A high-strength double-layer hollow plastic plate production device

A double-layer hollow and plastic sheet technology, applied in the field of plastic sheets, can solve the problems of uneven quality levels of double-layer hollow plastic sheets, the strength of plastic sheets cannot be too low, and equipment debugging is different, so as to avoid quality deviation and automate High-level, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

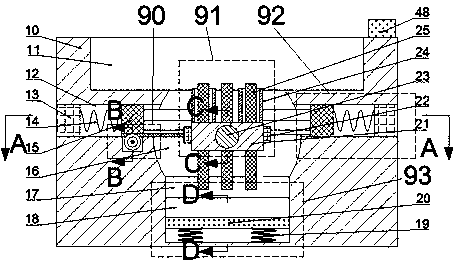

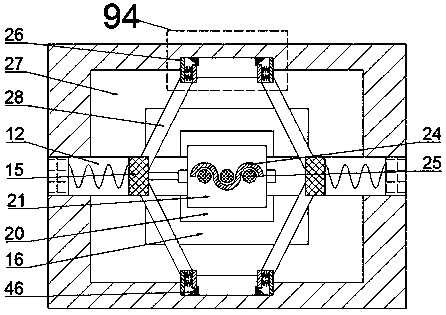

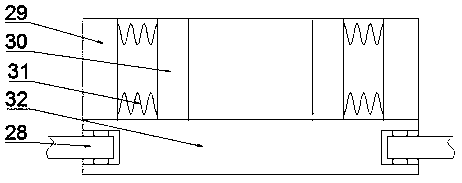

[0025] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026] combined with Figure 1-6 The mechanical structure of a high-strength double-layer hollow plastic plate production device mainly includes a heating rotation mechanism 91 , an electromagnetic sliding mechanism 92 , a strength testing component 93 , an extrusion mechanism 94 and a ratchet transmission mechanism 95 .

[0027] The above-mentioned electromagnetic sliding mechanism 92 can make the above-mentioned extruding mechanism 94 extrude the above-mentioned heating and rotating mechanism 91 to form a double-layer hollow plastic plate. The mechanism 95 drives the above-mentioned heating and rotating mechanism 91 to vertically pour the double-layer hollow plastic plate into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com