Preventive levelling active-underpinning device and construction method

A preventive and active technology, applied in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as construction complexity, inability to accurately quantify the adverse effects of foundation pits, and achieve the effect of avoiding impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

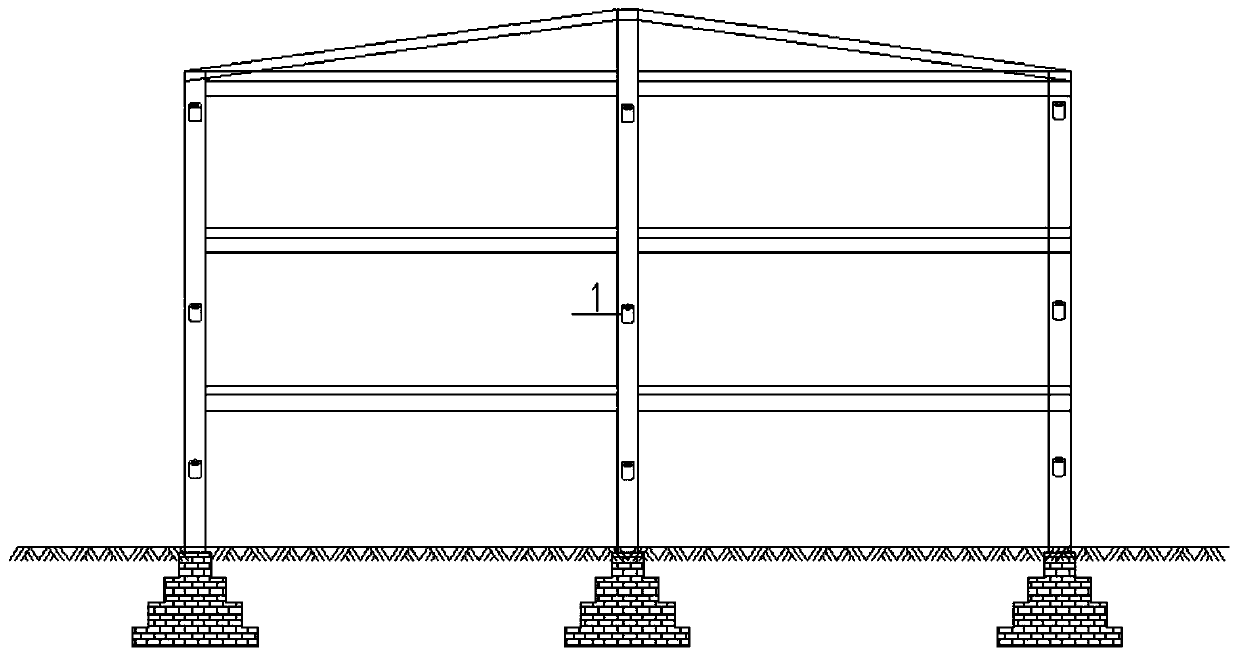

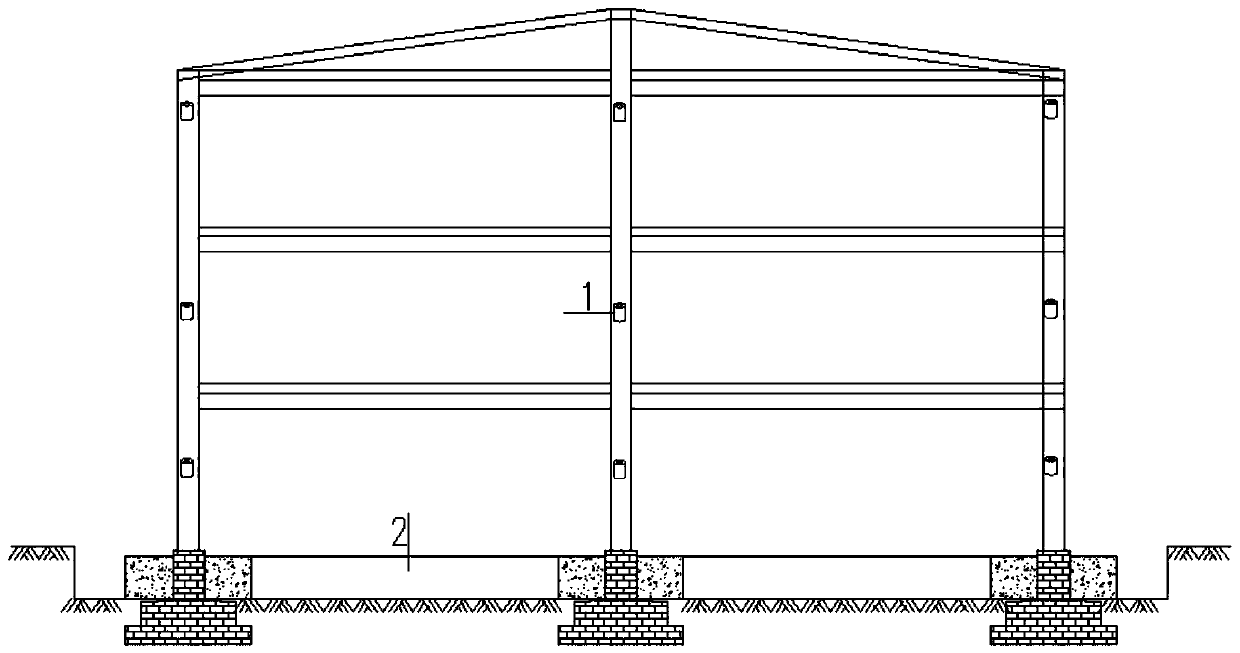

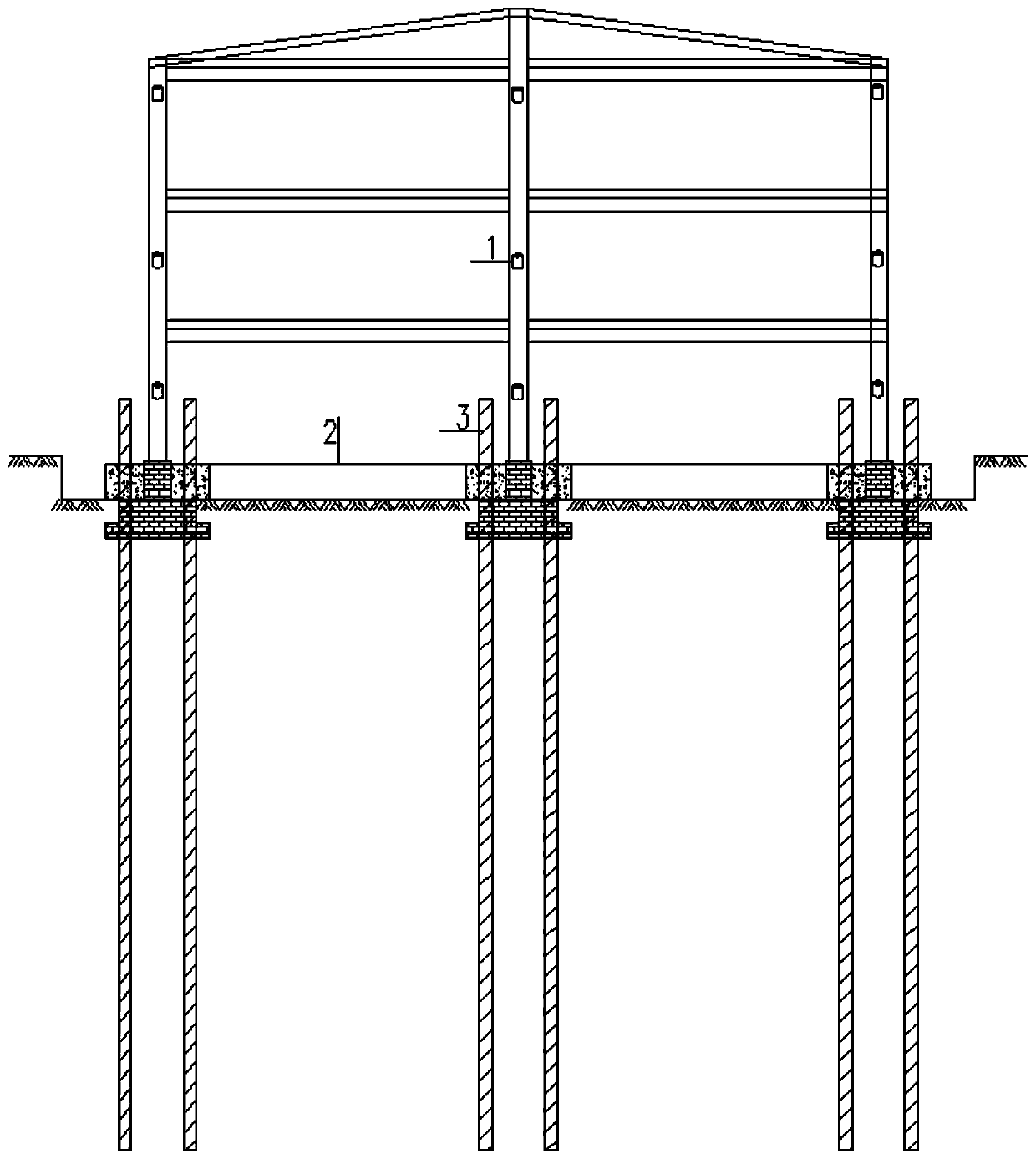

[0037] Figure 1-Figure 4 It shows a preventive levelable active underpinning device, which includes a real-time monitoring device 1, a horizontal tray structure 2, a vertical reaction force structure 3 and an active leveling structure 4,

[0038] The upper end of the vertical reaction force structure 3 passes through the horizontal tray structure 2 and is connected to the output end of the active leveling structure 4,

[0039] Both the real-time monitoring device 1 and the active leveling structure 4 are electrically connected to a controller.

[0040] The real-time monitoring device 1 includes sensors and storage devices, and the monitoring contents include settlement, inclination, and crack status.

[0041] The horizontal tray structure 2 is at least one of steel and reinforced concrete.

[0042] The horizontal pallet structure 2 is a pile type or a column type.

[0043] The vertical reaction force foundation 3 is at least one of steel and reinforced concrete.

[0044] ...

Embodiment 2

[0046] Figure 1-Figure 4 A construction method of a preventive leveling active underpinning device is shown, the method includes the following steps:

[0047] Step 1, install and debug the real-time monitoring device 1, install the real-time monitoring device 1 on the building, and monitor the health status of the whole process of the building;

[0048] Step 2, constructing the horizontal pallet structure 2, and fixing the horizontal pallet structure 2 on the lower end of the building;

[0049] Step 3, constructing the vertical reaction force foundation 3, passing one end of the vertical reaction force foundation 3 through the horizontal pallet structure 2;

[0050] Step 4, install and debug the active leveling device 4, install the active leveling device 4 on the upper end of the horizontal pallet 2, and the building enters the levelling active underpinning state,

[0051] Step 5: Analyze the changes of the real-time monitoring data through the controller, judge the state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com