Steel structure fabricated external wall ALC wallboard flexible connection method

A prefabricated, steel structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large amount of welding of external wall panels, slow construction progress, high-altitude operations, etc., achieve superior seismic performance, improve damping ratio, The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

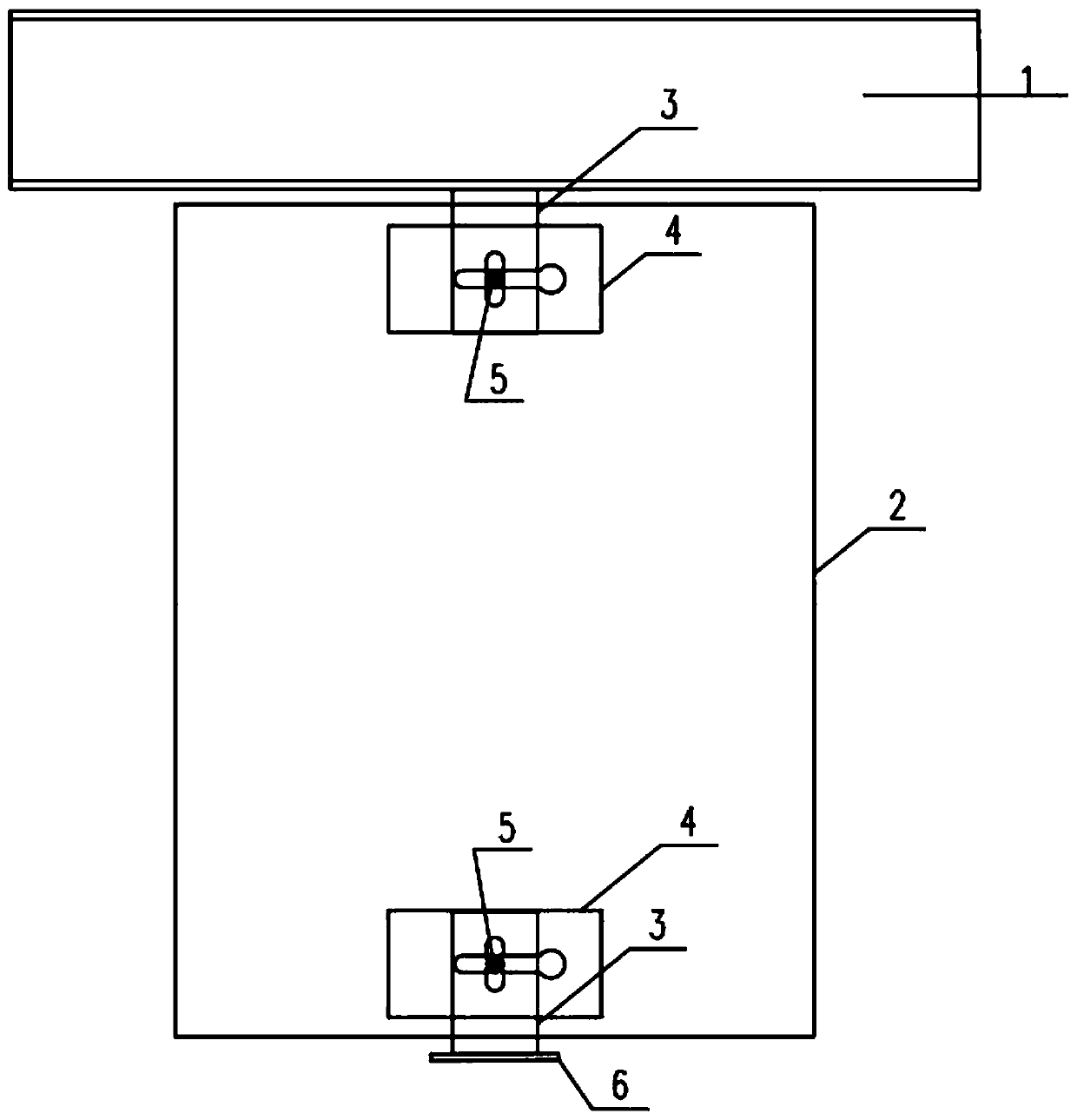

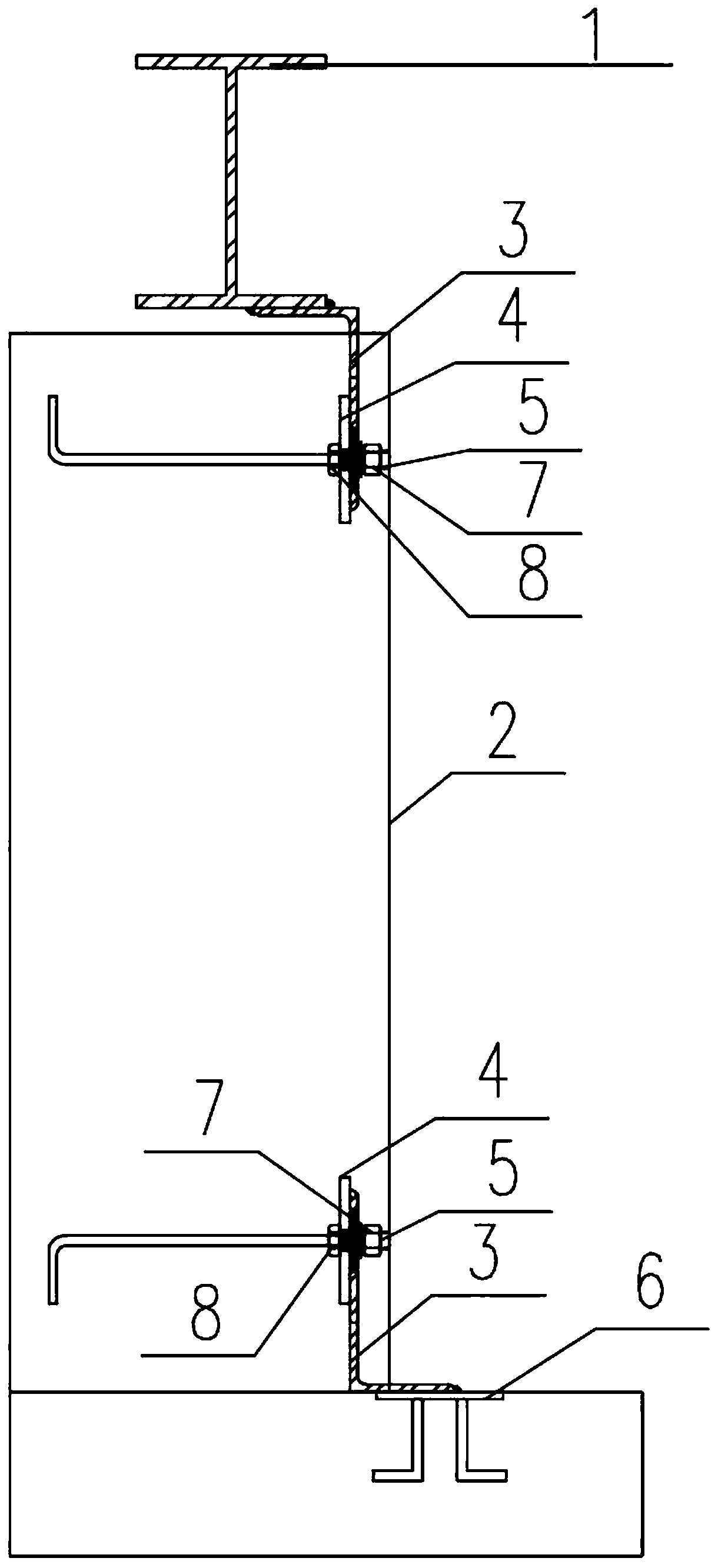

[0019] As shown in the figure, the following steps are used for construction:

[0020] (1) A galvanized steel anchor plate 4 with a transverse slide groove is pre-embedded in the center of the upper and lower ends during the processing and production of the ALC wall panel 2 of the outer wall;

[0021] (2) After the ALC wall panel 2 of the exterior wall is installed at the designated position, the upper end is welded to the steel beam with the angle steel connector 3 with a longitudinal chute;

[0022] (3) The upper end of the ALC wall panel 2 of the outer wall slides into the galvanized steel anchor plate with a horizontal chute embedded in the wall panel with a bolt cap 8. The steel plate anchor plate 4 is reinforced with the external angle steel connector 3 with longitudinal chute;

[0023] (4) The lower end of the ALC wall panel 2 on the outer wall is welded with the angle steel connector 3 with a longitudinal chute and the pre-embedded part 6 embedded in the floor;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com