Seat hook type hoist bucket

A technology of seat hook and bucket, applied in the direction of load hanging components, shaft equipment, mining equipment, etc., can solve the problems of restricting the construction speed of the shaft project, unable to be introduced into domestic use, etc., and achieve the effect of convenient construction and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

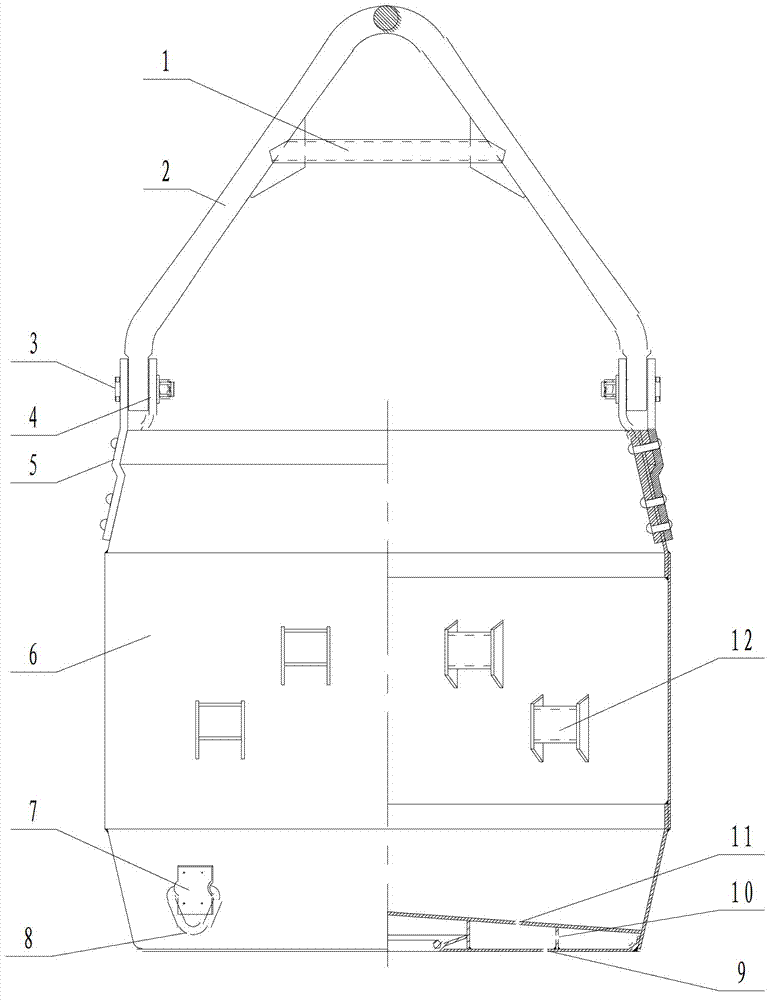

[0029] A hook-type bucket includes a bucket beam 2, an inner earring 4, an outer earring 5, a bucket body 6 and a double-layer bucket bottom. The bucket beam 2 is set on the top of the bucket body 6 and is riveted to the The inner earring 4 on the inner side of the top of the barrel body 6 and the pin 3 of the outer earring 5 riveted on the outer side of the top of the barrel body 6 are hinged between the inner earring 4 and the outer earring 5. The barrel body 6 The bottom is fixed with a double-layer barrel bottom.

[0030] A circular seat hook through hole is provided in the center of the lower barrel bottom 9 of the double-layer barrel bottom, and a supporting rib 10 is welded between the upper barrel bottom 11 and the lower barrel bottom 9 of the double-layer barrel bottom.

[0031] On the inner side of the pin 3 passing through the outer ear ring 5, the barrel beam 2, and the inner ear ring 4 in sequence, the pin 3 also passes through a washer and a nut, and a guard is also p...

Embodiment 2

[0043] In this embodiment, the structure and usage of the bucket are basically the same as those in Embodiment 1, except for the volume of the bucket body 6, the height of the bucket body 6, the overall height and quality of the bucket.

[0044] The following are the basic parameters of a hook-type bucket with a volume of 7 cubic meters:

[0045] Wherein, the volume of the barrel body 6 is 7 cubic meters, the height of the barrel body 6 is 2440 mm, the full height of the bucket is 4025 mm, and the mass is 2375 kg.

[0046] It can be seen that according to the design diameter of the domestic shaft project (maximum 10m), considering the plane layout of the construction equipment in the shaft and the lifting capacity of the supporting sinking facilities, if you want to achieve a larger bucket volume, increase the barrel 6 It is the optimal solution to increase the volume of the bucket. Furthermore, the volume of the barrel is designed to be 7 cubic meters, which has the strongest versa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com