Spaceflight transmission mechanism analysis method based on fault data

A technology of transmission mechanism and analysis method, applied in database distribution/replication, database indexing, engine testing, etc., can solve problems affecting the authenticity and reliability of fault data results, insufficient robustness of management system, unsafe fault system, etc., to achieve Strong safety and practicability, less chance of false alarms, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

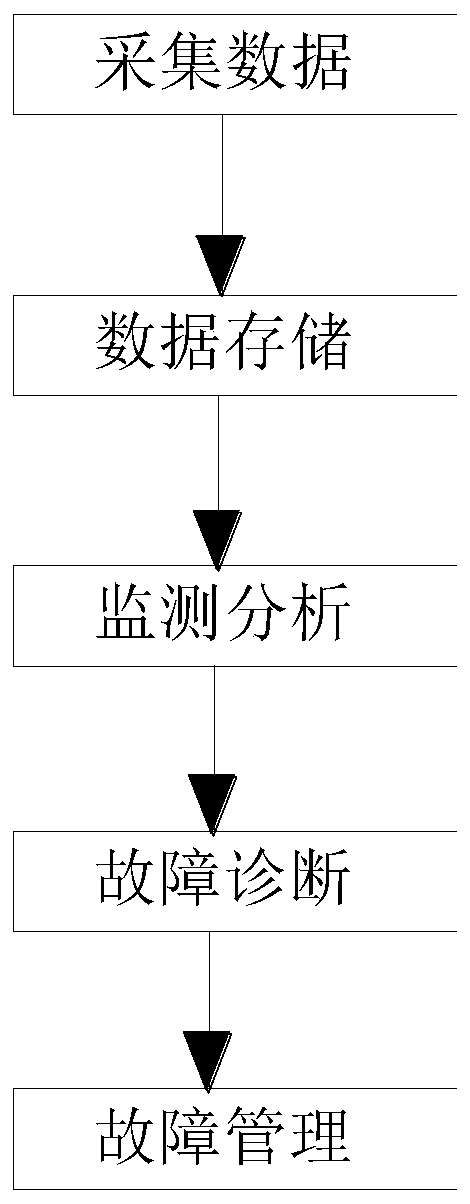

[0047] see figure 1 , a kind of aerospace transmission mechanism analysis method based on fault data, described method comprises the following steps:

[0048] S1: Collect data, collect the speed of the inner and outer rotors of the aero-engine, and generate two key-phase signals to trigger the sampling of the corresponding vibration points;

[0049] S2: Data storage. During online monitoring, the set database is divided into configuration database and unit database. Each transmission mechanism corresponds to a unit database, and the configuration database stores relevant configuration information;

[0050] S3: Monitoring and analysis, comprehensive monitoring and analysis of the vibration signal of the transmission mechanism, divided into two modes: real-time monitoring and historical query, and the analysis results can be displayed on the monitoring host screen;

