Dual-layer washing machine drainage pipe and extruder handpiece of washing machine drainage pipe

A technology for drainage pipes and washing machines, which is applied to other washing machines, washing devices, tubular objects, etc. It can solve the problems of short service life, only single-layer material embryos can be extruded, and regular replacement, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

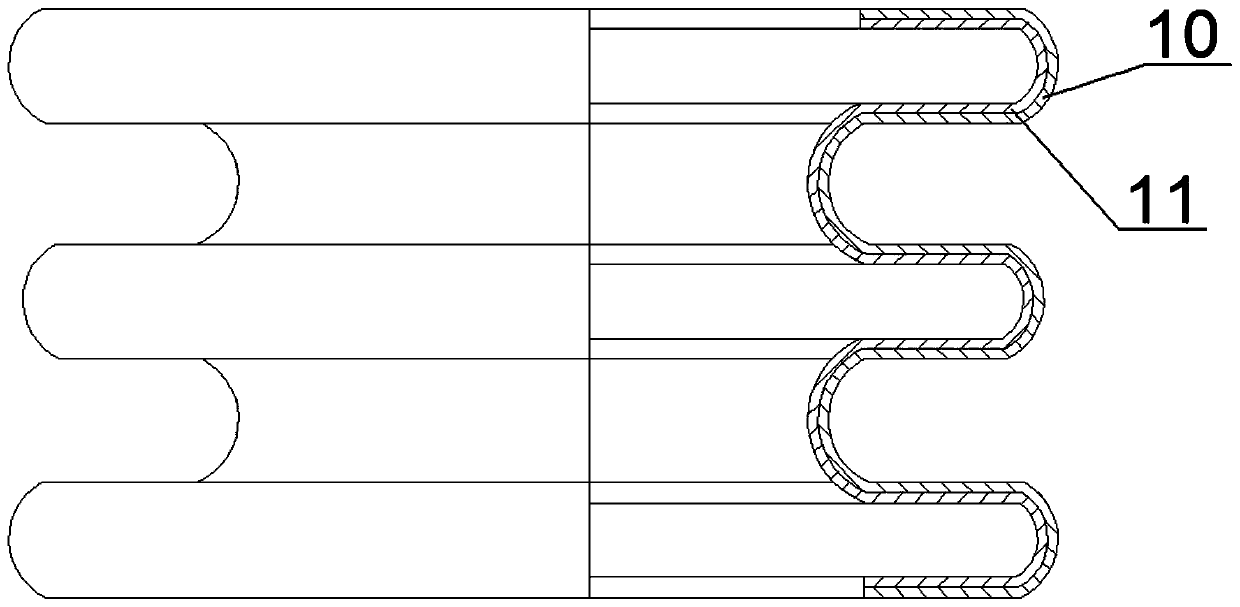

[0033] A double-deck drain, such as figure 1 As shown, the drain pipe includes an outer drain pipe 10 and an inner drain pipe 11 , the outer drain pipe 10 is sheathed outside the inner drain pipe 11 and bonded and fixedly connected with the inner drain pipe 11 . Specifically, the outer drainage pipe 10 and the inner drainage pipe 11 are integrally formed.

[0034] The double-deck drain pipe is a telescopic pipe or a corrugated pipe.

