Closestool cover plate disassembling and assembling mechanism

A technology for disassembling and assembling mechanism and toilet cover, which is applied to the seat or cover of toilet, household appliances, sanitary equipment, etc., can solve the problems of easy loosening, poor firmness, limited impact force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

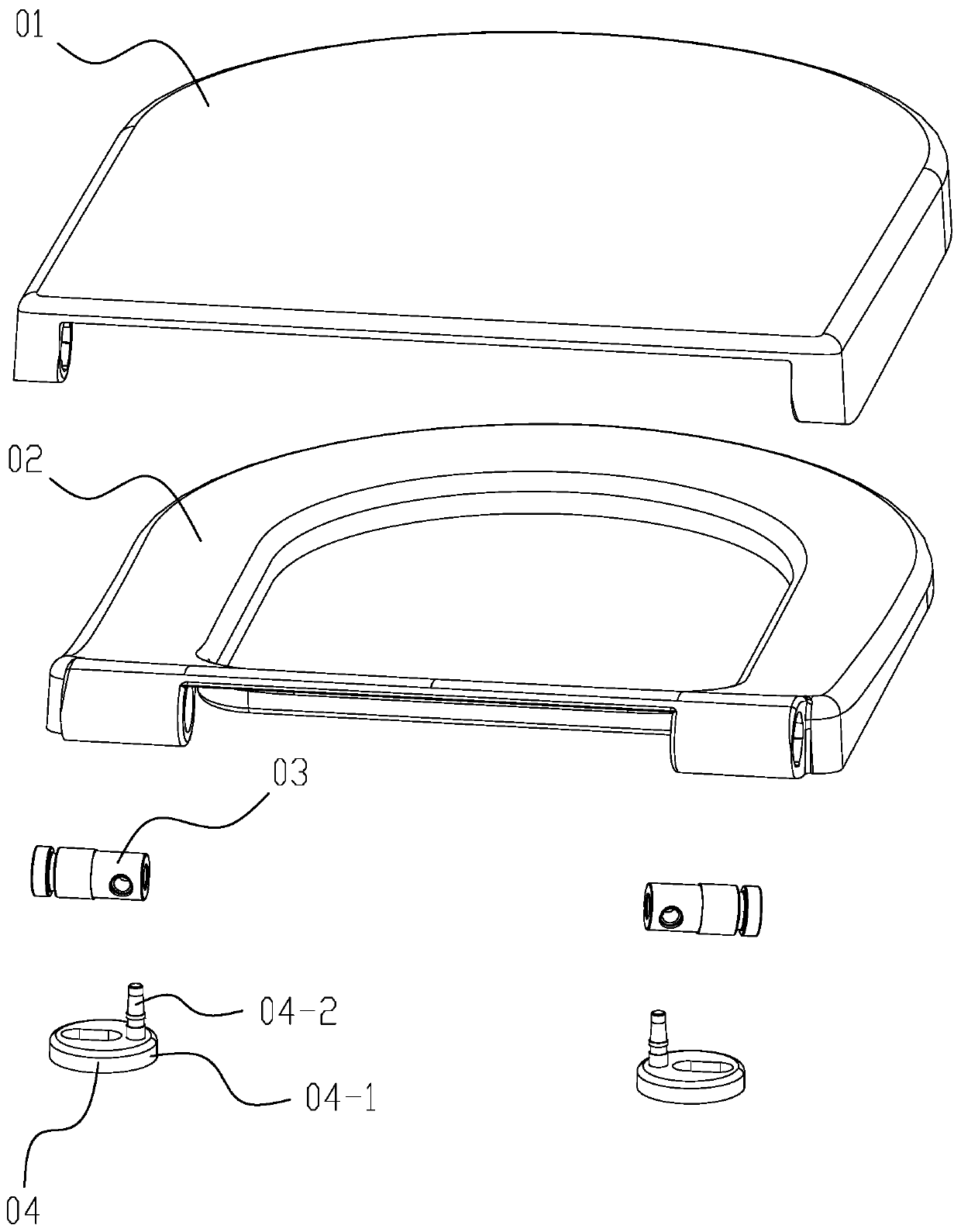

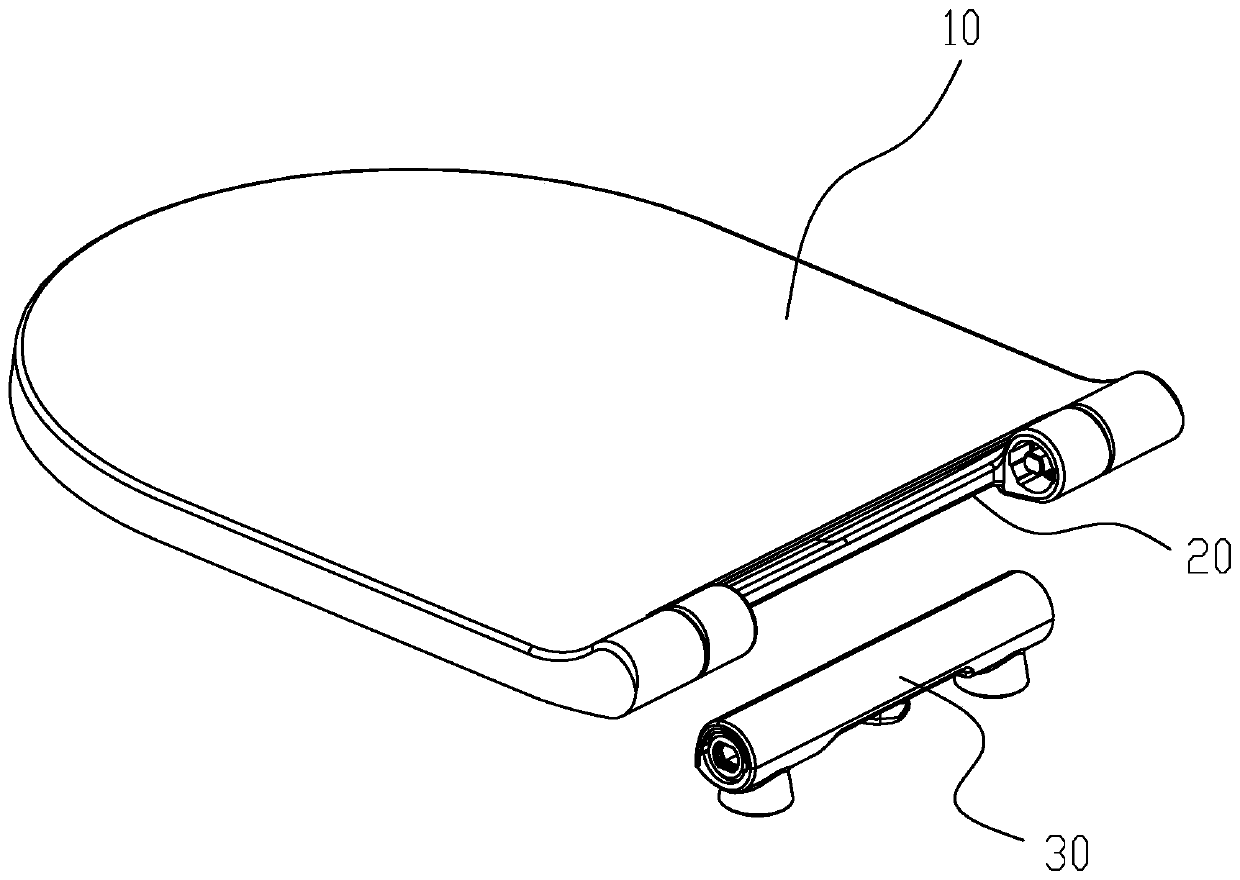

[0025] Please refer to figure 2 and image 3 , The toilet cover includes an upper cover 10 and a seat ring 20, and the connecting parts on both sides of the rear end of the upper cover are respectively rotatably connected with the connecting parts on both sides of the rear end of the seat ring. The toilet cover disassembly mechanism 30 of the present invention is used to connect the toilet cover and the toilet seat (not shown), so that the toilet cover can be quickly installed on the toilet seat, or quickly disassembled from the toilet seat down.

