Three-way stacking forklift with portal capable of moving laterally and moving along with rotation

A gantry and follow-up technology, applied in the direction of lifting devices, etc., can solve the problems of bridge components such as heavy weight, complex structure, and affecting the driver's vision, and achieve the effect of high safety and good driving vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

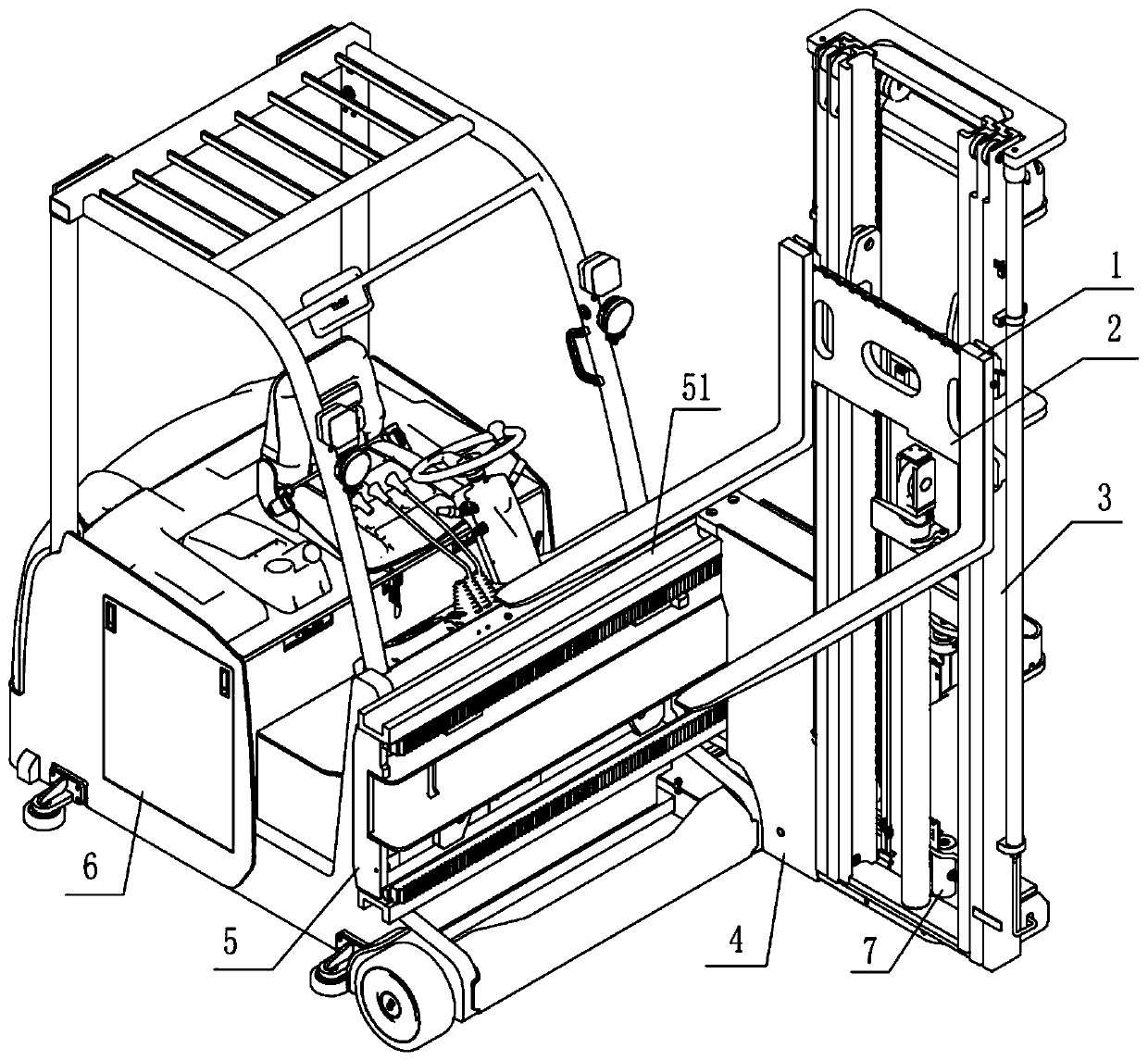

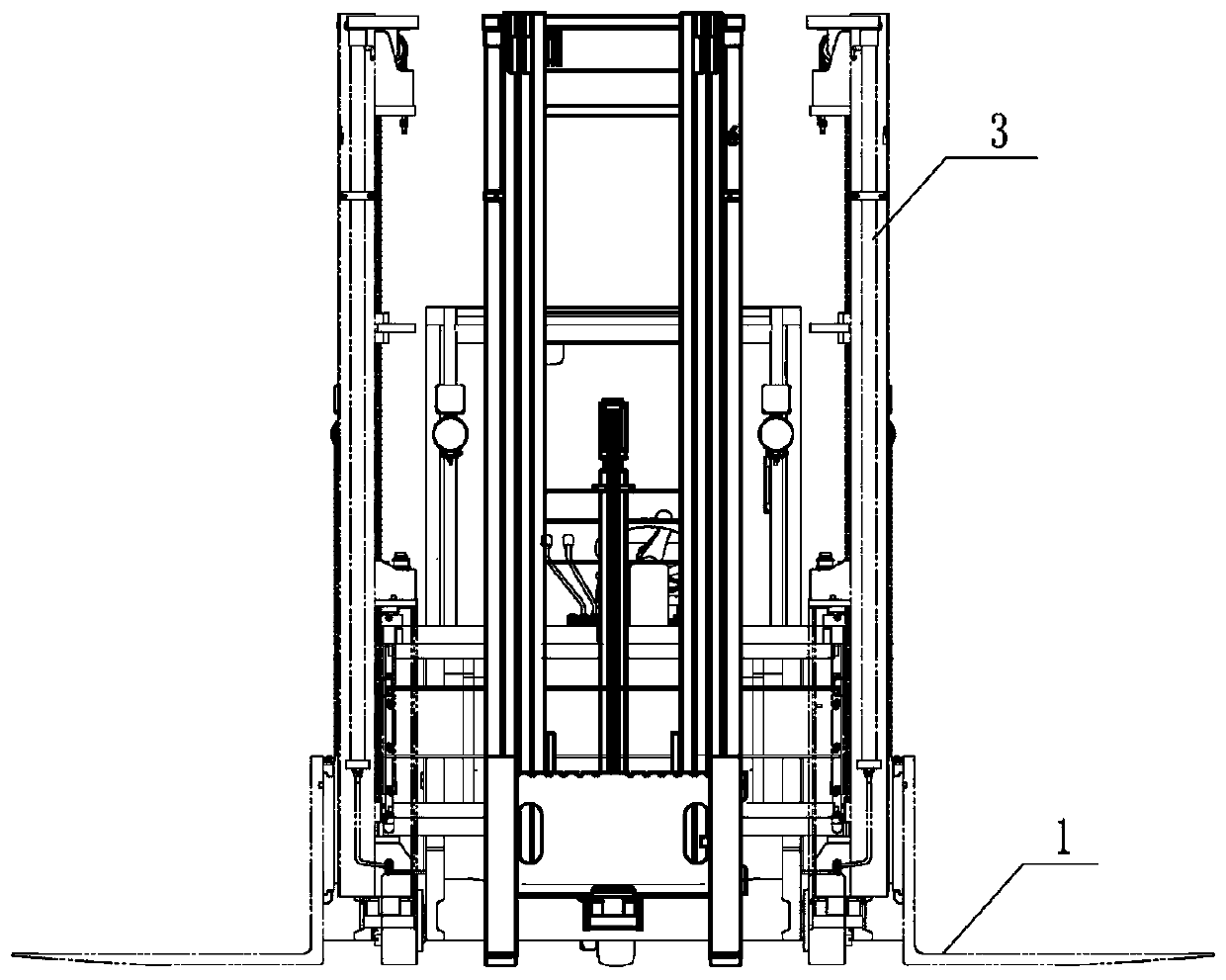