Embodiment 2

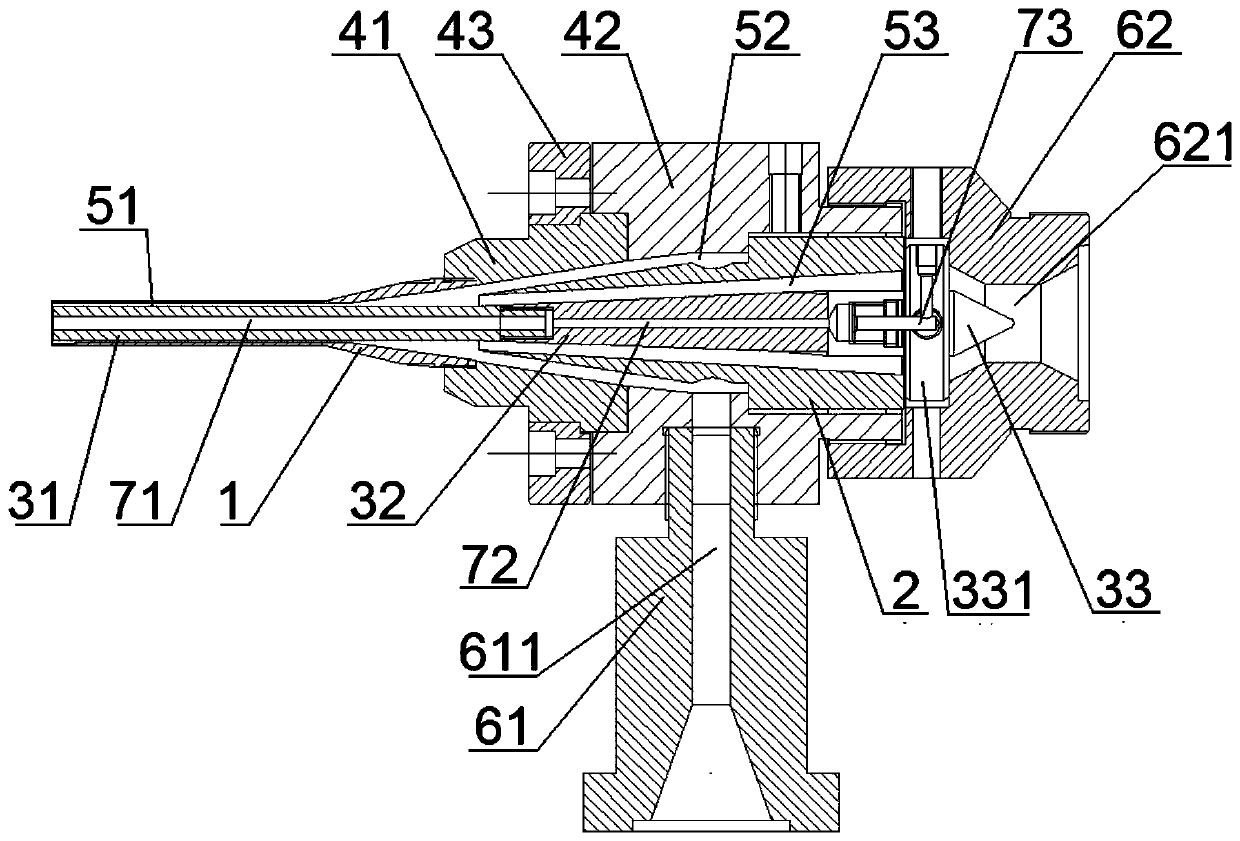

[0036] A washing machine drain pipe extruder head, such as Figure 2 to Figure 6As shown, it includes a die 1, an outer mold assembly, a core mold 31 assembly and a flow divider 2; the die 1 is provided with a first cavity that runs through the left and right ends of the die 1, and the outer die assembly is provided with a penetrating outer die The second cavity at the left and right ends of the assembly, the inside of the shunt 2 is provided with a third cavity that runs through the left and right ends of the shunt 2, the rear end of the die 1 is fixedly connected with the front end of the outer mold assembly, and the core mold 31 assembly includes sequentially Fixedly connected mandrel 31, mandrel base 32 and diverter shuttle 33, the rear end of diverter shuttle 33 is fixedly connected with the outer mold assembly, mandrel 31 is located in the first cavity of die 1 and forms a gap between die 1 and The extrusion channel 51, the splitter 2 is located in the second cavity of t...

