Tuff blasting blast hole arrangement structure and detonation method

A technology of tuff and blast hole, which is applied in the field of tuff blasting blast hole arrangement structure and detonation, which can solve the problems of rock breaking, rock not being too large, rock not being too broken, etc., and achieve the effect of reducing the volume of rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

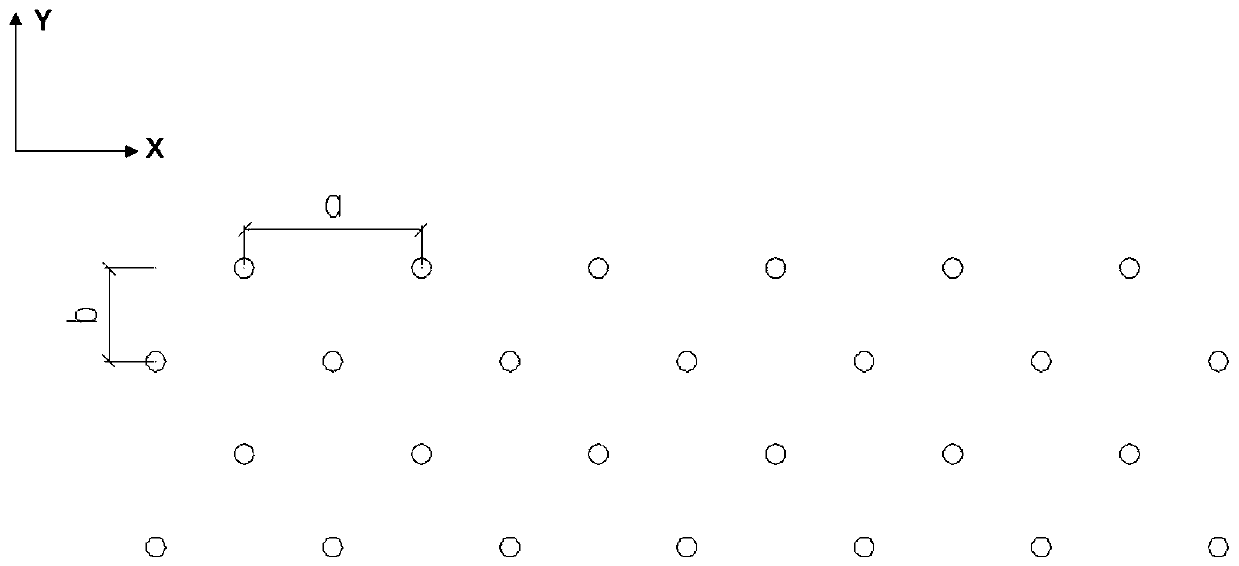

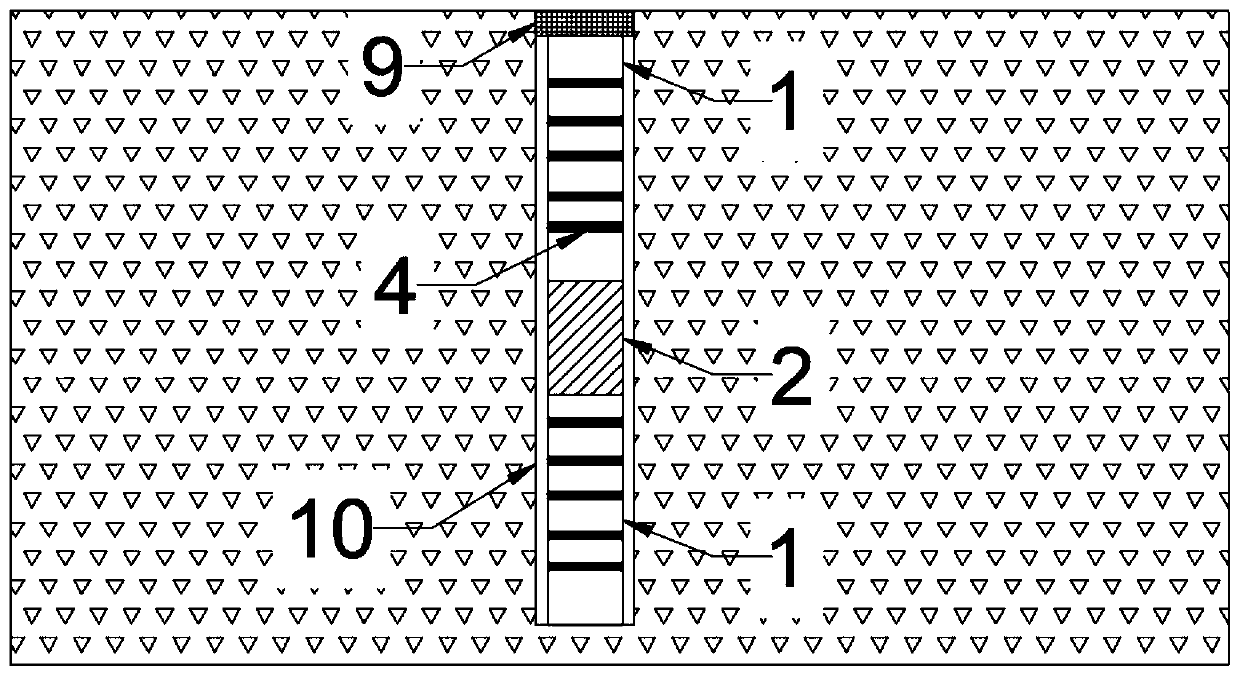

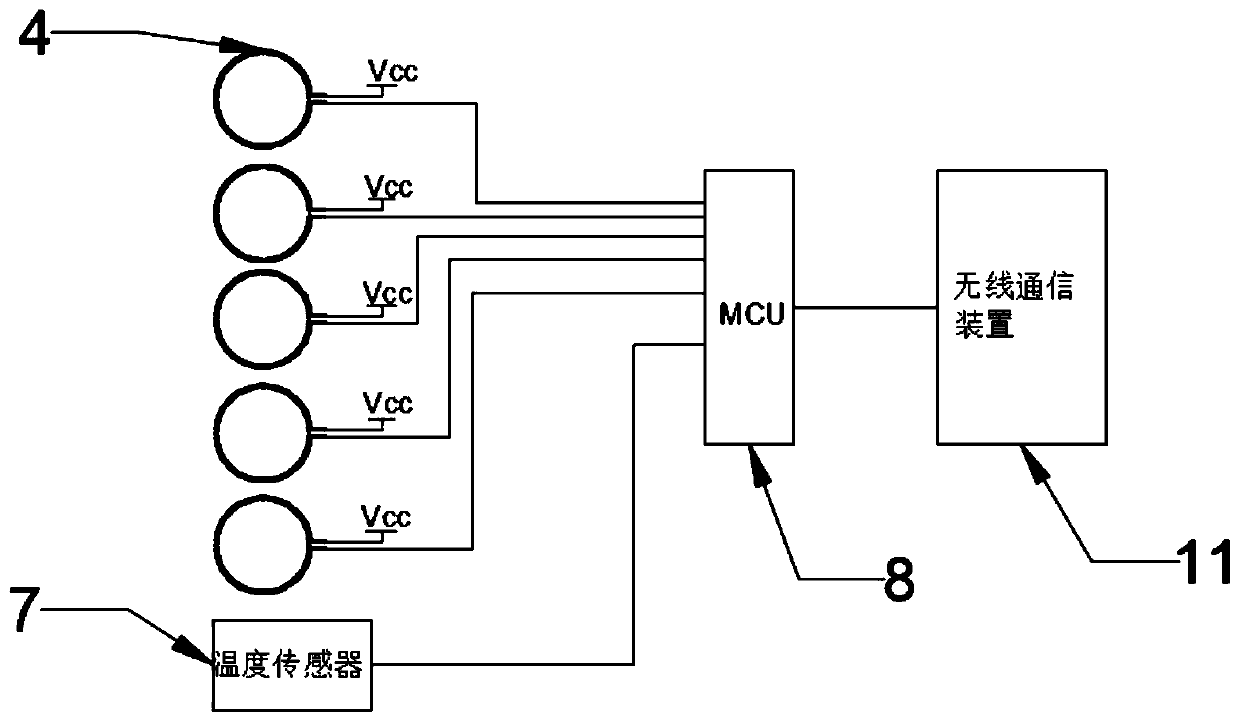

[0038] Implementation Example 1: Reference Figure 1 to Figure 6 , A tuff blasting blasthole arrangement structure, comprising: blastholes 10, the blastholes 10 form an array of more than 2*2, the row and column spacing of blastholes 10 are the same, and two adjacent rows of blastholes 10 have 1 / 2 in the horizontal direction. The dislocation of the 2-column spacing, the gun holes 10 spaced one row apart from each other are aligned in the transverse direction, and each gun hole 10 is filled with the medicine roll 1.

[0039] The present invention uses an array of more than 2*2 blastholes 10, and places a smaller-equivalent pill roll 1 in each blasthole 10 instead of placing a large-equivalent pill roll 1 in one blasthole 10, and the pill roll 1 is placed at a single point The released energy is small, to avoid the tuff crushing, and the tuff is broken by stress waves generated by the blasting of multiple blastholes in the 10 array of blastholes, and the large pieces of tuff are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com