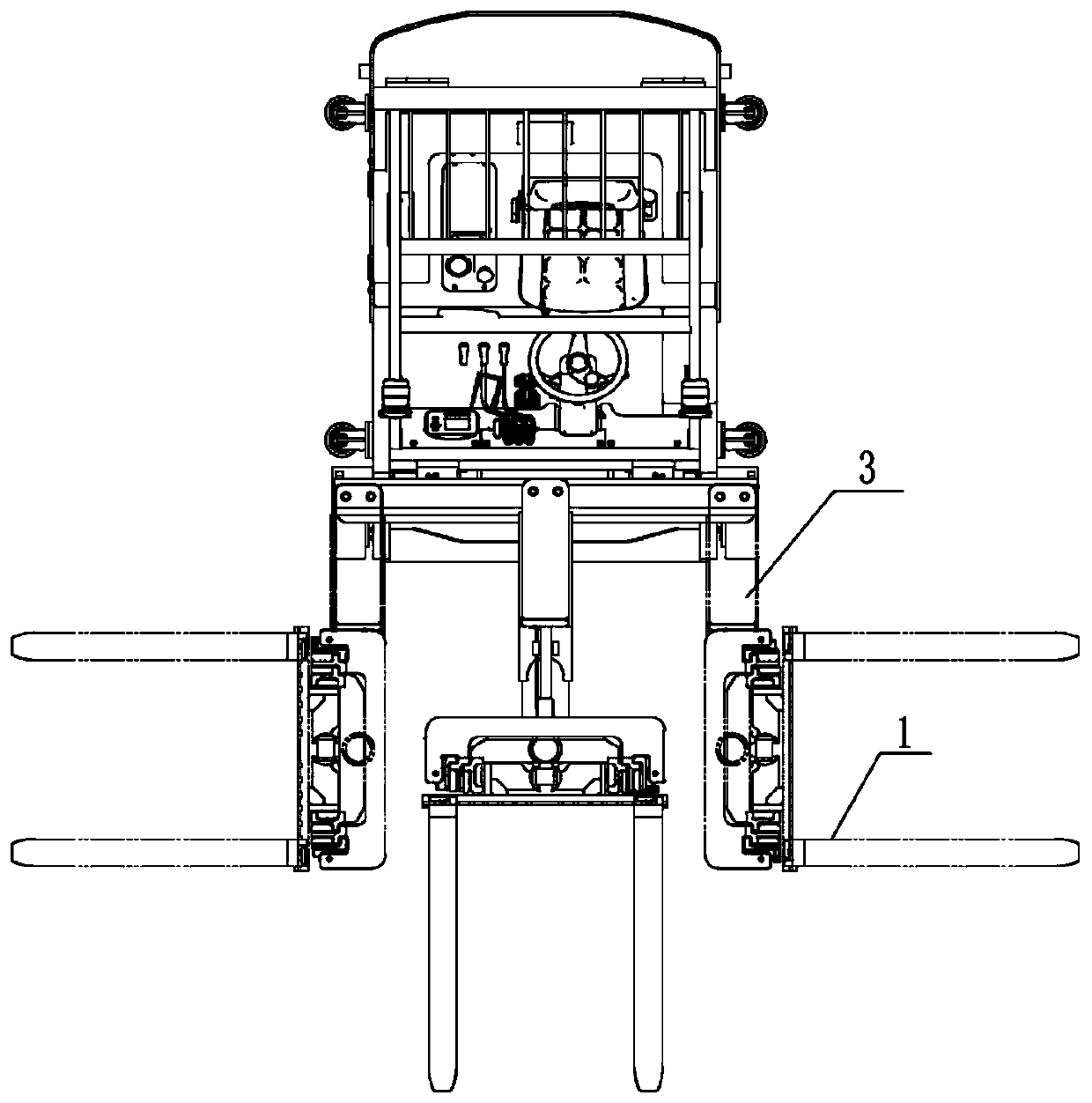

[0018] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0019] A three-way stacking forklift with mast moving sideways and following rotation, comprising a fork 1, a fork frame 2, a mast system 3, a bridge assembly 4, a side moving carriage 5, a body system 6 and a rotating shaft 7, wherein :

[0020] The fork 1 is installed on the fork frame 2, so the fork 1 can move synchronously with the fork frame 2, and the rear side of the fork frame 2 fits in the guide groove on the mast system 3, so it is in the mast system 3 Form a moving pair, and the transmission parts inside the mast system 3 can directly drive the fork frame 2 to move up and down to achieve the effect of fork delivery of goods. The side shift carriage 5 is fixedly installed on the front end of the body system 6, and the side shift carriage 5 A linear track 51 is provided on the top, and the end of the bridge assembly 4 fits in the linear track 51 and forms a moving pair in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com