Colored asphalt and production method thereof

A technology for colored asphalt and a production method, which is applied in the directions of chemical instruments and methods, mixers, mixers with rotary stirring devices, etc., can solve the problems that restrict the popularization and application of colored asphalt pavement, difficulty in large-scale production, and high prices. , to achieve the effect of low cost of production raw materials, improved vision, and reduced production costs and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A colored asphalt, comprising the following components by weight: 60-80 parts of petroleum resin, 30-50 parts of base oil, 10-20 parts of coupling agent, 10-20 parts of epoxy resin, 10-20 parts of rubber powder 10-20 parts of SBS modifier, 5-8 parts of inorganic filler, 4-6 parts of anti-aging agent.

[0044] Among them, the base oil is mineral oil, preferably diesel oil; the rubber powder is styrene-butadiene rubber powder; the SBS modifier is one or a mixture of linear SBS and star SBS; the anti-aging agent is 2-hydroxy -4-methoxybenzophenone and 2,6-di-tert-butyl-4-methylphenol are mixed at a mass ratio of 2:1; the inorganic pigments are iron red pigments, chrome green pigments, iron green pigments, A mixture of one or more of titanium dioxide pigments and chrome yellow pigments.

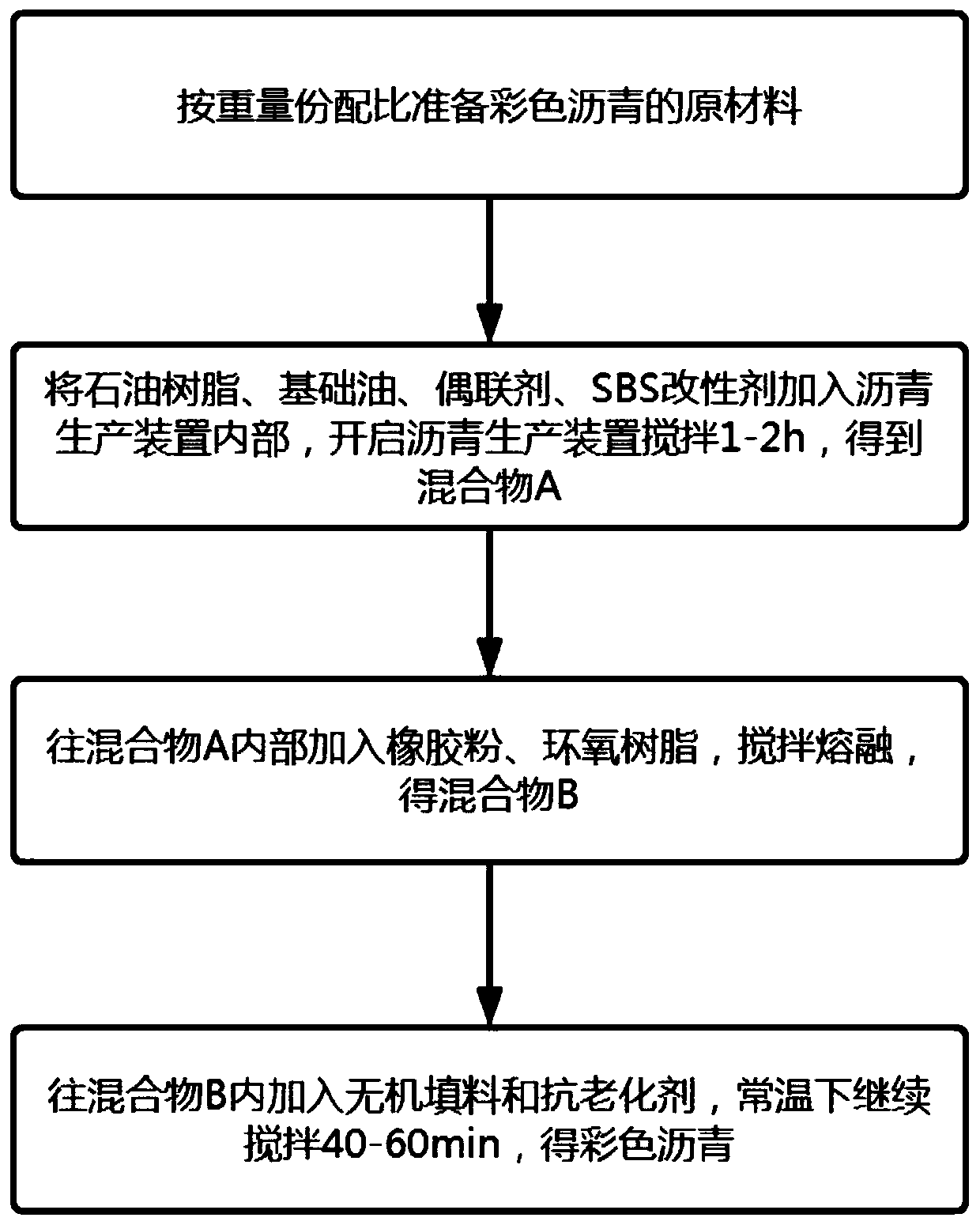

[0045] see figure 1 , a kind of production method of colored asphalt, specifically comprises the following steps:

[0046] S1, prepare the raw material of colored asphalt according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com