Non-welding modular assembly type treadmill and assembly method thereof

A modular and assembled technology, applied in the field of treadmills, can solve problems such as human harm, environmental pollution, and short service life, and achieve the effects of environmental protection in the production environment, good structural strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

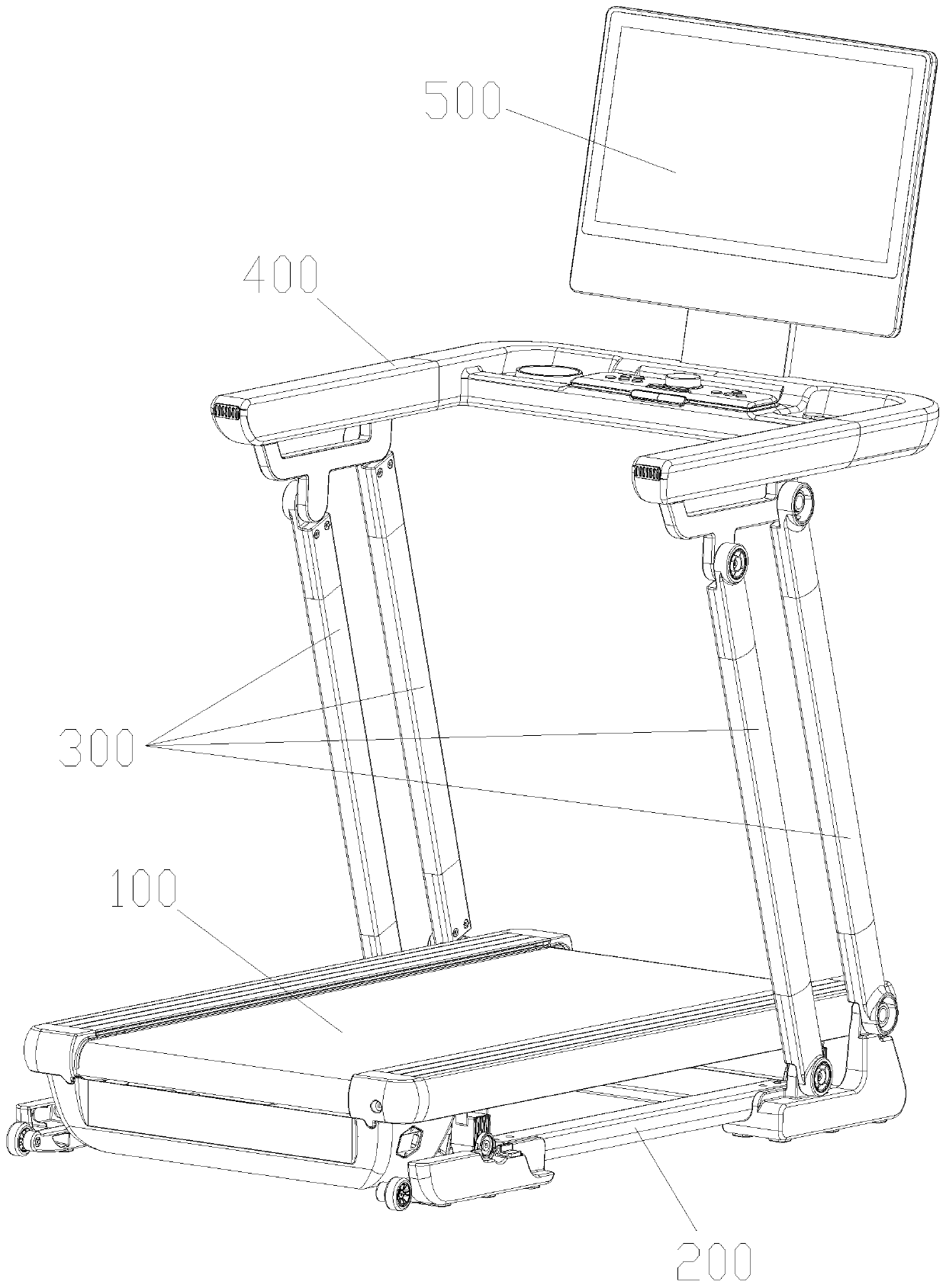