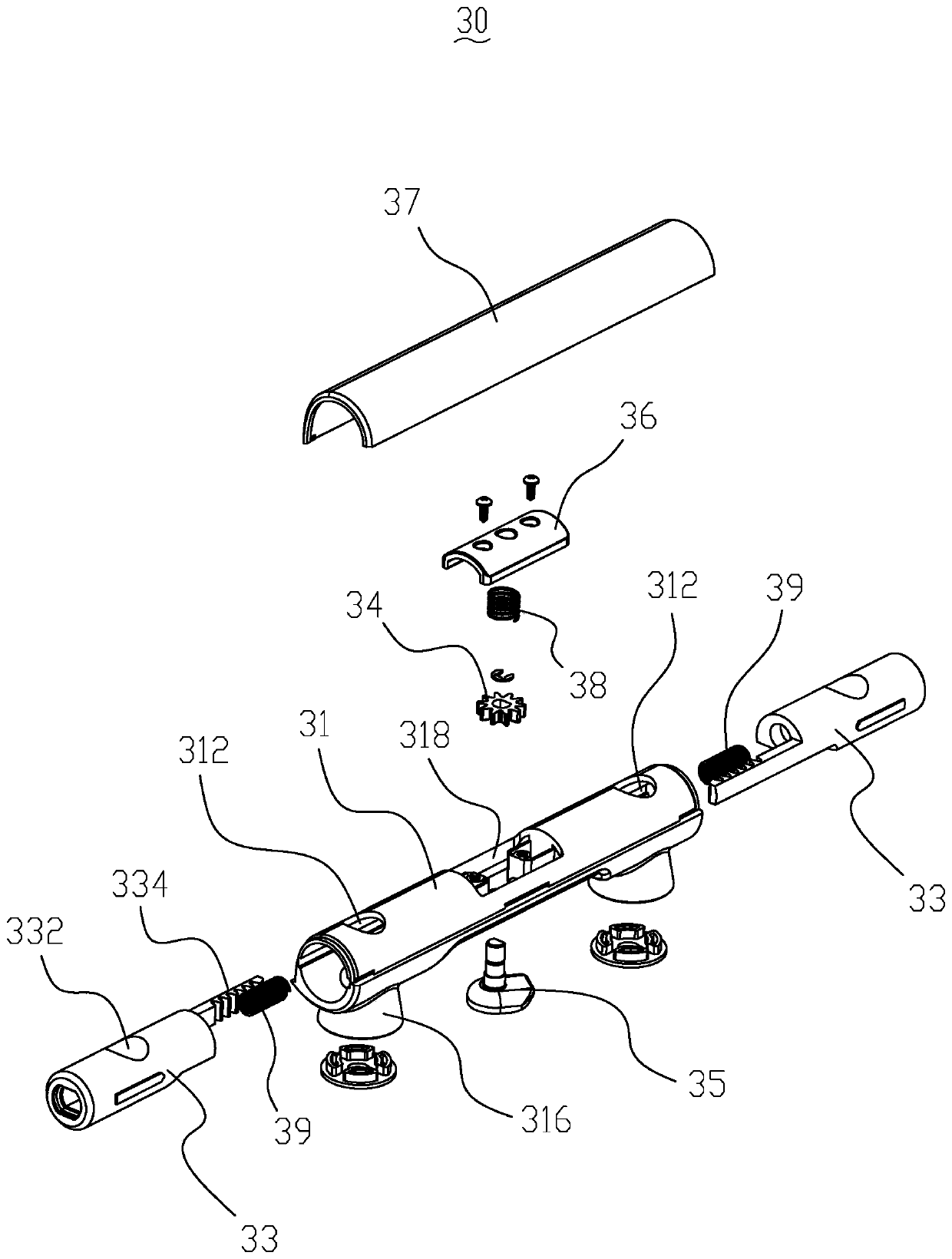

[0026] Please refer to Figure 4 and Figure 5 , the dismounting mechanism 30 includes a shaft sleeve 31, the shaft sleeve 31 is locked on the toilet seat 40 by two bolts 32, the two ends of the shaft sleeve 31 are symmetrically provided with vertically penetrating installation holes 312, the installation The hole 312 is preferably radially and vertically penetrated, so that the centerline of the mounting hole is perpendicular ...

Embodiment 2

[0038] Please refer to Figure 7 and Figure 8 , the difference between the second embodiment and the first embodiment has the following points: First, the connector 33 is not an independent component, but an assembly, including the damper 33-1 and the bushings 33-2, 33 covering the damper -1 The damper is arranged in the bushing 31, the bushing 33-2 is provided with a push-pull rod 334, and the push-pull rod 334 is axially pulled to make the connecting piece 33 move axially, if the damper 33-1 If the push-pull rod 334 is directly installed, the bushing 33-2 can be omitted; secondly, the switch 35 is covered with a drive gear 352, which is meshed with the gear 34 for transmission, and the gear 34 corresponds to the push-pull rod 334 one by one. Switch 35, drive gear 352 rotate together, drive gear 34 to rotate, make push-pull bar 334 move; During installation or disassembly, the connecting piece 33 shrinks inwards to make way for the bolt 32 , and the bolt 32 can be installe...

Embodiment 3

[0041] Please refer to Figure 9 and Figure 10 The difference between the third embodiment and the second embodiment is: first, the connecting piece 33 also includes a connecting shaft 33-3, the connecting shaft 33-3 and the damper 33-1 are axially plugged together, and the cover plate is installed and locked In this state, the end of the connecting shaft 33-3 stretches out from the sleeve 31, and the connecting shaft 33-3 is provided with a relief through hole 332 corresponding to the installation hole 312; secondly, the switch 35 drives the gear 34 to rotate, and the gear 34 drives the push-pull rod 334 to move, and the upper cover 36 covers the gear 34; thirdly, the mounting hole 312 penetrates downward through the support base 316, and the support base 316 is internally screwed with a spacer 311, and the bolt 32 passes through the spacer 311, the head of the bolt is pressed against the pad.

[0042] The connector 33 of this solution adds a connecting shaft 33-3. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com