Prefabricated beam component adjustable supporting system and application method thereof

A support system and adjustable technology, which is applied to the on-site preparation of building components, pillars, building structures, etc., can solve the problem of not fully considering the disassembly or expansion of the support structure, convenient storage and transportation, and insufficient consideration of the lateral stability of the support structure. Problems such as structural safety and stability, inability to adjust, etc., achieve the effect of reducing the space required for storage, increasing the overall stability, and facilitating disassembly or replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

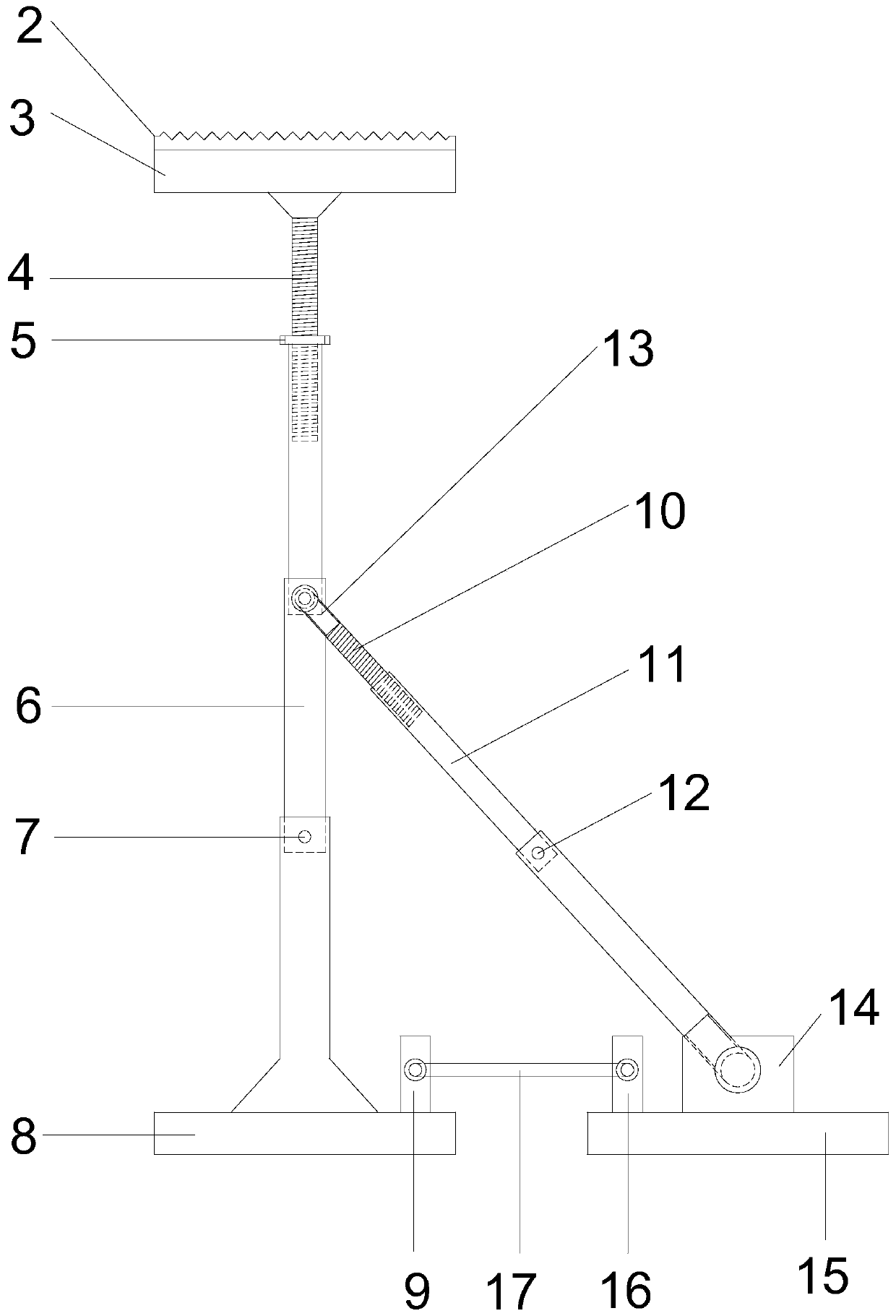

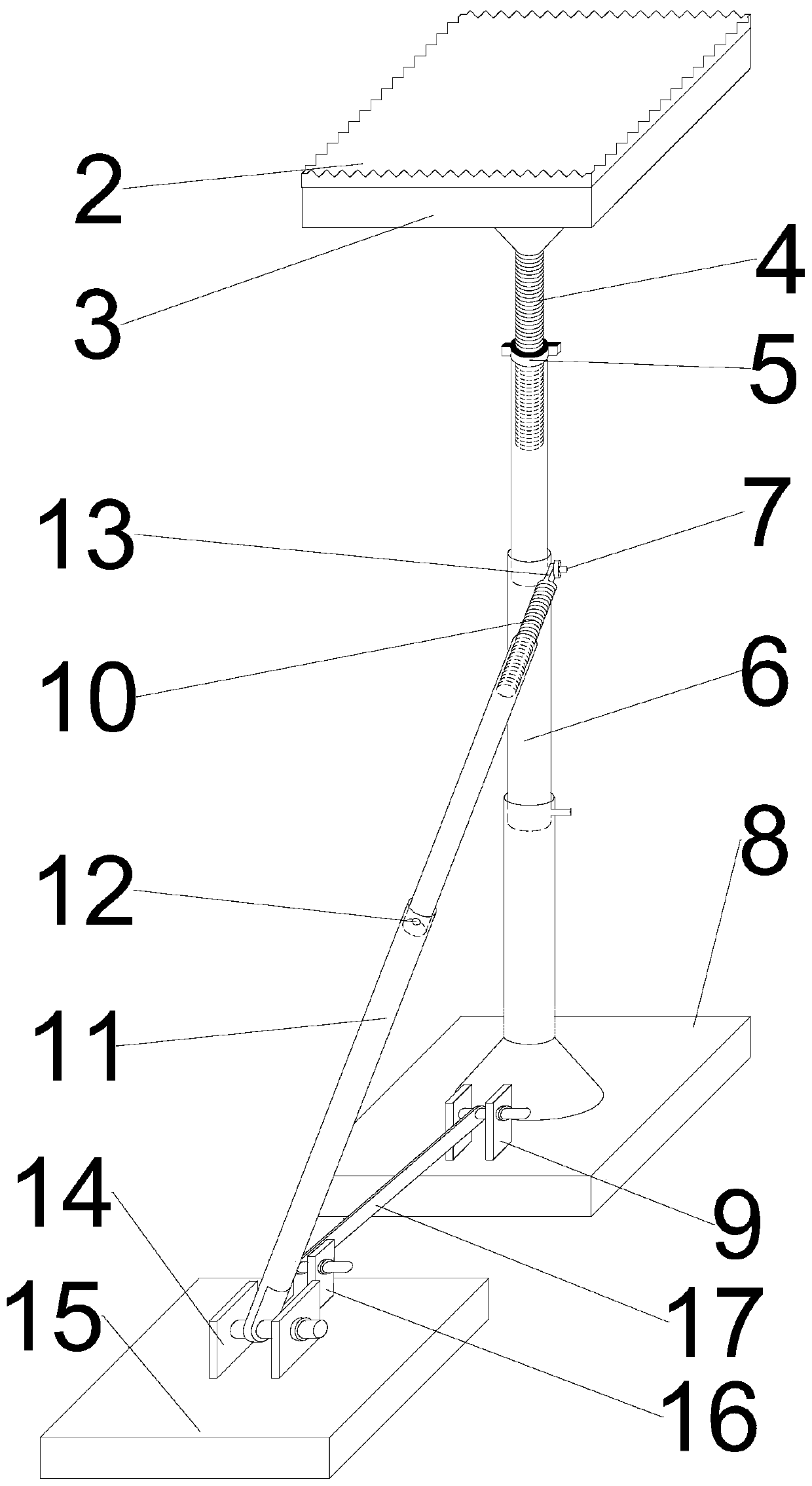

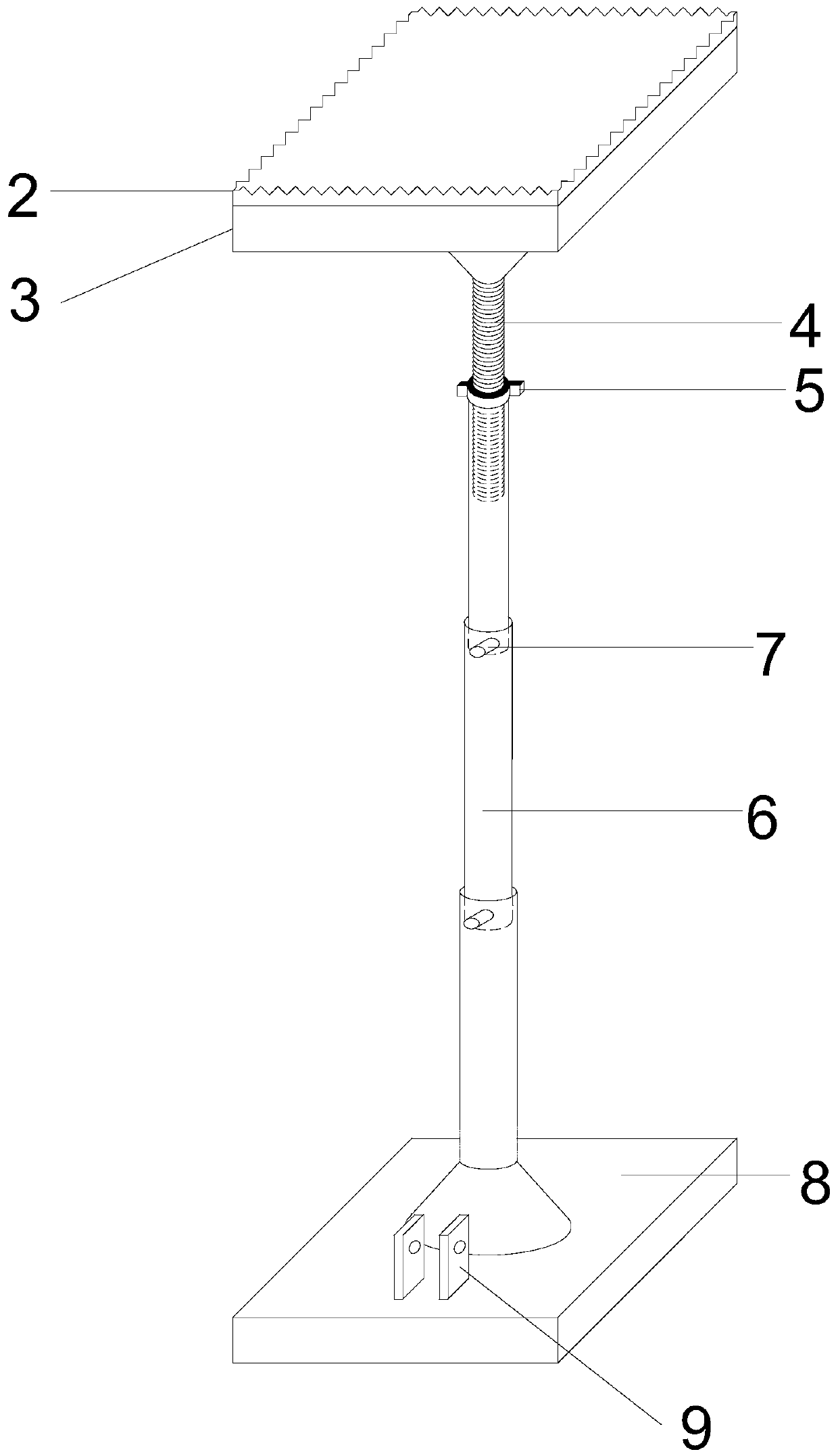

[0031] In this embodiment, an adjustable support system of a prefabricated beam member, such as Figure 1-5 As shown, it includes at least two groups of adjustable support members, and each group of adjustable support members has the same structure. The adjustable support members include a support surface, a vertical support assembly, an oblique support assembly and a connection assembly, and a prefabricated beam member 1 is placed on the support surface. , the vertical support assembly is welded and fixedly installed on the lower part of the support surface, the vertical support assembly, the oblique support assembly and the connection assembly are connected in pairs to form a triangular stable structure, and the placement directions of adjacent adjustable support members are perpendicular to each other; The vertical support assembly includes a first screw rod 4 , a first telescopic rod 6 and a first bottom steel plate 8 , and the oblique support assembly includes a second scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com