Wire stripping and cutting machine

A technology of cutting machine and cutting mechanism, which is applied to equipment, cable installation devices, electrical components, etc. for cutting/disconnecting cables. It can solve the problems of difficulty in cable management, knotting and winding, etc., to simplify the structure and facilitate cable management. , The effect of reducing the difficulty of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

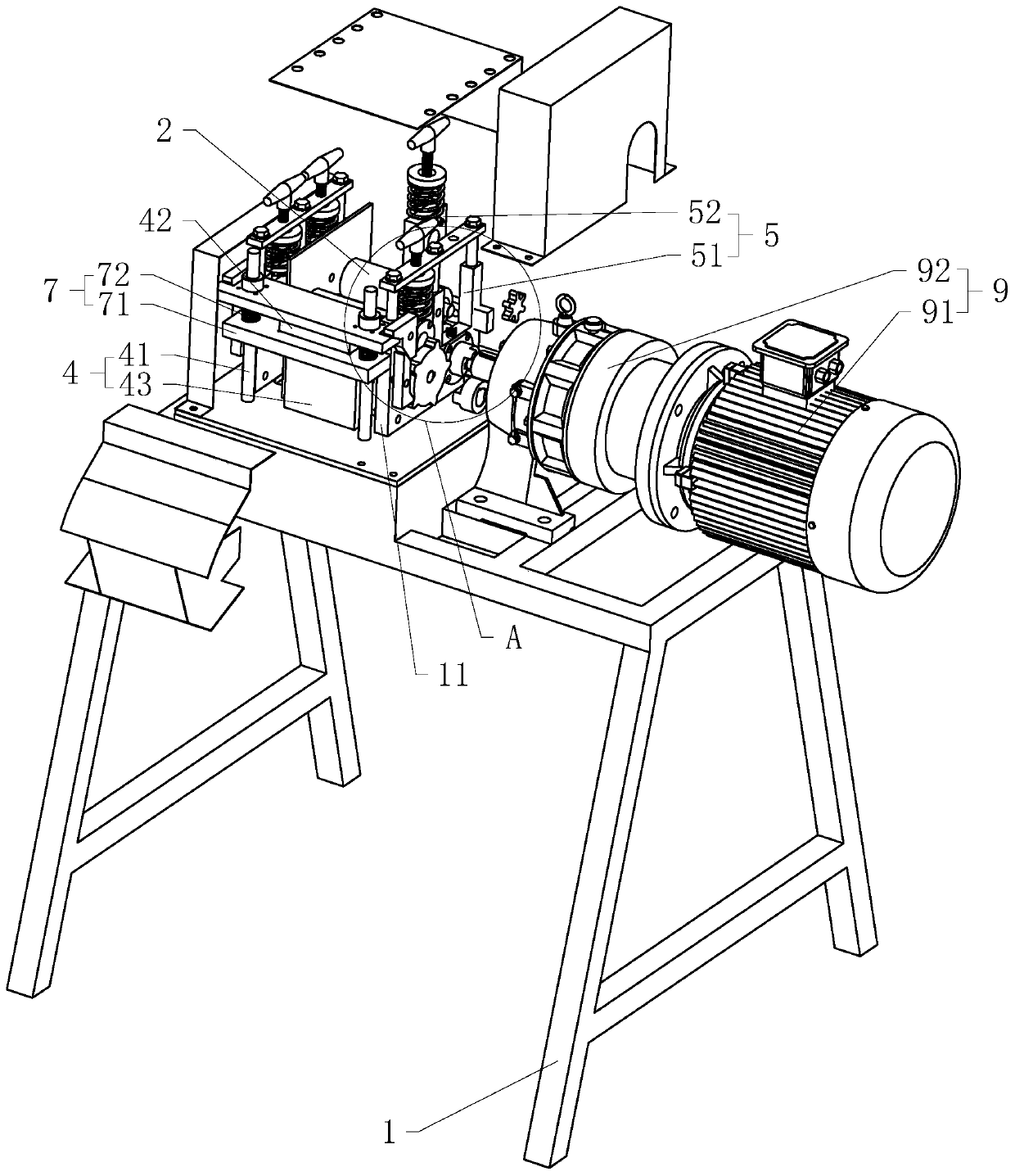

