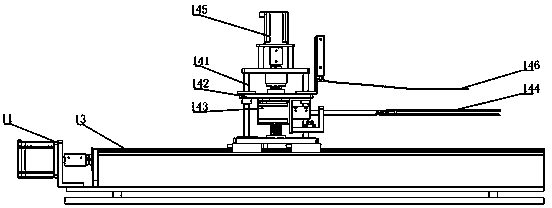

[0035] The take-up turning assembly includes a stepping servo motor 11, a ball screw drive 12 connected to the output shaft of the stepping servo motor, a linear guide rail 13 arranged horizontally, and a take-up turning bracket 14 movably arranged on the linear guide rail ;

[0036] A linear bearing 141 is arranged vertically on the take-up turning bracket, a rolling fixed plate 142 is movable on the linear bearing, a rolling motor 143 is fixedly arranged on the rolling fixed plate, and the output of the rolling motor The shaft is connected with a turning fork 144 through a shaft coupling, and a pressing piece 146 is arranged above the turning fork, and the take-up turning bracket als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com