Correcting method of injection condition of die casting machine based on molten material supply

A technology of die casting machine and supply quantity, which is applied to the configuration of indicating equipment/measuring equipment, casting equipment, and manufacturing tools, etc., can solve problems such as changes in molten material quantity, and achieve the effect of avoiding quality deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

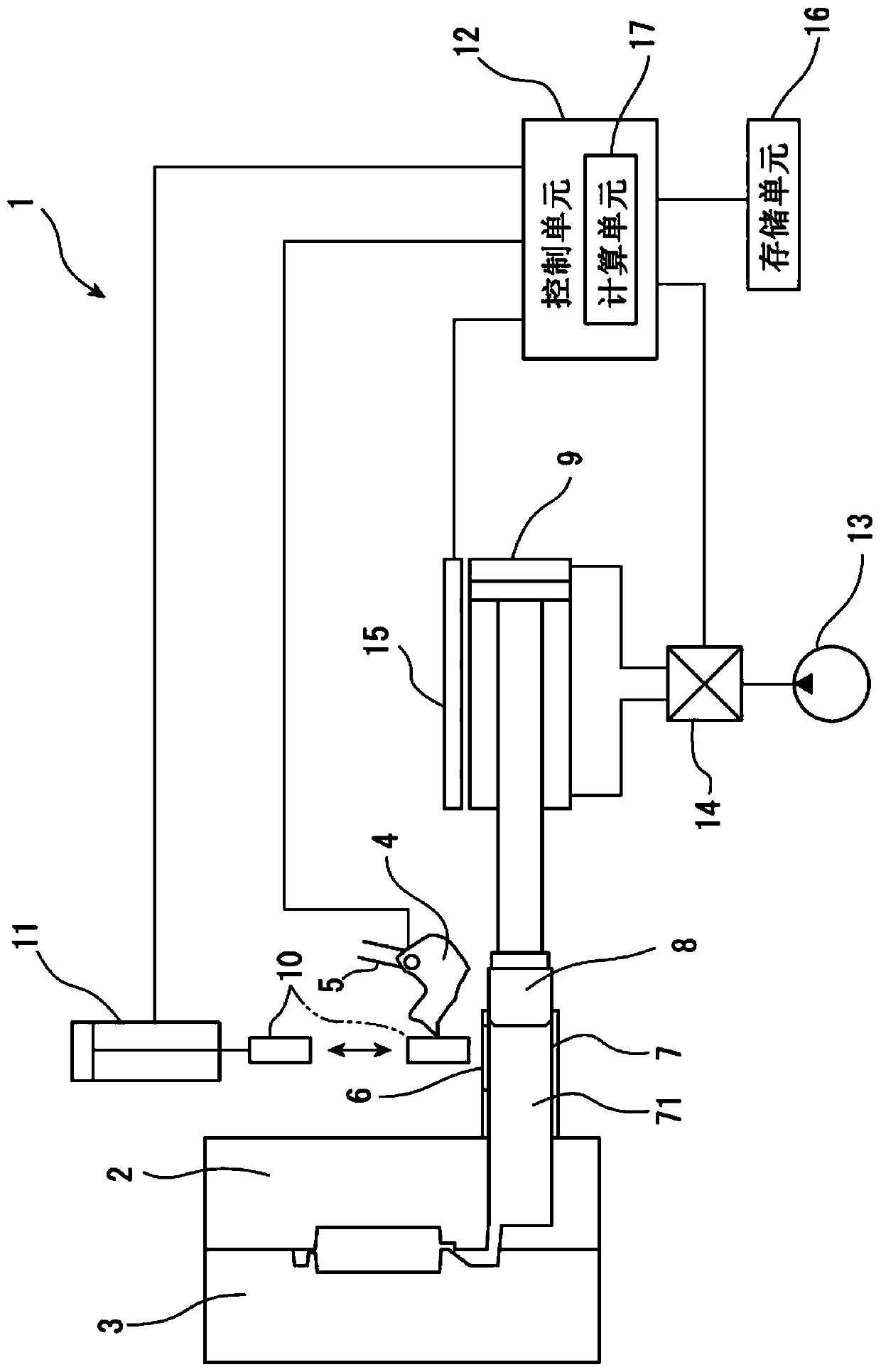

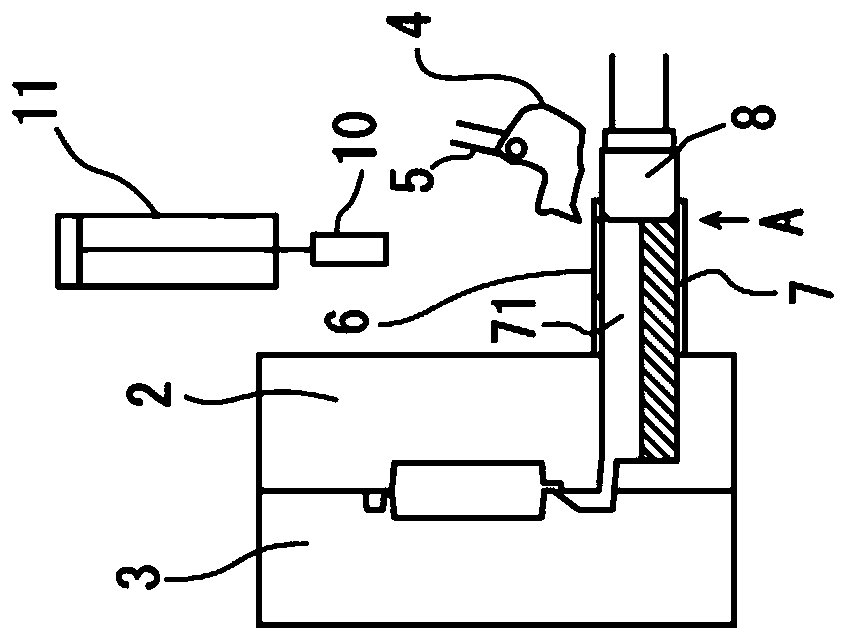

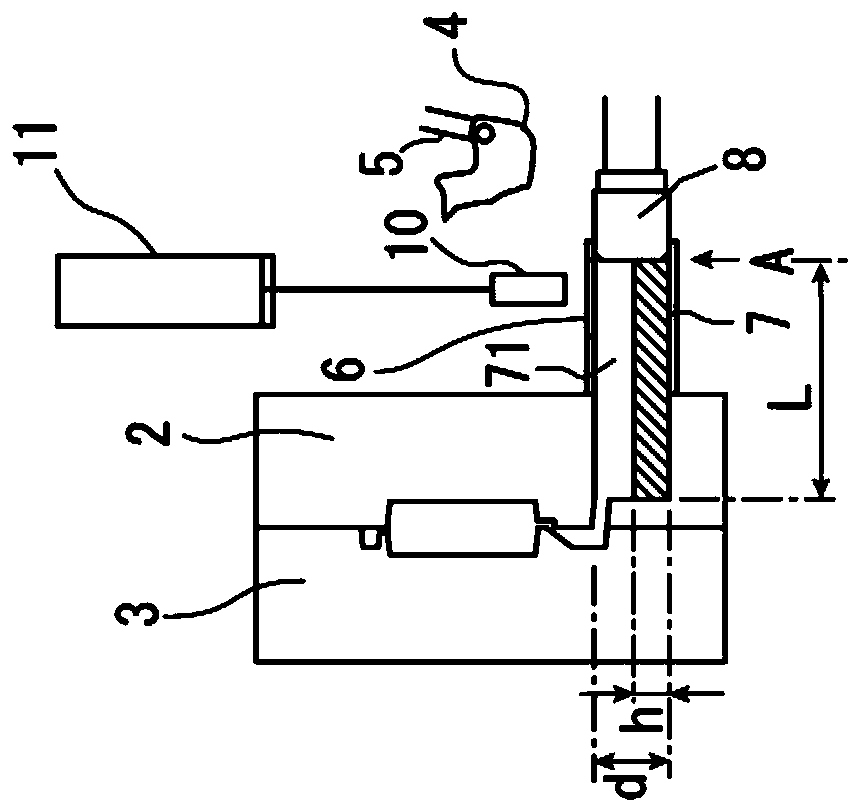

[0059] Below, based on Figure 1 to Figure 6 An example of a specific configuration of a die-casting machine according to an embodiment of the present invention and a method of correcting injection conditions of the die-casting machine based on the directly measured molten material supply amount will be described. Of course, the present invention is not limited to the specific embodiments described in the present examples, and can be easily applied to other configurations that can be easily changed by those skilled in the art, within the range that does not violate the gist of the present invention.

[0060] In the die-casting machine used in the method of correcting injection conditions of the present invention, the height of the molten material surface of the molten material actually supplied to the injection sleeve is measured, and calculation is performed based on the measurement results to measure the molten material actually supplied to the injection sleeve. The amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com