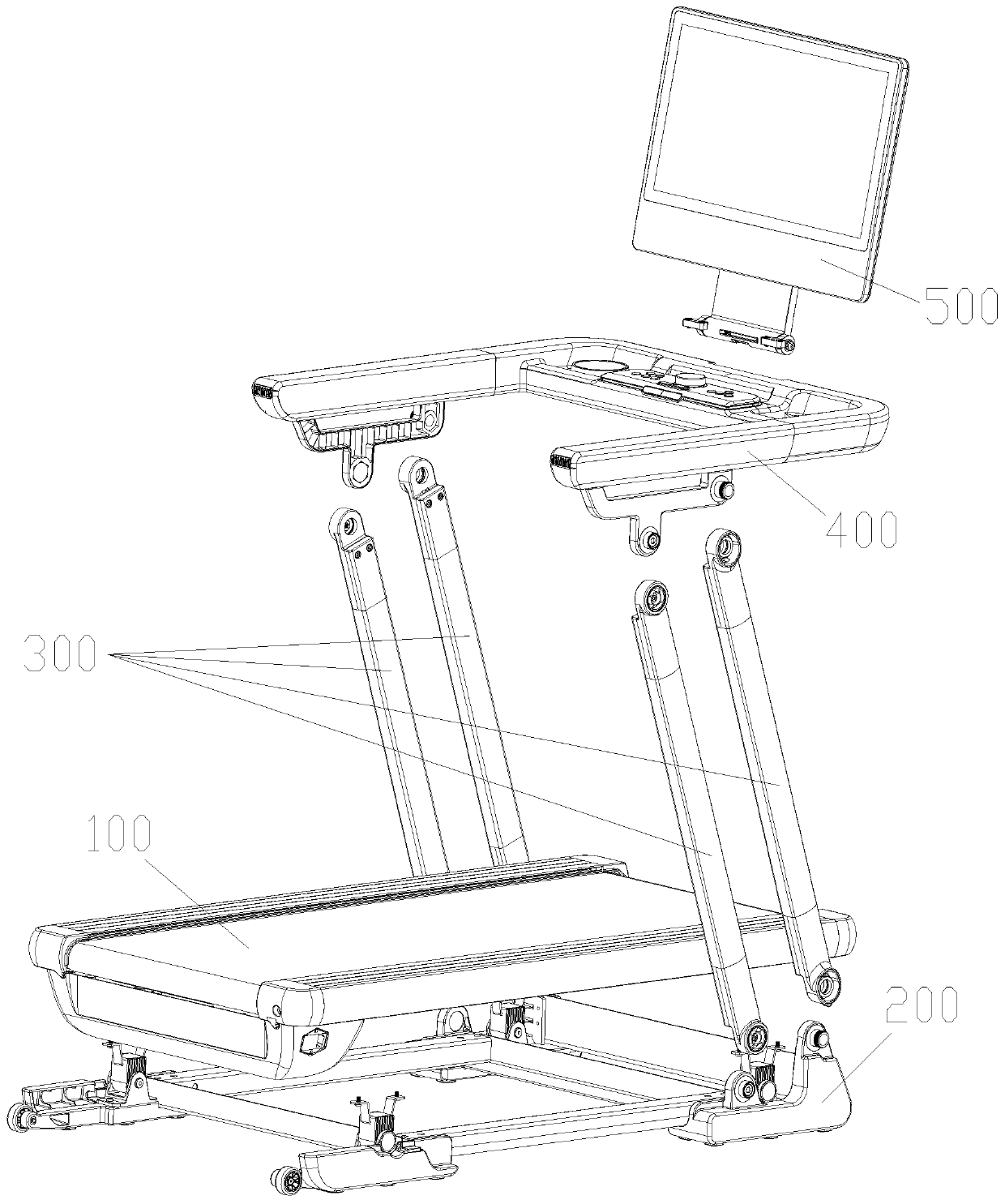

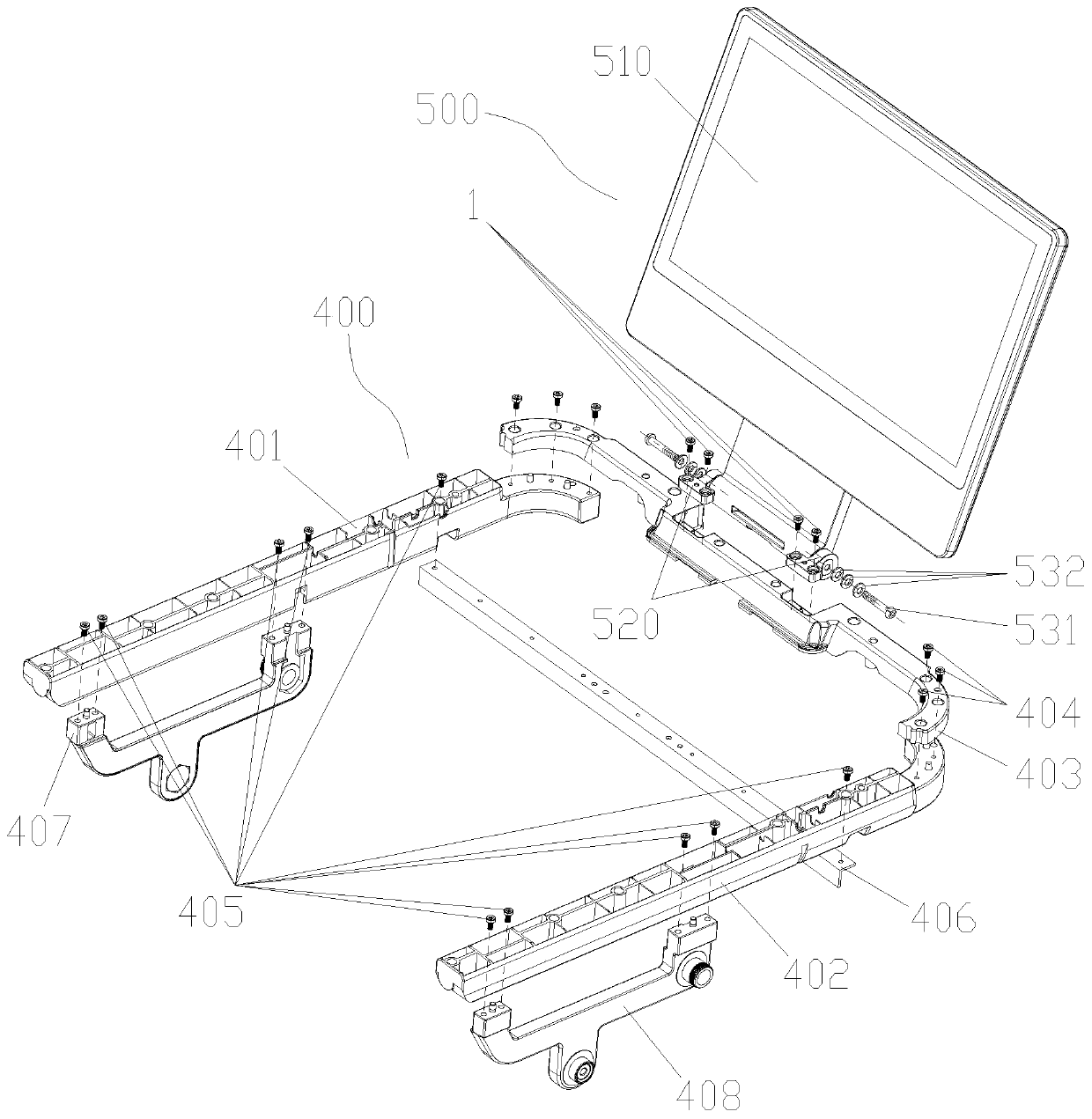

[0027] Such as Figure 1-8 As shown, the present embodiment provides a non-welded modular assembly type treadmill, including a display assembly module 500, a dial assembly module 400, a column assembly module 300, a bottom frame assembly module 200 and a treadmill assembly module 100, the running The bottoms on both sides of the table assembly module 100 are detachably and elastically connected to the bottom frame assembly module 200, the lower end of the column assembly module 300 is detachably fixedly connected to both sides of the front end of the bottom frame assembly module 200, and the dial assembly module 400 The bottom of the rear end of the display assembly module 500 is detachably fixedly connected to the upper end of the column assembly module 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com