Assembly of liner and flange for vertical furnace as well as liner and vertical furnace

A vertical furnace and lining technology, which is applied in the direction of furnace components, vertical furnaces, furnaces, etc., and can solve the problem of pollution in the inner space of the treatment tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the present application, similar or corresponding features are indicated by similar or corresponding reference signs. The description of various embodiments is not limited to the examples shown in the figures, and reference numerals used in the detailed description and claims are not intended to limit the described content to the examples shown in the figures.

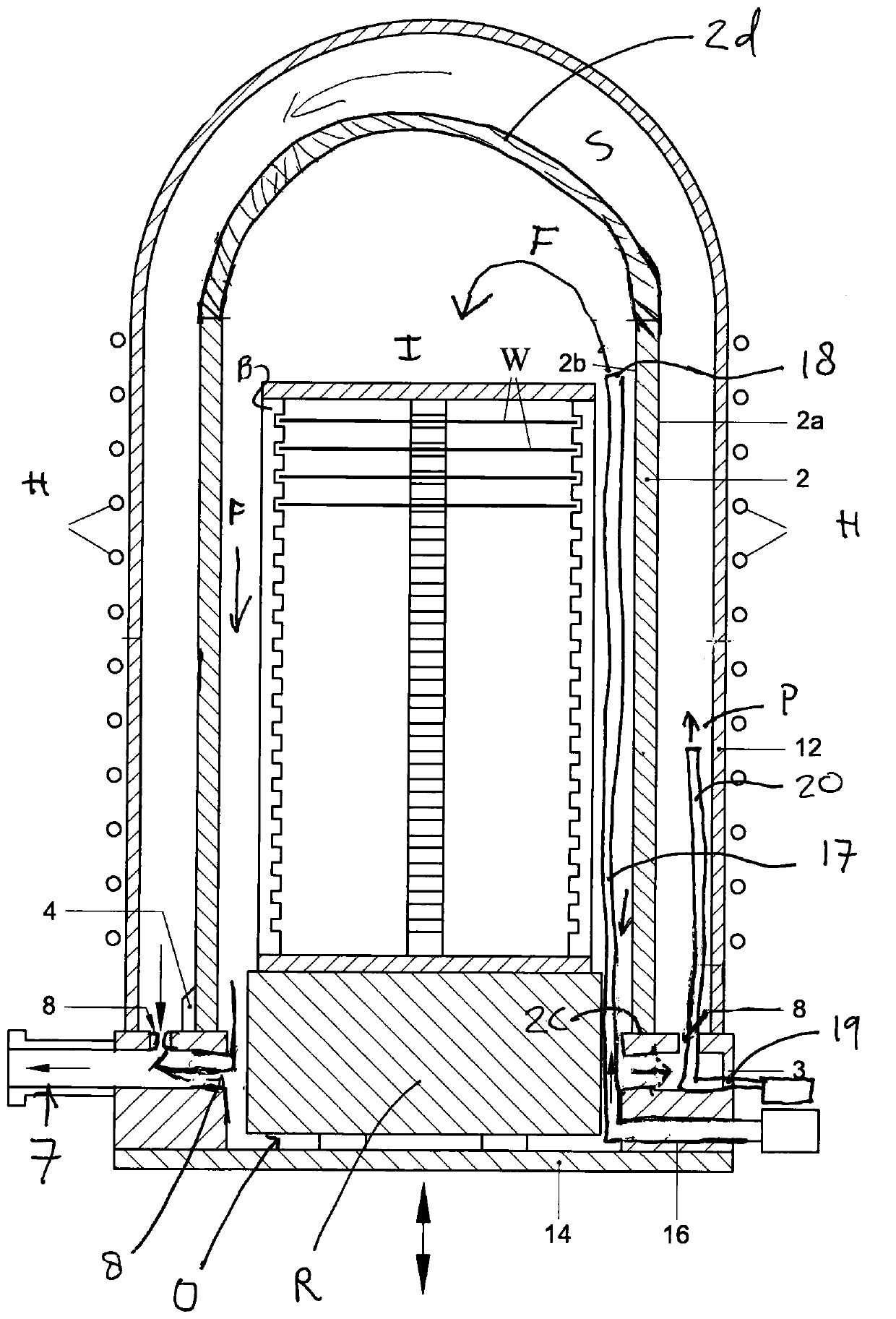

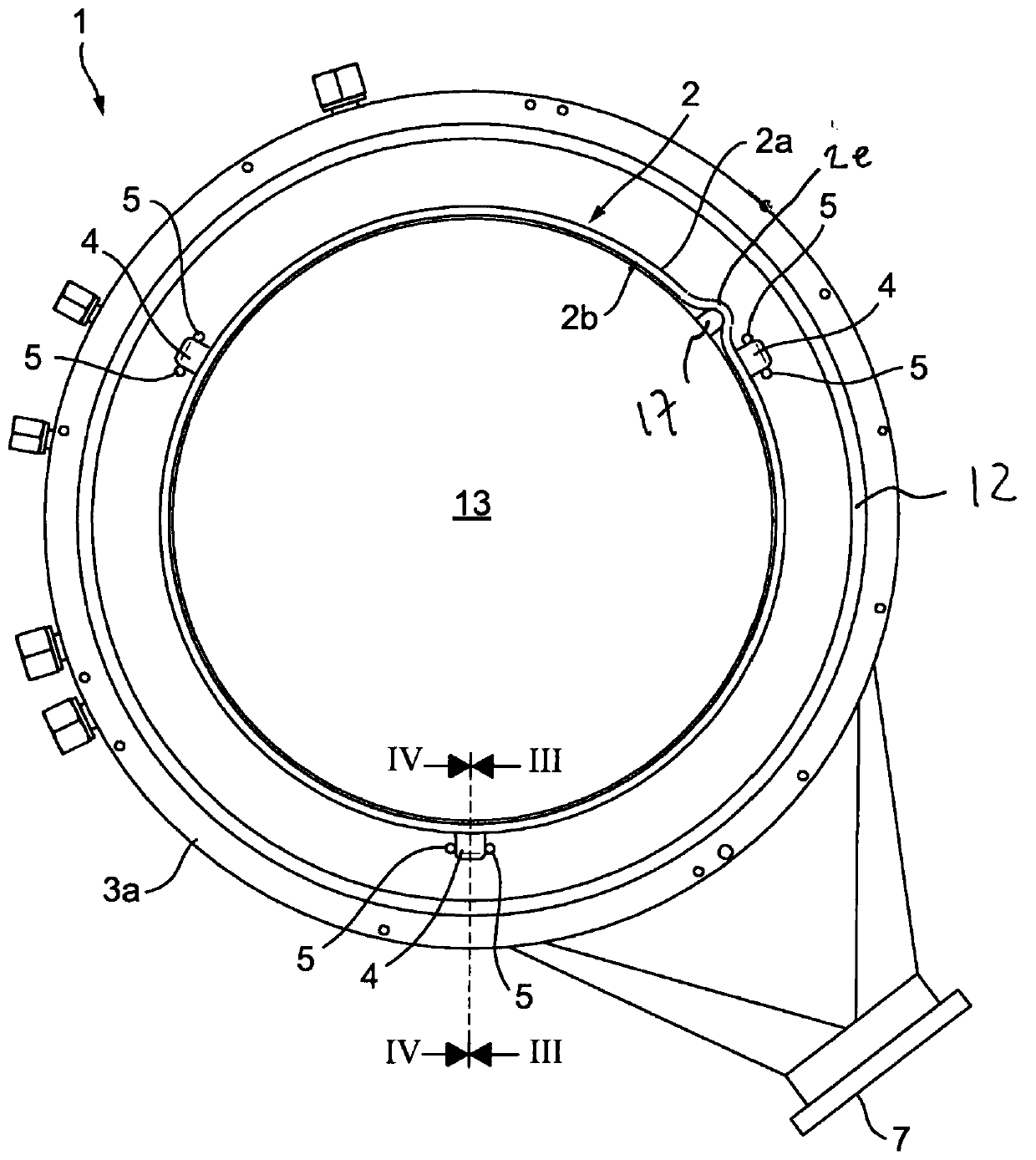

[0029] figure 1 A cross-sectional view of a shaft furnace including a liner and flange assembly according to an embodiment is shown. The shaft furnace includes a low-pressure process tube 12 defining an interior and a heater H configured to heat the interior.

