Spiral titanium dioxide photoelectrode and preparation method and application thereof

A technology of titanium dioxide and photoelectrode, which is applied in the field of semiconductor photocatalysis, can solve problems such as limited application capabilities, and achieve the effects of easy operation, tube wall thickness, and tube diameter calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of helical titanium dioxide photoelectrode material, its preparation method specifically comprises the following steps:

[0032] (1) Cut a commercial titanium sheet (99.99% pure) into a size of 20 × 20 × 0.5 mm, and then ultrasonically clean it with acetone (30 mL), isopropanol (30 mL) and distilled water (30 mL) for 10 min. , chemical polishing in 30 mL of a mixed solution containing hydrofluoric acid, nitric acid and distilled water (the volume ratio of hydrofluoric acid, nitric acid and distilled water is 1:4:5, the mass fraction of hydrofluoric acid is 40%, and the mass fraction of nitric acid is 65%) After taking it out for 3 minutes, it was ultrasonically cleaned with distilled water for 3 times, and finally dried with high-purity nitrogen to obtain a titanium sheet with a clean and smooth surface.

[0033] (2) Prepare 60 mL of electrolyte solution containing ammonium fluoride, glycerin and distilled water, the volume ratio of glycerin and distilled water i...

Embodiment 2

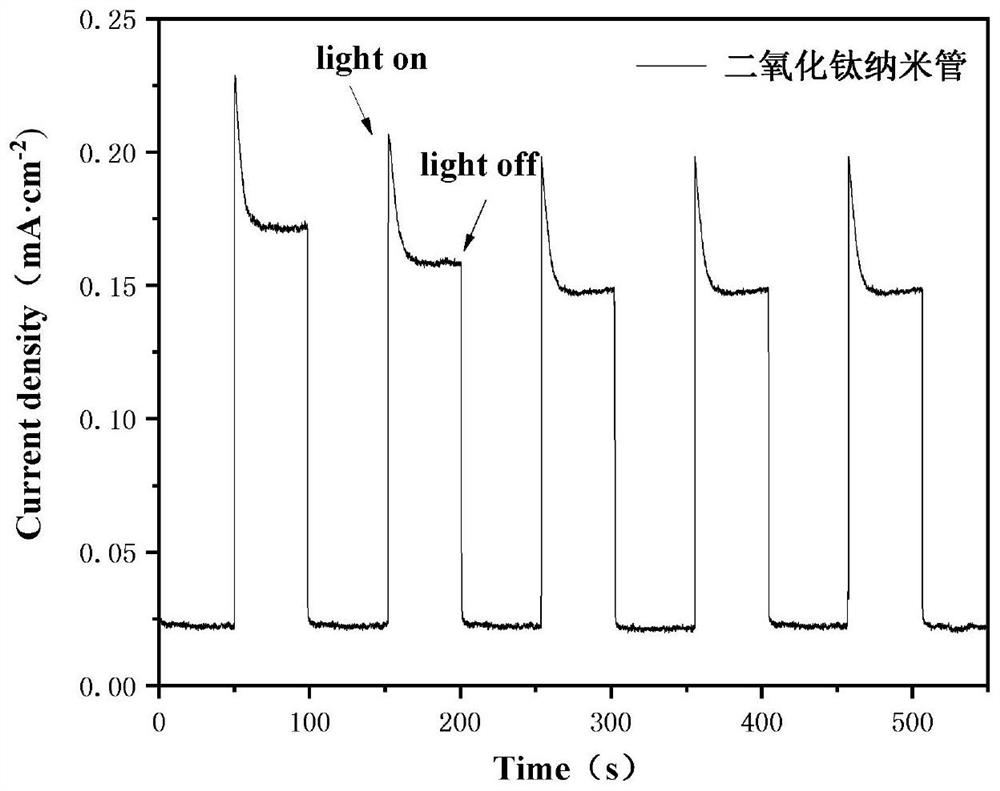

[0041] The experimental process repeats the operation steps of Example 1, the difference is only that "the operation process of step (4) is replaced by: only use a DC power supply to react at a voltage of 30V for 2h", and the rest of the operations are the same as in Example 1. That is to say, the present embodiment 2 is compared with the embodiment 1, except that the electric pulse method is not used to adjust the electrochemical anodic oxidation process in the present embodiment 2, other processes are all the same as the embodiment 1, finally made titanium dioxide nanotubes photoelectrode.

