preparation of double-walled na 2 (tio)sio 4 Nanotube approach

A nanotube and double-wall technology, applied in the field of Na2SiO4 nanotube preparation, achieves high tube forming rate, simple operation, and controllable tube length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

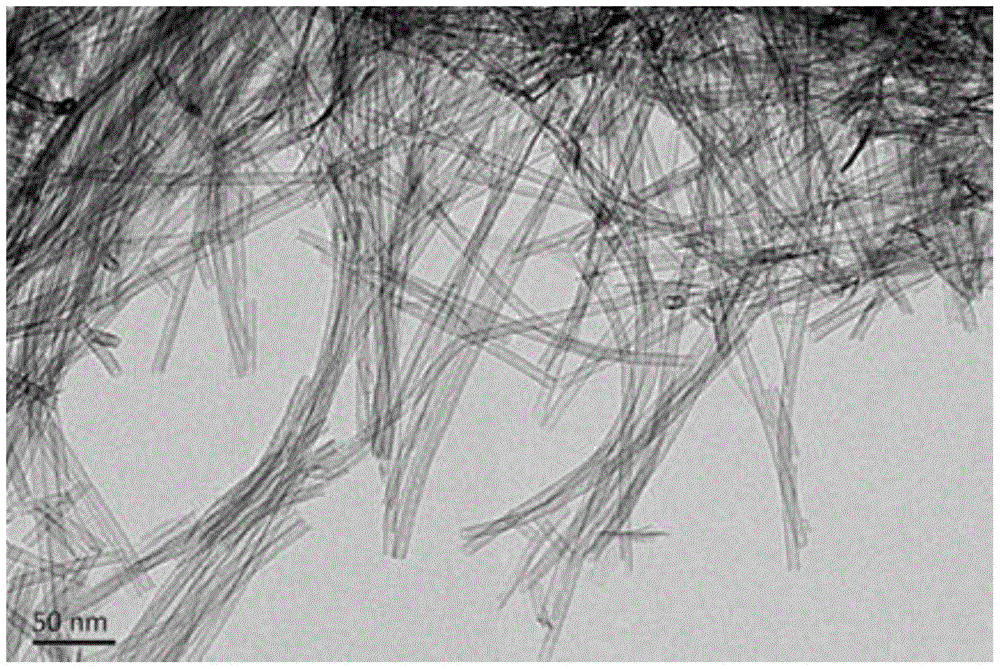

[0038] Embodiment 1: Si: Ti=1 composite powder is the double-walled Na that raw material prepares 2 (TiO)SiO 4 nanotube

[0039] Weigh 5 g of titanyl sulfate into a beaker, add 45 g of distilled water, and stir to form a solution.

[0040]Add 10 g of silica sol dropwise to the above solution, stir, and add ammonia water dropwise until the pH value is between 10 and 12.

[0041] The above mixture was allowed to stand at room temperature for 24 h, and then dried in an oven at 120° C. for 12 h.

[0042] The dried powder was calcined at 450°C for 4h. prepared SiO 2 -TiO 2 Composite powder.

[0043] Take 20mL of NaOH solution with a concentration of 10mol / L and add it to the lining of the polytetrafluoroethylene reactor.

[0044] Weigh 1 g of cetyltrimethylammonium bromide and 2 g of the above-prepared nanocomposite powder, add them to the sodium hydroxide solution, and ultrasonicate them to make them evenly mixed.

[0045] Put the stainless steel reaction kettle into an ov...