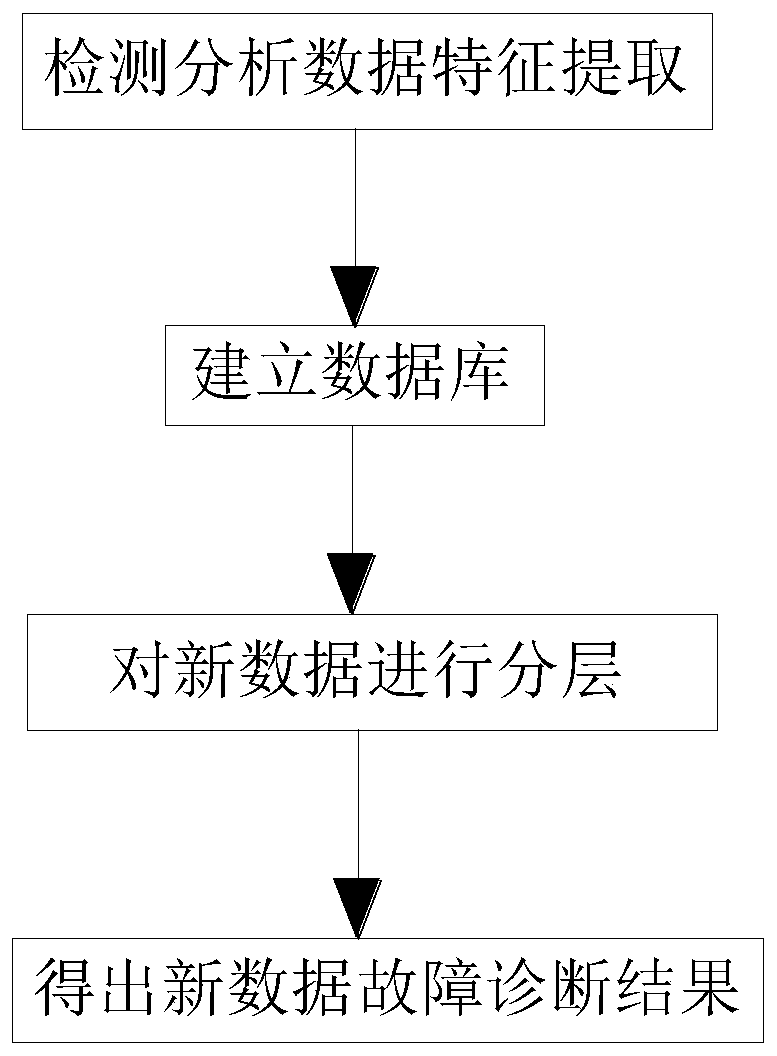

[0051] S4: Fault diagnosis, including a, detection and analysis data feature extraction; b, establishment of dat...

Embodiment 2

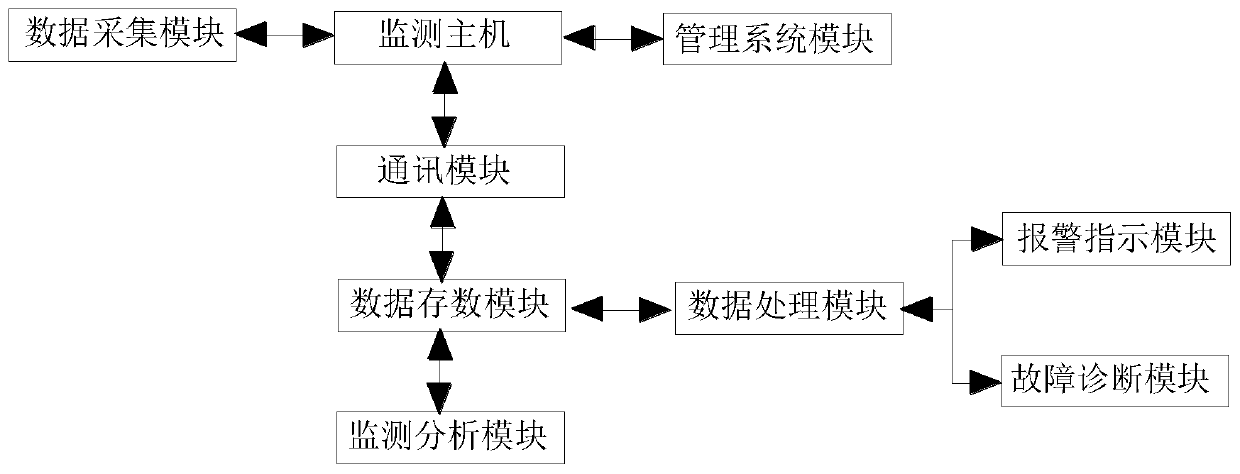

[0059] see Figure 2-3 A fault data analysis system adopted by an aerospace transmission mechanism analysis method based on fault data, comprising a data acquisition module and a detection host; the data acquisition module includes a sensor and a data collector; the monitoring host is provided with a management system module, a communication modules, data processing modules, data storage modules, monitoring and analysis modules, fault diagnosis modules, and alarm indication modules; the sensors are eddy current sensors and piezoelectric acceleration sensors; the eddy current sensors are arranged on the rotor rolling bearings of the transmission system, The vibration of the rolling bearing is measured, and the piezoelectric acceleration sensor is arranged on the inner wall of the transmission casing to measure the vibration of the casing; the data collector collects the speed and vibration signals of the aviation transmission system.

[0060] The management system module includ...

Embodiment 3

[0072] The difference from Embodiments 1 and 2 is that the data storage module is a database, and the SQLServer database is used to manage data and data backup. The database is responsible for receiving the data sent by the acquisition module, and corresponding to the query and update data requests of the data processing module.

[0073] The model of the eddy current sensor is 3300XL-11mm eddy current sensor; the piezoelectric acceleration sensor is Kistler9640A50 sensor.

[0074] This system is actually developed in C# language on the Visual Studio 2015 platform, uses ADO.NET technology to access the database, and cooperates with the SQLServer database to achieve efficient development of the system.

[0075] In addition, the fault diagnosis method is as follows: S1, detection and analysis data feature extraction, data segmentation is first performed during the original data processing, and then feature extraction is performed on each segment of data, and data such as time doma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com