Spring welding structure of motor, winding structure and lens driving motor

A technology of welding structure and winding structure, which is applied in the field of motors, can solve the problems of affecting the axial movement state of the lens group, inconsistent number of winding coils, poor soldering and open circuit, etc., to improve the quality of welding connection, the number of winding coils is consistent, The effect of reasonable location layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

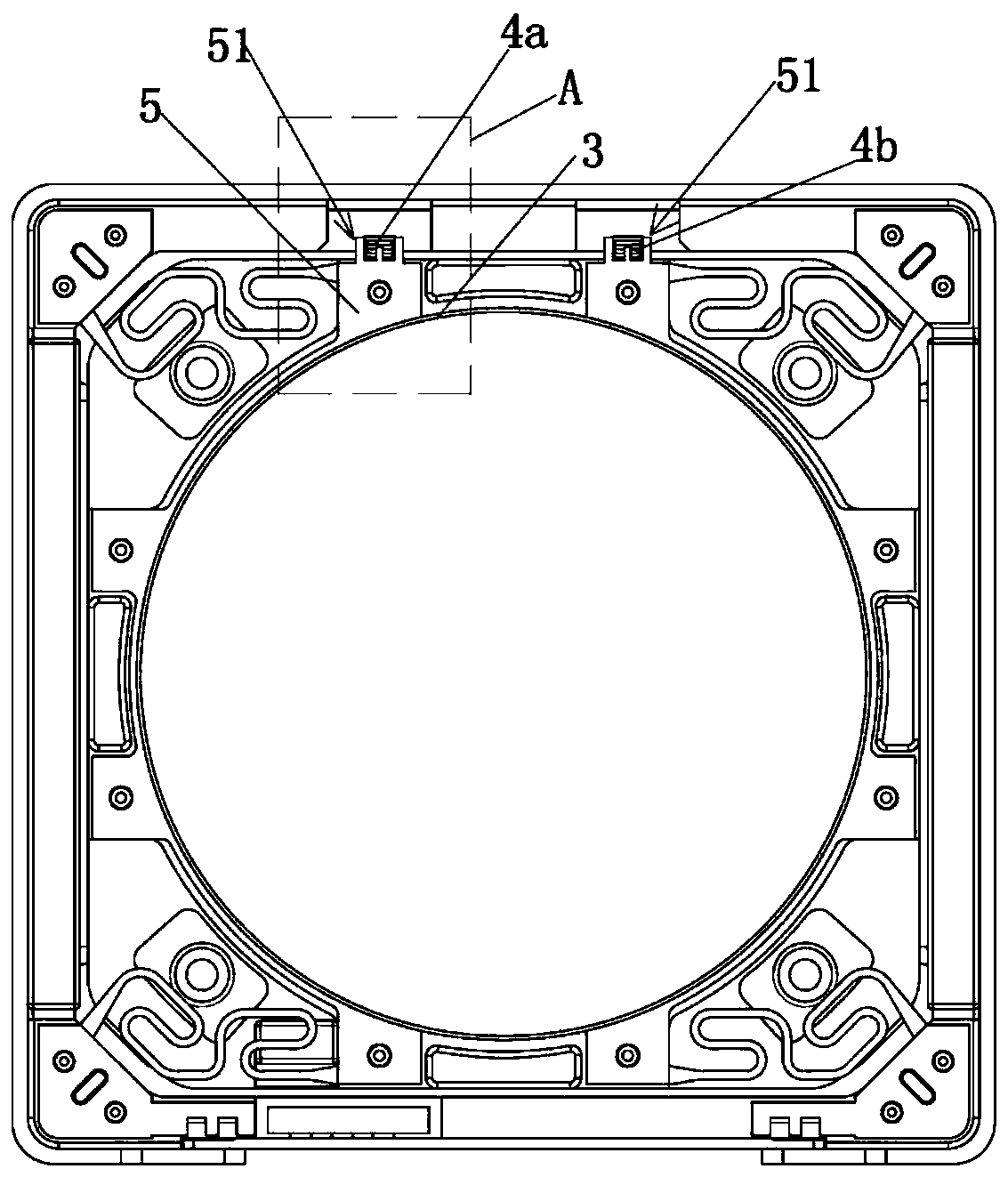

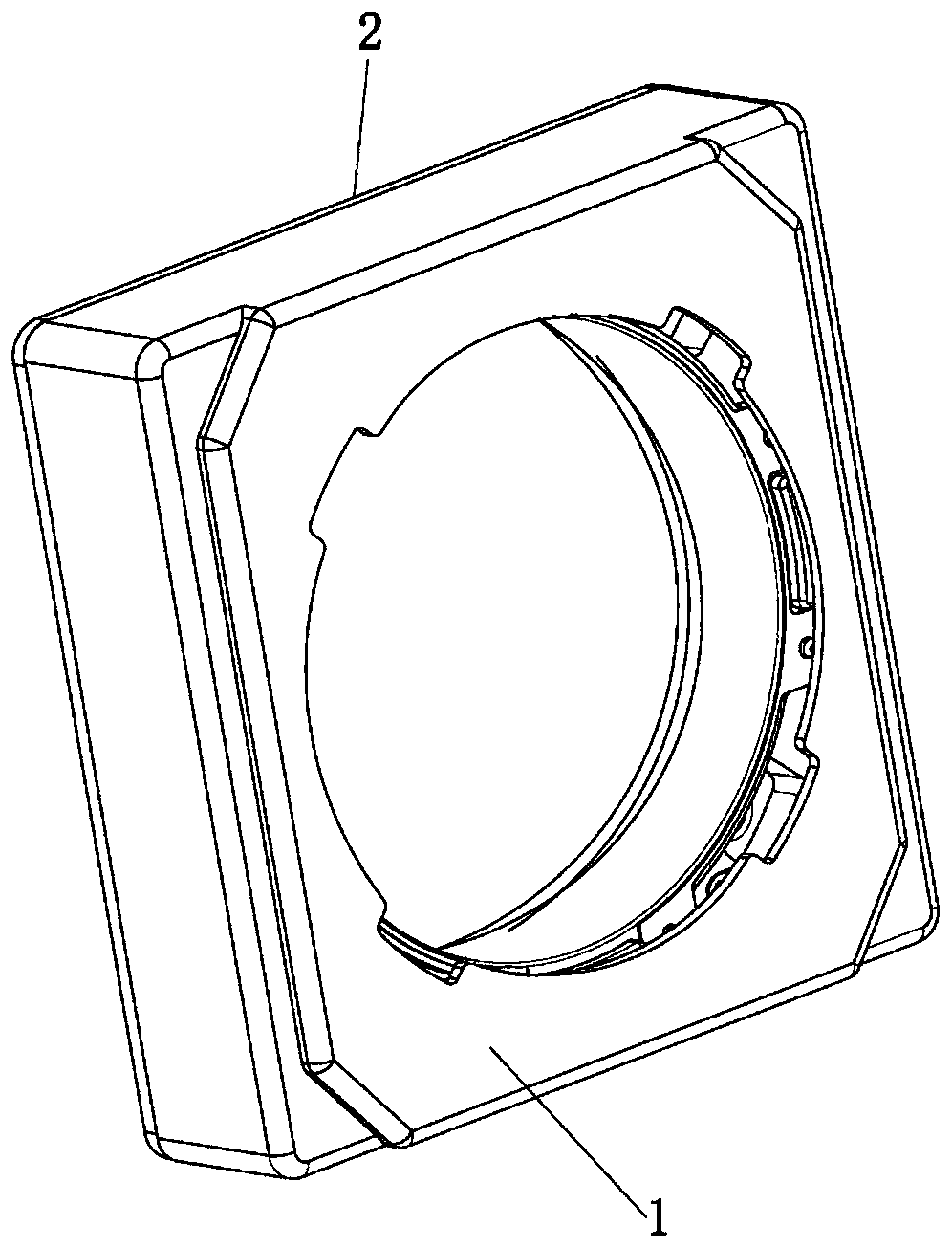

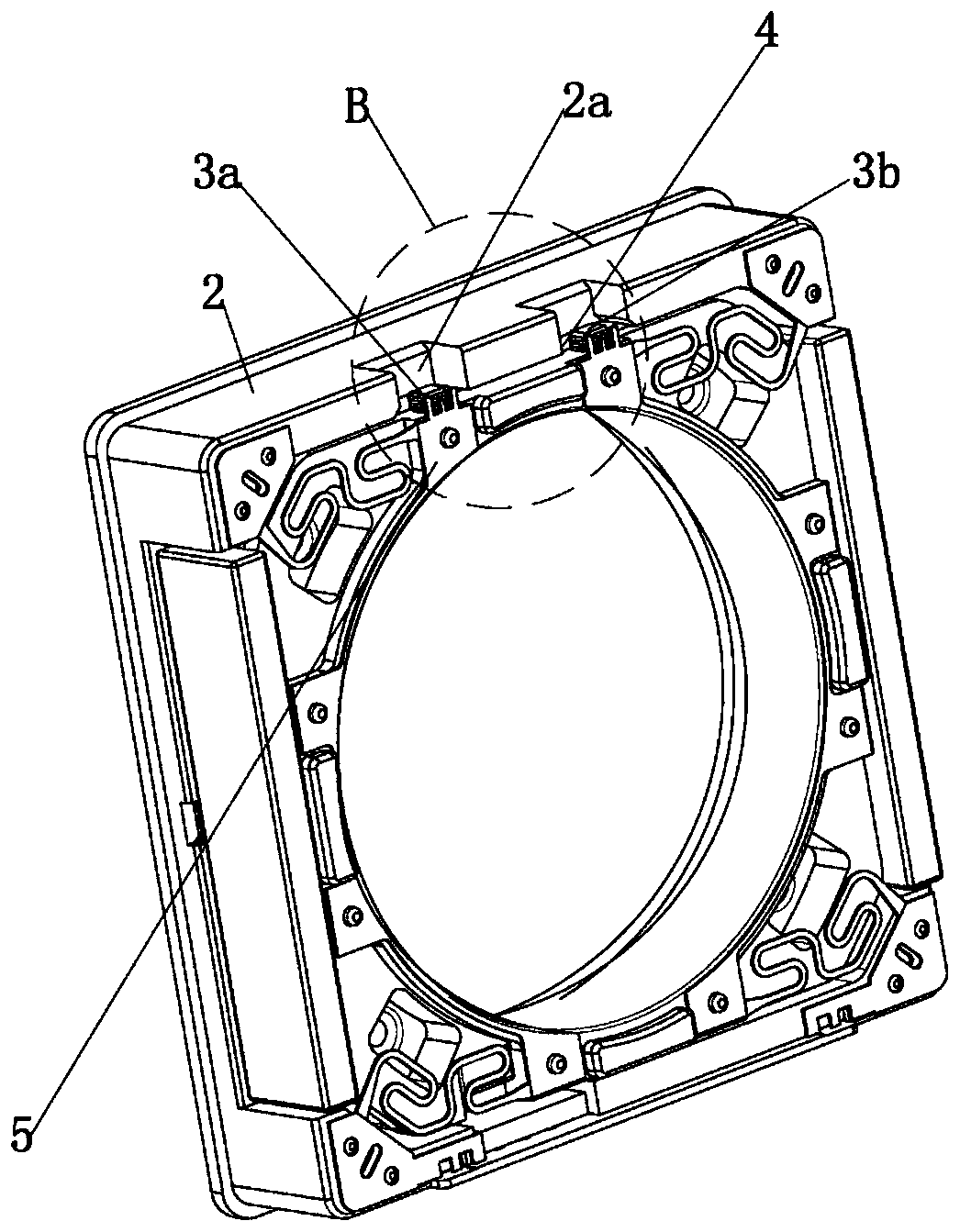

[0027] combine Figure 1-5 As shown, in order to ensure the firmness of the welding, the spring welding structure of the motor is set as follows: the spring sheet 5 has two welding ends 51 respectively welded to connect the first end 4a of the coil and the