Multi-split system containing double enhanced vapor injection compressors

A multi-line system, jet enthalpy increase technology, applied in compressors, compressors with reversible cycles, air conditioning systems, etc. Control precision and jet effect, improve overall performance, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

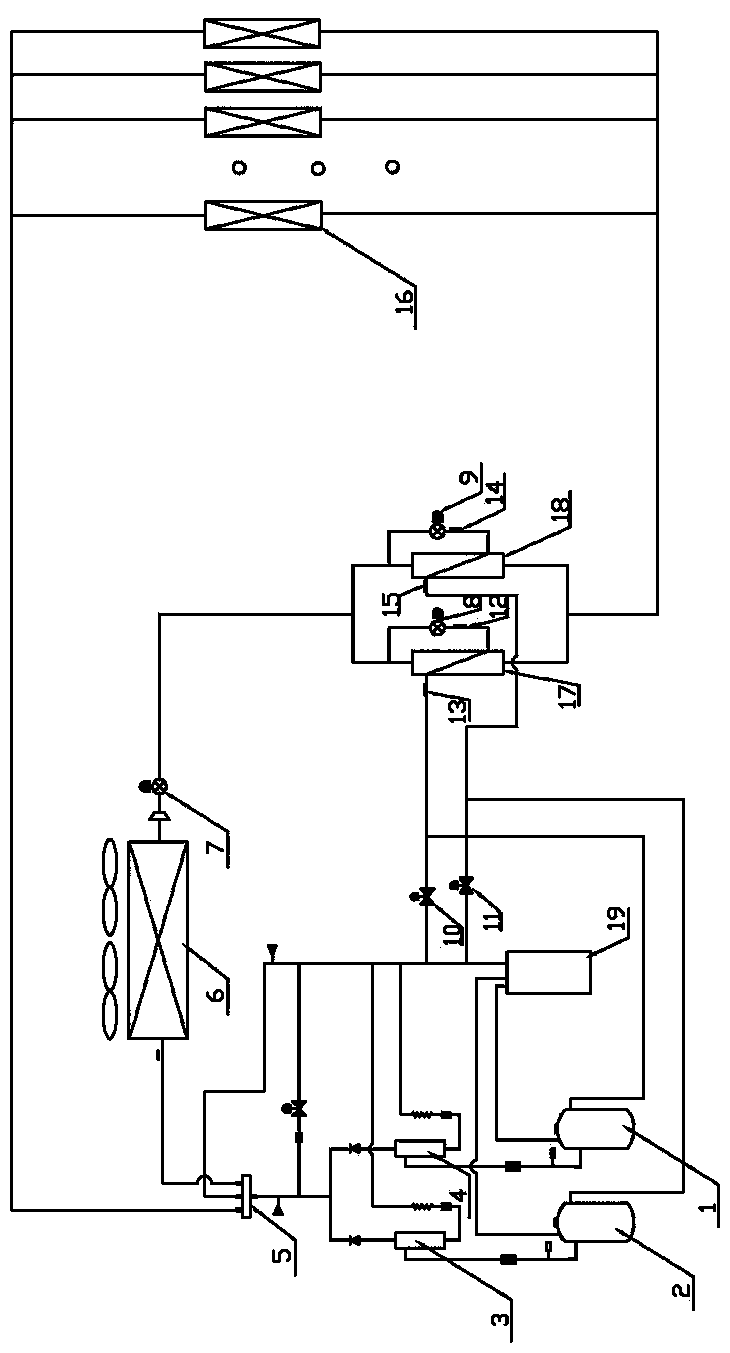

[0017] Such as figure 1 shown.

[0018] A multi-connected system with double-jet enthalpy-increasing compressors, including compressor I1 and compressor II2. The two compressors are air injection enthalpy compressors. The compressor I1 and the compressor II2 are connected in parallel after passing through the oil separator I4 and the oil separator II3 respectively, and then connected to the D port of the four-way valve 5 . Port C of the four-way valve 5 is connected to port E of the four-way valve 5 after passing through the outdoor heat exchanger 6 , the electronic expansion valve III7 , the control system and the indoor heat exchanger 16 in sequence. The S ports of the four-way valve 5 are respectively connected to the suction ports of the two compressors after passing through the gas-liquid separator 19 .

[0019] The control system includes a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com