Embodiment 3

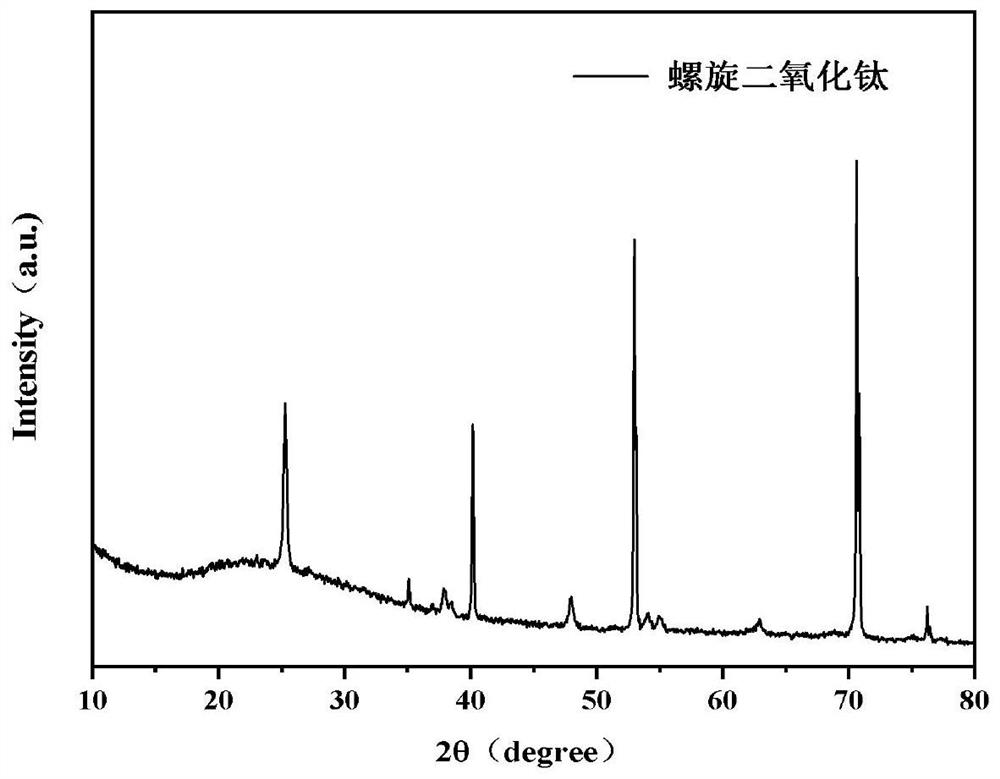

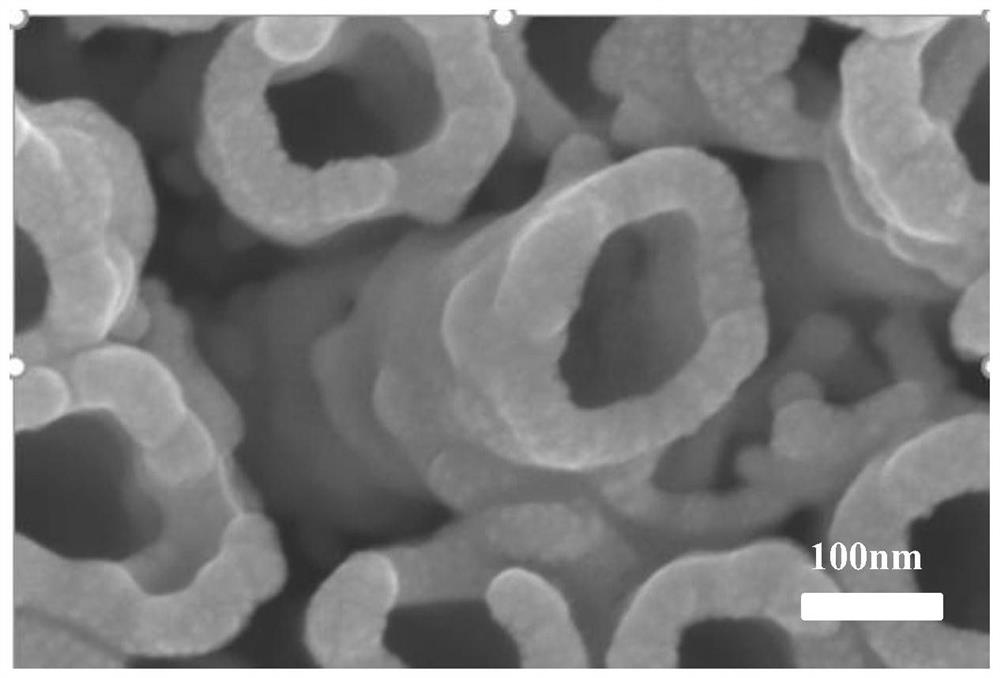

[0043] The experimental process repeats the operation steps of Example 1, the difference is only that "the operation process of step (4) is replaced by: the electric pulse frequency is set by the timing switch to be 5s after every energization, and the power is turned off for 5s until the reaction ends, and the DC power supply voltage is adjusted. was 30 V, the total effective energization time was 2 h, and the electrochemical pulse anodic oxidation reaction was carried out", and the rest of the operations were the same as in Example 1, and finally an anatase helical titanium dioxide photoelectrode was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com