Crimping device for terminal and method of use

A crimping device and terminal technology, applied in the direction of connection, electrical components, circuits, etc., can solve the problems of inability to meet production requirements, low work efficiency, relying on manual operation, etc., to improve practicability, reduce labor intensity, and simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

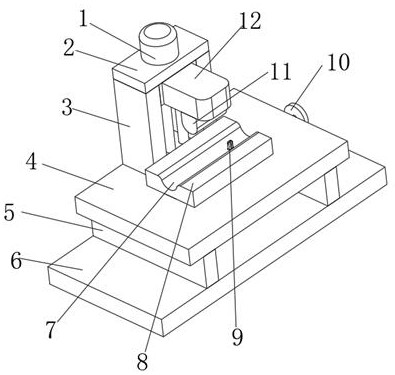

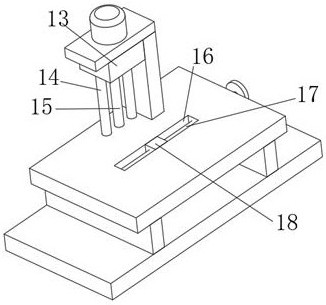

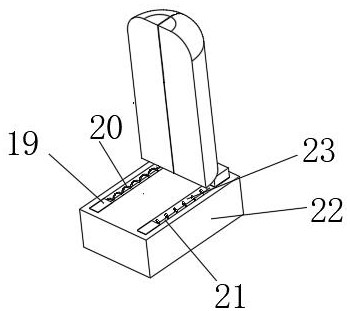

[0025] Example: refer to Figure 1-3 , a crimping device for terminals, including a bottom plate 6, the top of the bottom plate 6 is welded with a support base 5, the number of support bases 5 is two groups and arranged in parallel, and the top of the support base 5 is welded and installed with a base plate 4, the base plate The top of 4 is welded with a support plate 3, the number of support plates 3 is two groups and arranged in parallel, the top of the support plate 3 is welded with a top plate 2, the top plate 2 and the base plate 4 are arranged in parallel, and the corresponding side of the top plate 2 and the base plate 4 The first threaded rod 15 is mounted on the wall rotation, and the corresponding side walls of the top plate 2 and the base plate 4 are located on both sides of the first threaded rod 15, and the first sliding rod 14 is welded and installed. The upper sleeve is provided with a movable block 13, the movable block 13 is slidably connected with the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com