Sea area pipeline turning section connection construction method

A construction method and pipeline technology, which is applied in sewer pipeline systems, artificial islands, waterway systems, etc., can solve problems such as high cost of steel pipe piles, unstable operating conditions, and complicated construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

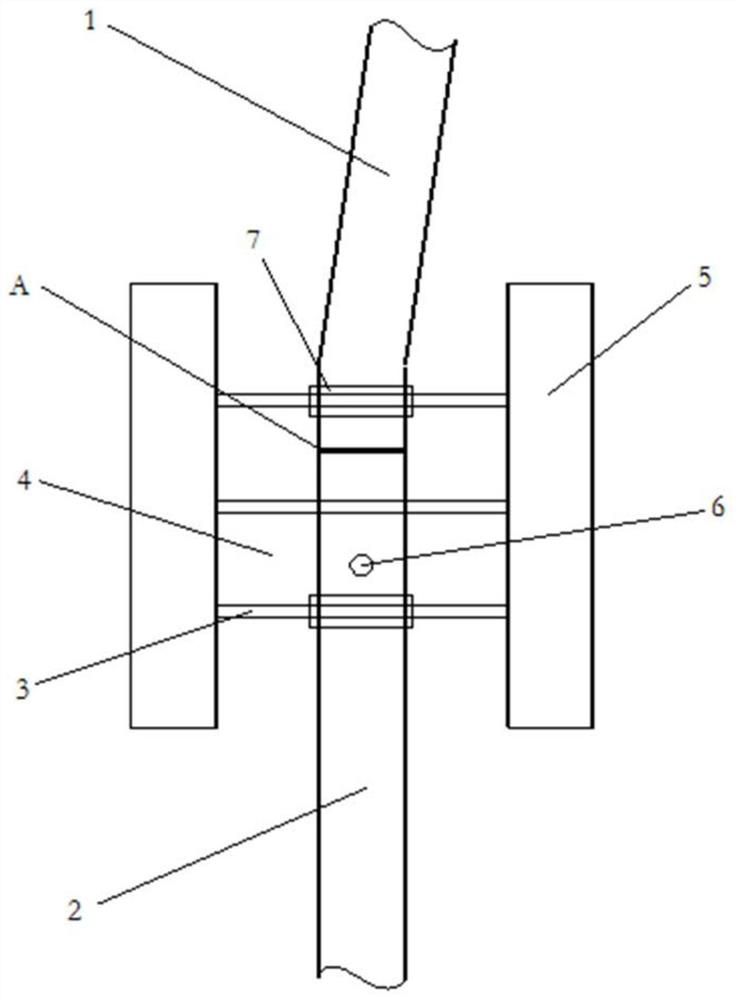

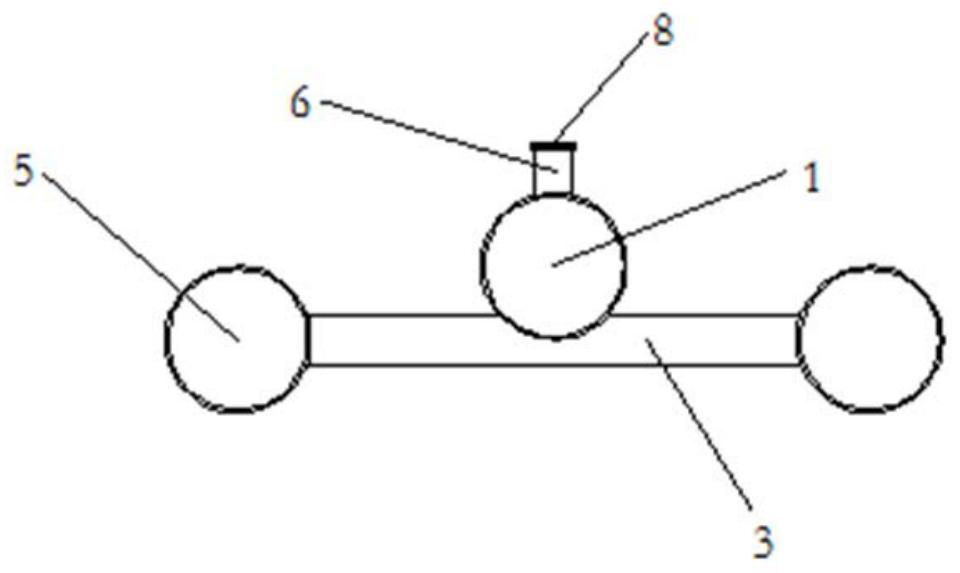

[0030] Embodiment 1, with reference to figure 1 , combined with figure 2 , a sea area pipeline turning section 1 connection construction method, its steps are as follows,

[0031] (1) Construction preparation for the sea area pipeline turning section 1

[0032] a. Seabed trenching: Use grab dredgers to dig out seabed trenches according to the design axis of the sea area pipeline turning section 1;

[0033] b. Welding tee pipe 6: transport the tee pipe 6 and welding equipment to the sinking site of the sea area pipeline turning section 1 by tugboat, and weld the tee pipe 6 to the top of the sea area pipeline turning section 1 through the welding equipment, and the tee The pipe 6 communicates with the sea area pipeline turning section 1;

[0034] c. Prepare a steel pontoon: the steel pontoon includes two buoys 5, and the two buoys 5 are connected by a support bracket;

[0035] (2) Installation of turning section 1 of pipeline in sea area

[0036] a. Connect the steel buoya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com