Embodiment 3

[0042] This embodiment is a more specific implementation of Embodiment 1. In this embodiment,

[0043] The outer mold assembly includes a nose plate 43, a die base 41 and an outer mold body 42, and the first cavity runs through the two ends of the die base 41 and the outer mold body 42 in sequence,

[0044] The rear end of the outer mold body 42 is provided with a first external thread, and the front end of the second feed connector 62 is provided with a first internal thread compatible with the first external thread, and the outer mold body 42 and the second feed connector 62 is fixed by screwing the first internal thread and the first external thread,

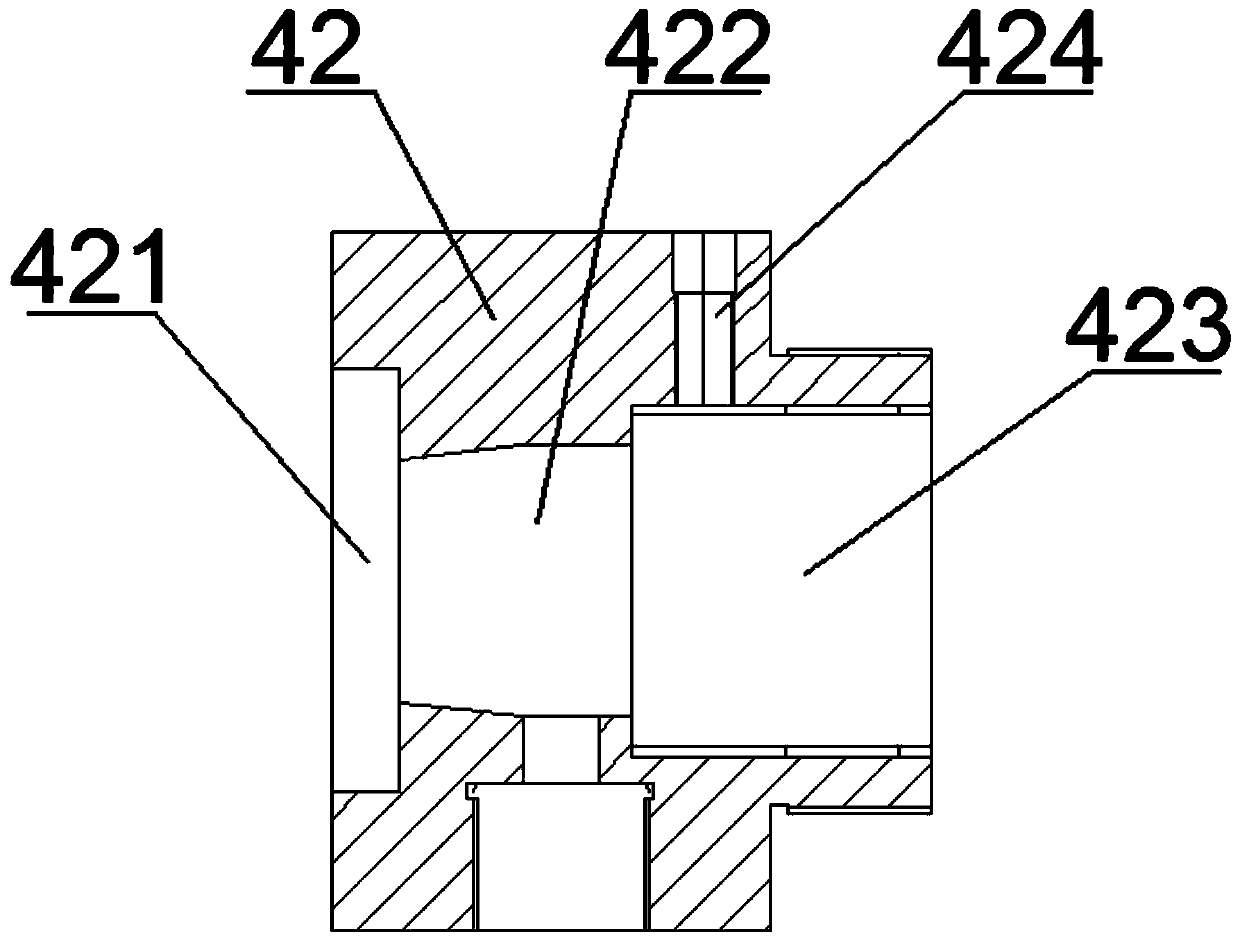

[0045] The second chamber comprises a first chamber 421, a second chamber 422 and a third chamber 423 which are communicated sequentially from left to right, the third chamber 423 is circular and the third chamber 423 is connected to the first chamber 423. An external thread is coaxially arranged, and the rear end of the div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com