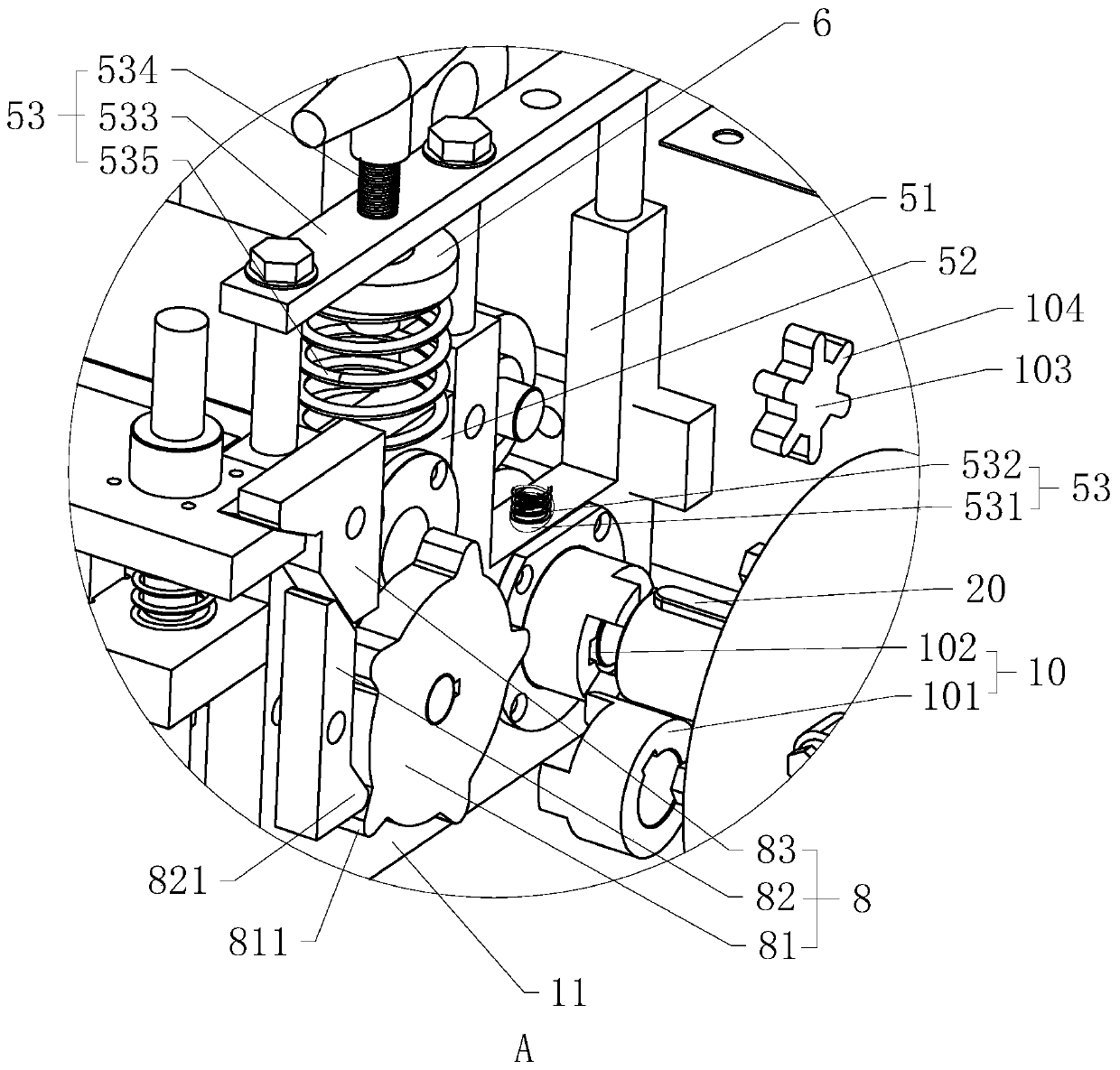

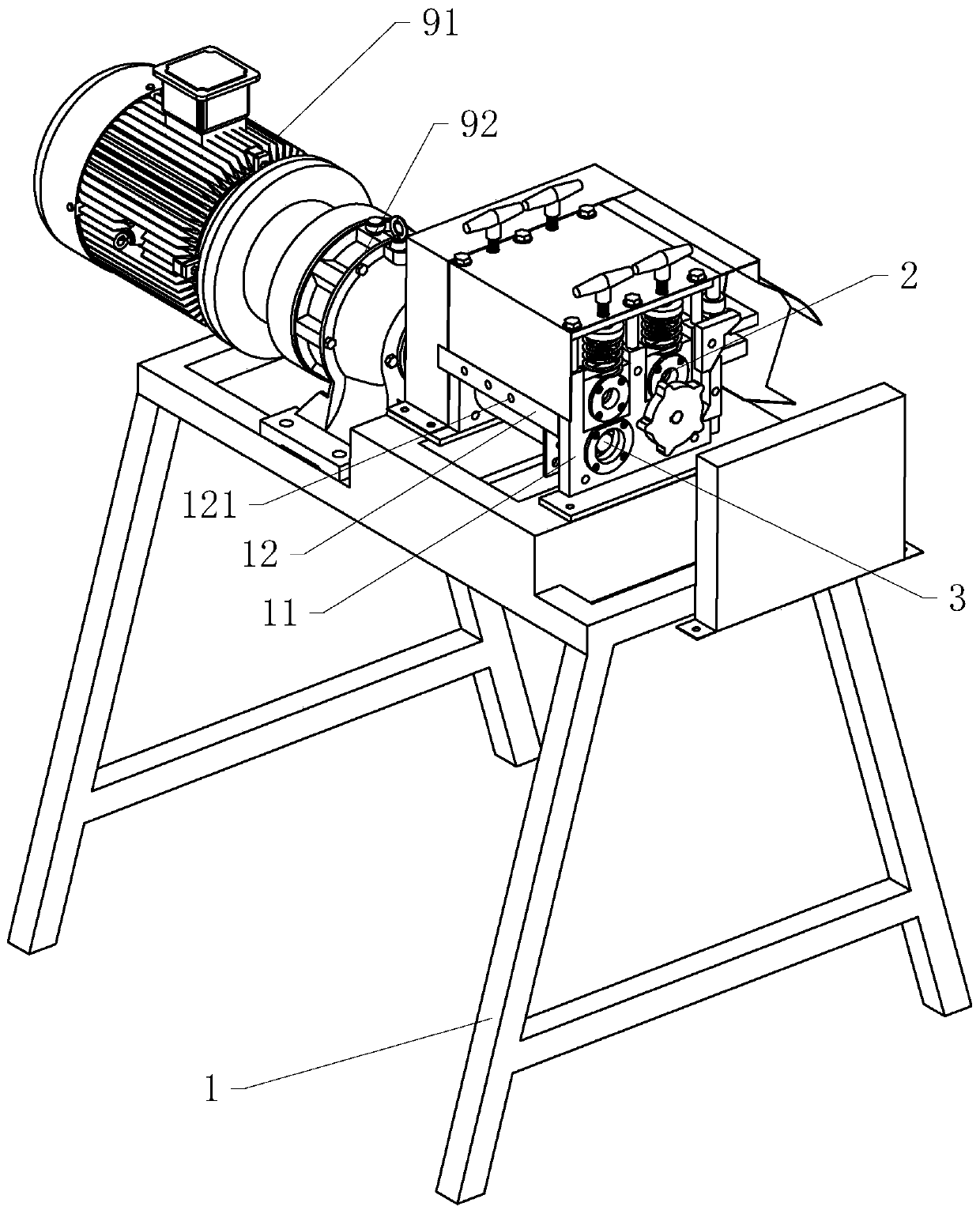

[0033] Such as figure 1 As shown, a wire stripping and cutting machine includes a frame 1, an upper nip roller 2, a lower nip roller 3, a cutting mechanism 4, a linkage mechanism 8, and a driving mechanism 9, and the working surface of the frame 1 is detachably installed with bolts. Two side plates 11 are installed on one side of the frame 1 with an incoming board 12 through bolts, and the two ends of the incoming board 12 are respectively fixed with the two side boards 11; 121, the cable inlet 121 is arranged from left to right in the process of increasing in diameter; the upper nip roller 2 and the lower nip roller 3 work in pairs, and this case is provided with at least two sets of upper and lower nip rollers 3, each of the lower nip rollers The pinch rollers 3 are mutually driven in the form of sprockets and chain belts. Multiple sets of upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com