Embodiment 2

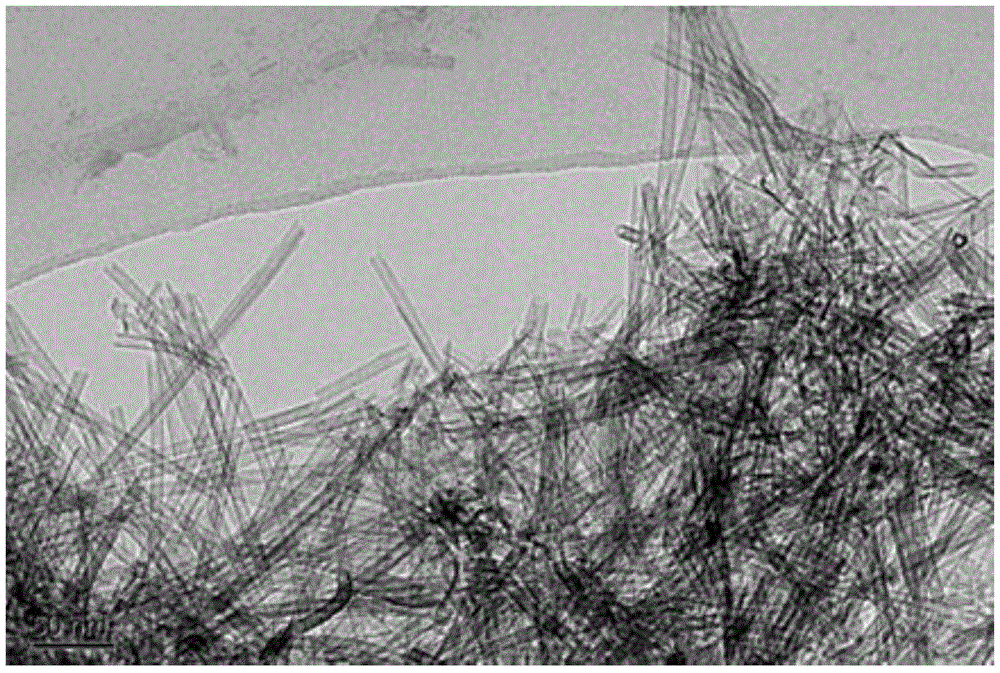

[0052] Embodiment 2: Si:Ti=2 composite powder is the double-walled Na that raw material prepares 2 (TiO)SiO 4 nanotube

[0053] Weigh 10 g of titanyl sulfate into a beaker, add 45 g of distilled water, and stir to form a solution.

[0054] Add 10 g of silica sol dropwise to the above solution, stir, and add ammonia water dropwise until the pH value is between 10 and 12.

[0055] The above mixture was allowed to stand at room temperature for 24 h, and then dried in an oven at 120° C. for 12 h.

[0056] The dried powder was calcined at 450°C for 4h. prepared SiO 2 -TiO 2 Composite powder.

[0057] Take 20mL of NaOH solution with a concentration of 10mol / L and add it to the lining of the polytetrafluoroethylene reactor.

[0058] Weigh 1 g of cetyltrimethylammonium bromide and 2 g of the above-prepared nanocomposite powder, add them to the sodium hydroxide solution, and ultrasonicate them to make them evenly mixed.

[0059] Put the stainless steel reaction kettle into an o...

Embodiment 3

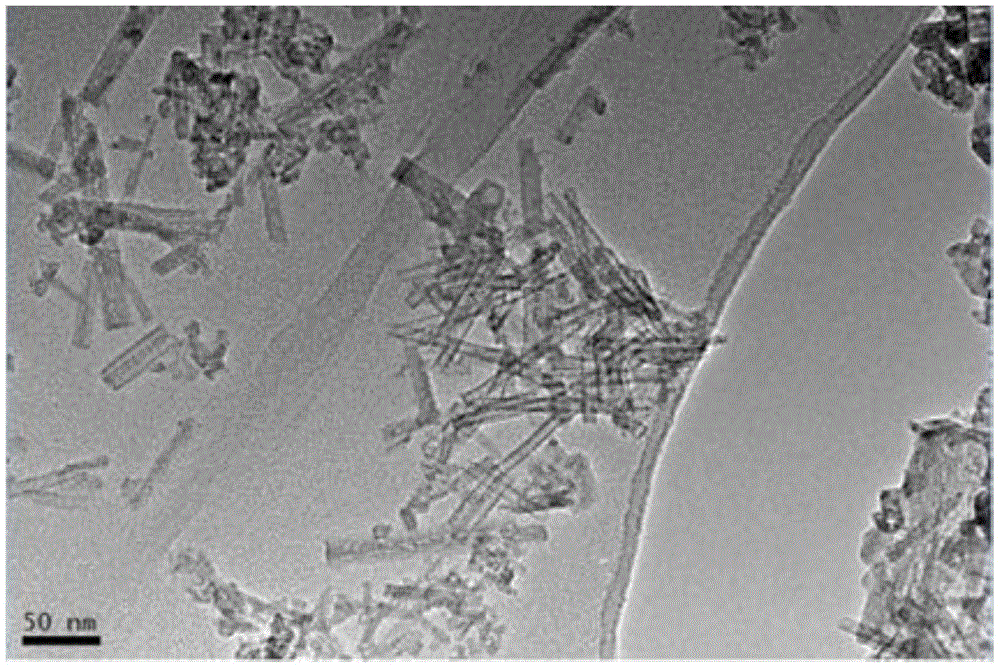

[0066] Embodiment 3: Si:Ti=3 composite powder is the double-walled Na that raw material prepares 2 (TiO)SiO 4 nanotube

[0067] Weigh 15 g of titanyl sulfate into a beaker, add 45 g of distilled water, and stir to form a solution.

[0068] Add 10 g of silica sol dropwise to the above solution, stir, and add ammonia water dropwise until the pH value is between 10 and 12.

[0069] The above mixture was allowed to stand at room temperature for 24 h, and then dried in an oven at 120° C. for 12 h.

[0070] The dried powder was calcined at 450°C for 4h. prepared SiO 2 -TiO 2 Composite powder.

[0071] Take 20mL of NaOH solution with a concentration of 10mol / L and add it to the lining of the polytetrafluoroethylene reactor.

[0072] Weigh 1 g of cetyltrimethylammonium bromide and 2 g of the above-prepared nanocomposite powder, add them to the sodium hydroxide solution, and ultrasonicate them to make them evenly mixed.

[0073] Put the stainless steel reaction kettle into an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com