Energy storage cabinet for ships

A ship and energy storage technology, which is applied to electrical components, substation/distribution device shells, and anti-seismic equipment. The effect of rocking shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

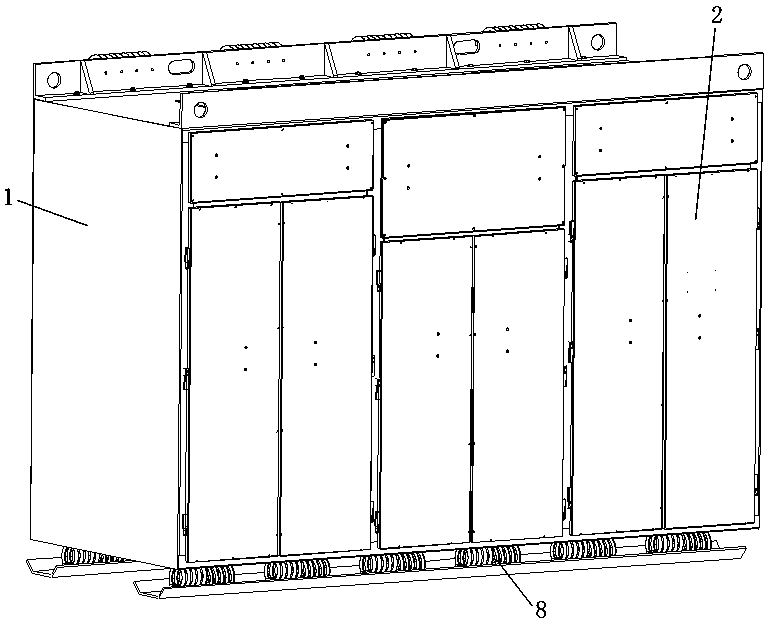

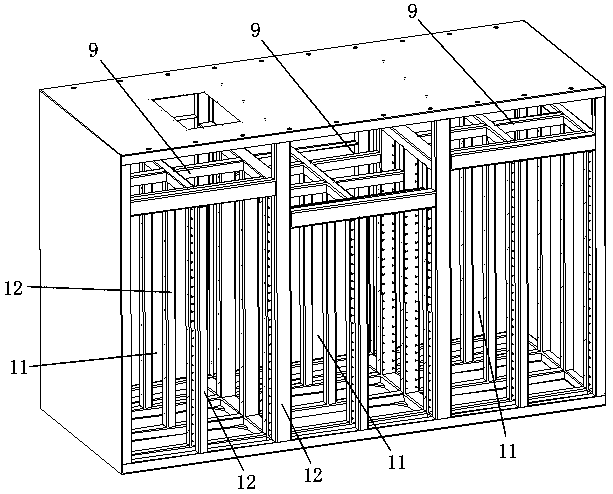

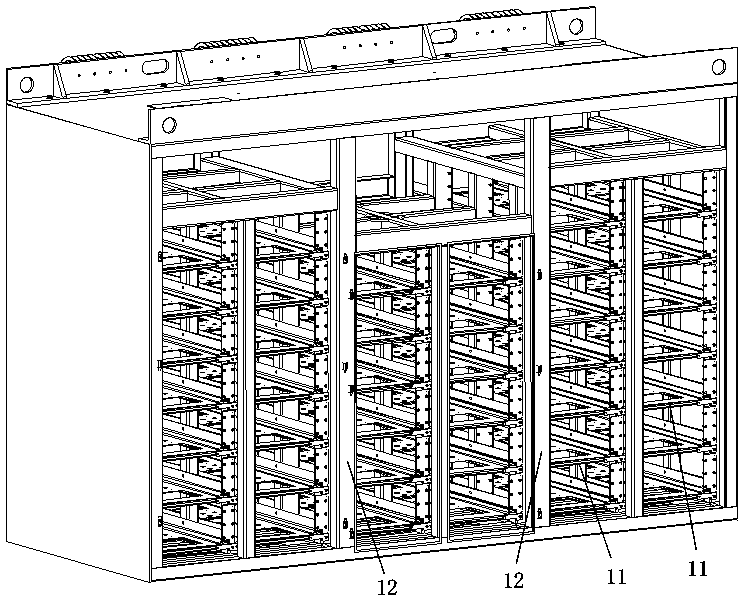

[0028] like Figure 1~4 As shown, an energy storage cabinet for ships is provided, which includes a rectangular parallelepiped cabinet body 1 and a door panel closing the cabinet body. A plurality of capacitor trays 3 are stacked up and down in the compartment, and guide rails 4 with an L-shaped cross-section are installed on the sides of each capacitor tray 3 in the length direction. On the guide rail 4 and can slide along the guide rail, the end of the guide rail 4 deep into the compartment is installed with a pressing block 5 for inserting the capacitor tray. The pressing block includes an upturned part 51 with a distance from the surface of the guide rail 4, and the distance overlaps with the capacitor tray. The thickness of 31 is adapted, and the outlet of the compartment 11 is provided with mounting blocks 6 at both ends of the width direction of each capacitor tray 3 to fix the capacitor tray. One end of the mounting block is connected to the column, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com