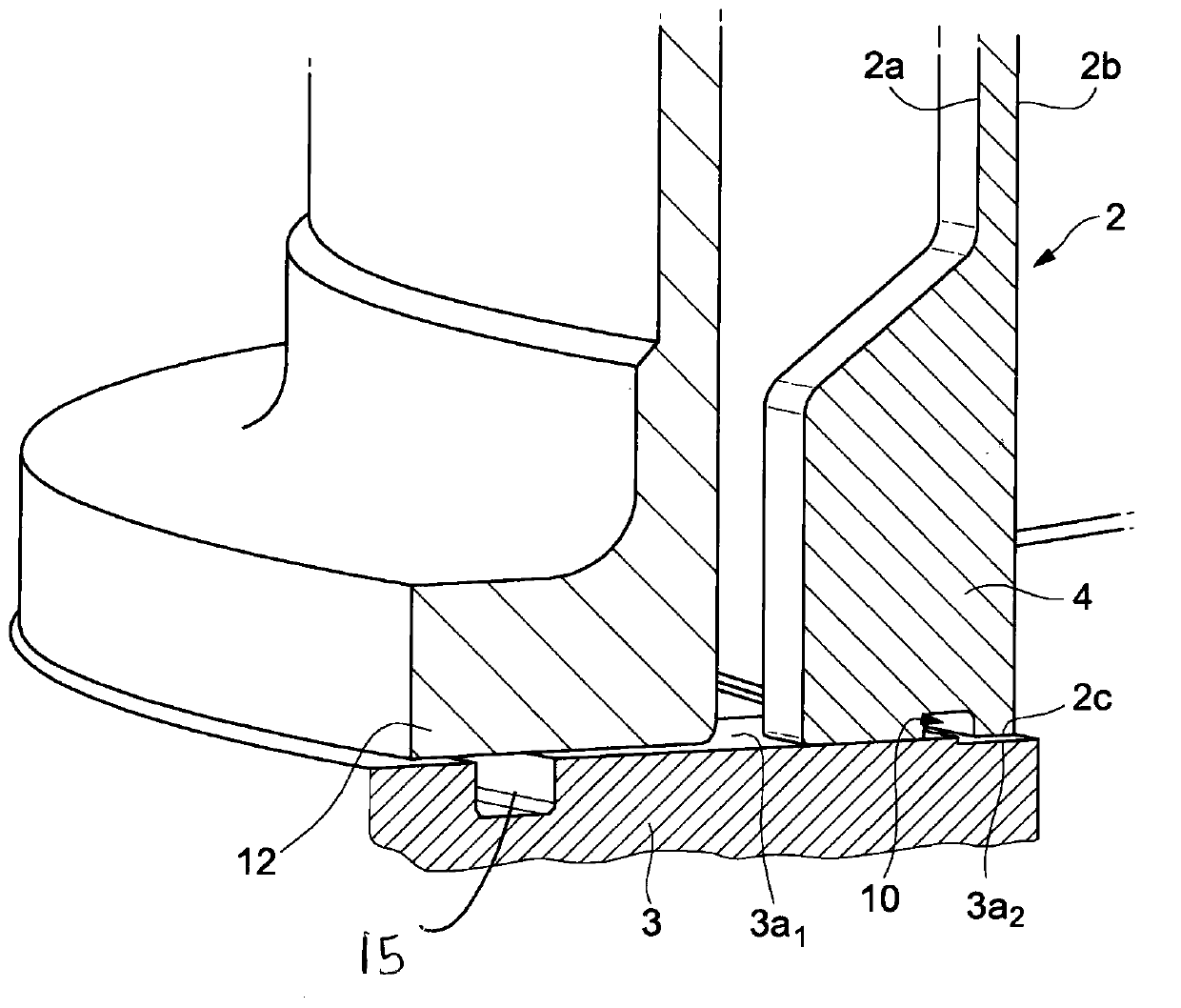

[0030] Extending in the interior is a liner 2 comprising a substantially cylindrical wall delimited by a liner opening at a lower end and a dome-shaped top closure 2d at a higher end. The liner is substantially closed to the gas above the opening of the liner and defines an inner space I.

[0031] A flange 3 may be provided to at least partially clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com