Backfill soil thickness control instrument and using method thereof

A technology for thickness control and backfilling, which is applied to instruments, measuring instruments, and mechanical thickness measurement. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

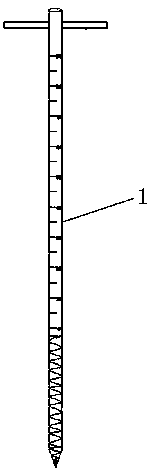

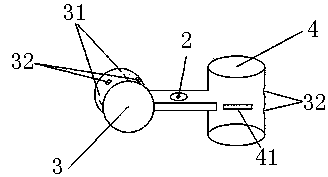

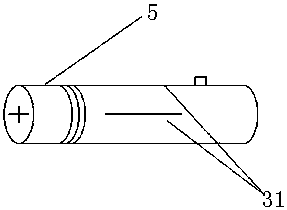

[0021] Such as Figure 1-4 Shown: an instrument for controlling the thickness of backfill soil, which includes a scale rod 1 with a screw end, a fixing device, and a crosshair laser transmitter 5; The horizontal cylinder 3 and the vertical cylinder 4 at the end, the horizontal cylinder is provided with an alignment line 31 and a bolt hole 32 corresponding to the crosshair laser transmitter, and the crosshair laser transmitter is fixed in the horizontal cylinder; The vertical cylinder body is provided with a scale hole 41, and a scale rod with a helical end is fixed in the vertical cylinder body.

[0022] A method for using a backfill thickness control instrument, comprising the steps of:

[0023] Step 1: Drill the scale rod vertically into the soil layer until the zero scale line is flush with the surface of the soil layer;

[0024] Step 2: Fix the crosshair laser transmitter to the fixing device. There are alignment lines on the surface of the fixing device and the crosshai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com