second end 4b of the coil, and the welding end 51 includes a pair of A connecting pin 51a for soldering connection, and a connecting reinforcing pin 51b between the two connecting pins 51a, a groove filled with solder is formed between the connecting pins 51a, so that the welding end 51 constitutes an "E" shaped structure, making the shape It is more beautiful; the above-mentioned connection and reinforcement foot 51b is in the middle position between the two connection feet 51a; the outer extension of the above-mentioned connection and reinforcement foot 51b is shorter than that of the connection foot 51a.

[0028] Since the connection reinforcement foot 51b is provided between the two connection feet 51a, the welding conta...

Embodiment 2

[0034] This embodiment can refer to Figure 4 A slight modification is made, and the spring welding structure of the motor is set as follows: the spring piece 5 has two welding ends 51 respectively welded to connect the first end 4a of the coil and the second end 4b of the coil, and the welding end 51 includes a pair of connections for welding connection Foot 51a, and two connection reinforcement feet 51b between the two connection feet 51a, a groove filled with solder is formed between the connection feet 51a, so that the welding end 51 forms an "E" shaped structure, making the shape more beautiful; the above connection The reinforcing leg 51b is located in the middle between the two connecting legs 51a; the outer extension of the connecting reinforcing leg 51b is shorter than the outer extension of the connecting leg 51a.

[0035] Since there are two connecting reinforcing feet 51b, the welding contact surface is further enlarged, so that the firmness of the welding is incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com